High-activity granulated blast furnace slag and preparation method thereof

A slag micropowder, high activity technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of low activity, limited application field, single function, etc., to reduce the water-to-binder ratio, reduce Room temperature, rapid development effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

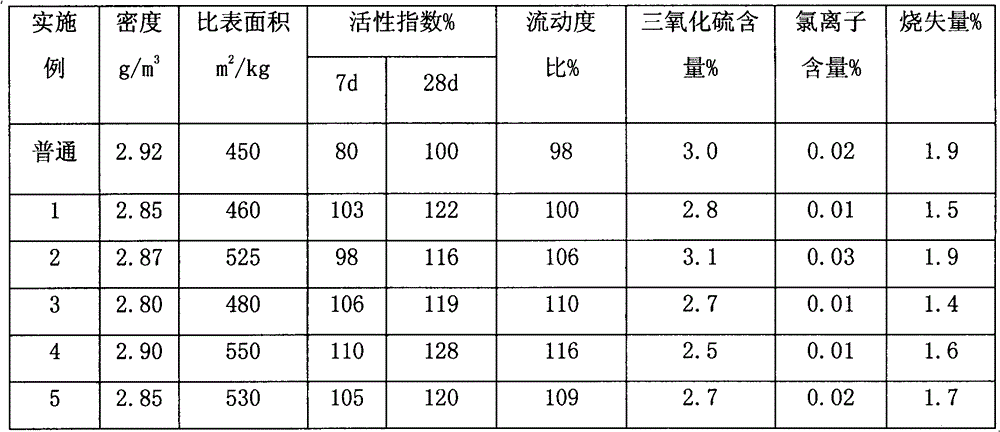

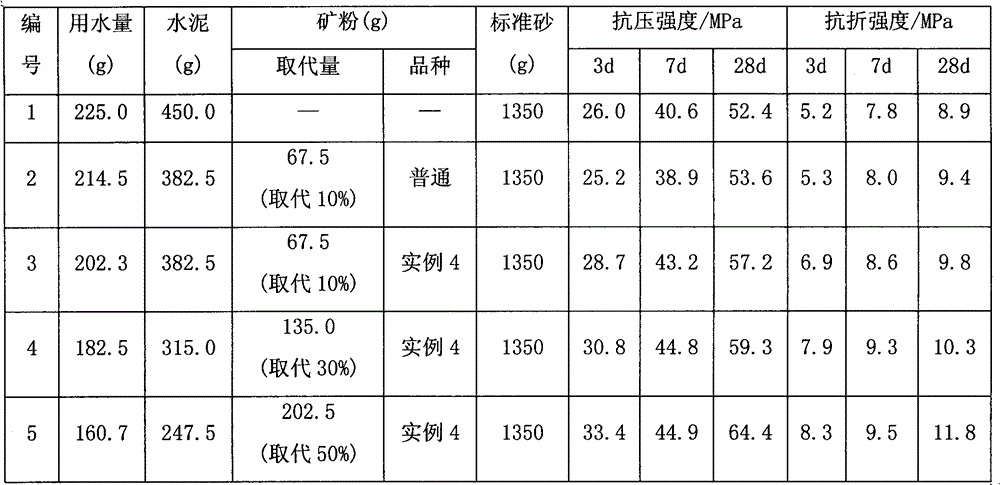

Embodiment 1

[0019] Embodiment 1: A kind of highly active slag micropowder, which is obtained by co-grinding granulated blast furnace slag mixed with 10% solid synergist. The proportioning of the solid synergist is (percentage by weight): 15% of microsilica, 59% of natural ground gypsum, 20% of highly active calcium oxide, 1% of triethanolamine, and 5% of sodium silicate.

Embodiment 2

[0020] Example 2: A highly active slag micropowder, which is obtained by grinding together 20% solid synergist in granulated blast furnace slag. The ratio of the solid synergist is (percentage by weight): 50% ultrafine fly ash, 10% natural ground gypsum, 5% desulfurized gypsum, 30% highly active calcium oxide, 1% triisopropanolamine, silicic acid Potassium 2% and sodium silicate 2%.

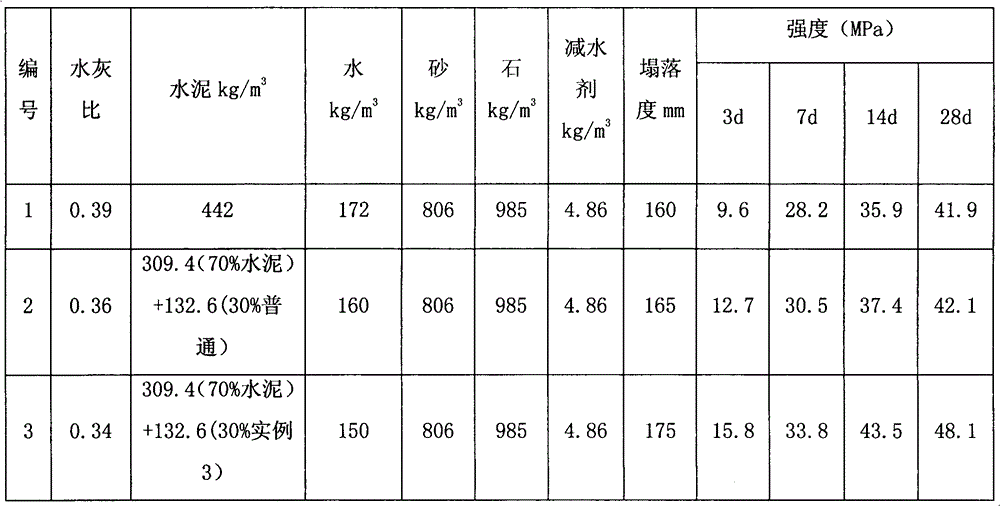

Embodiment 3

[0021] Embodiment 3: A kind of highly active slag micropowder, which is obtained by co-grinding granulated blast furnace slag mixed with 30% solid synergist. The ratio of the solid synergist is (percentage by weight): microsilica fume 10%, superfine fly ash 17%, desulfurized gypsum 10.2%, highly active calcium oxide 60%, triethanolamine 1%, triisopropanolamine 1% % and potassium silicate 0.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com