Carbon/carbon heater preparation method based on atmosphere high-temperature furnace thermal field system

A heater and high-temperature furnace technology, which is applied in the field of carbon/carbon heater preparation, can solve problems such as easy occurrence of electric arcing, and achieve the effects of improving gas erosion resistance, highlighting substantive features and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

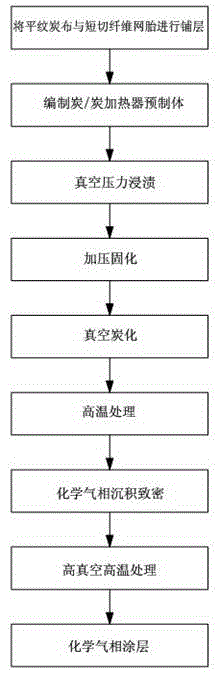

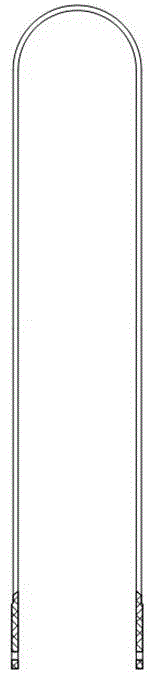

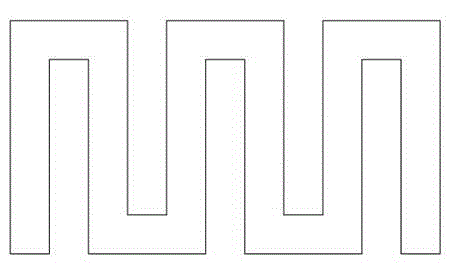

[0045] Such as figure 1 As shown, the preparation method of the carbon / carbon heater based on the thermal field system of the atmosphere high-temperature furnace uses plain carbon cloth and chopped fiber mesh tire as the matrix of the carbon / carbon heater preform, and it is made by the acupuncture process Carbon / carbon heater prefabricated body, and then through vacuum pressure impregnation process, pressure curing process, vacuum carbonization treatment process, high temperature treatment process, chemical vapor deposition densification process, high vacuum high temperature treatment process, mechanical processing process and chemical vapor phase coating process The charcoal / charcoal heater preform is made into the final product. Its preparation process is as follows:

[0046] (1) Lay the plain carbon cloth and the chopped fiber mesh tire according to the stacking method of plain carbon cloth-chopped fiber mesh tire-plain carbon cloth;

[0047] (2) Make the prefabricated ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com