Preparation process for producing tobacco organic compound fertilizer by utilizing animal manure

A technology of livestock and poultry manure and preparation process, which is applied in the preparation of organic fertilizer, organic fertilizer, biological organic part treatment, etc. Diseases, the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

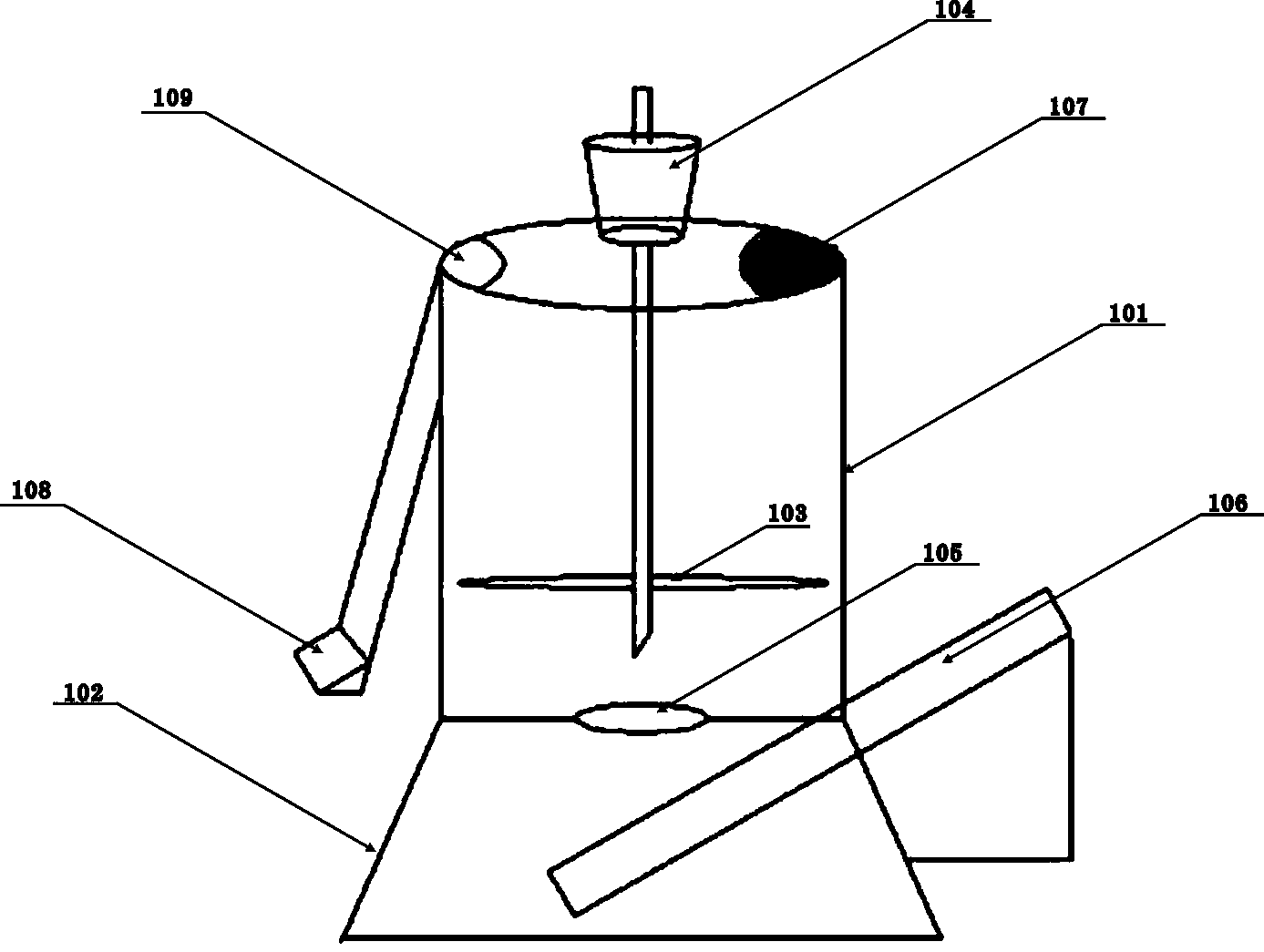

[0021] The present invention is described in detail below in conjunction with accompanying drawing:

[0022] The utility model hereby provides a preparation process for making tobacco organic compound fertilizer by using livestock and poultry manure,

[0023] The first stage of fermentation process: fresh pig manure is mixed with straw or bacteria residue, and then added to a stainless steel fermentation tank for fermentation operation, heated to 70-90 degrees in the fermentation tank, and bacteria are added for stirring operation during the heating process , Stir to make the temperature of the content uniform, kill harmful bacteria and eggs, after heating for a certain period of time, turn off the power, rely on the heat energy of fermentation organisms to maintain 70-90 degrees, and leave the tank after 12-24 hours;

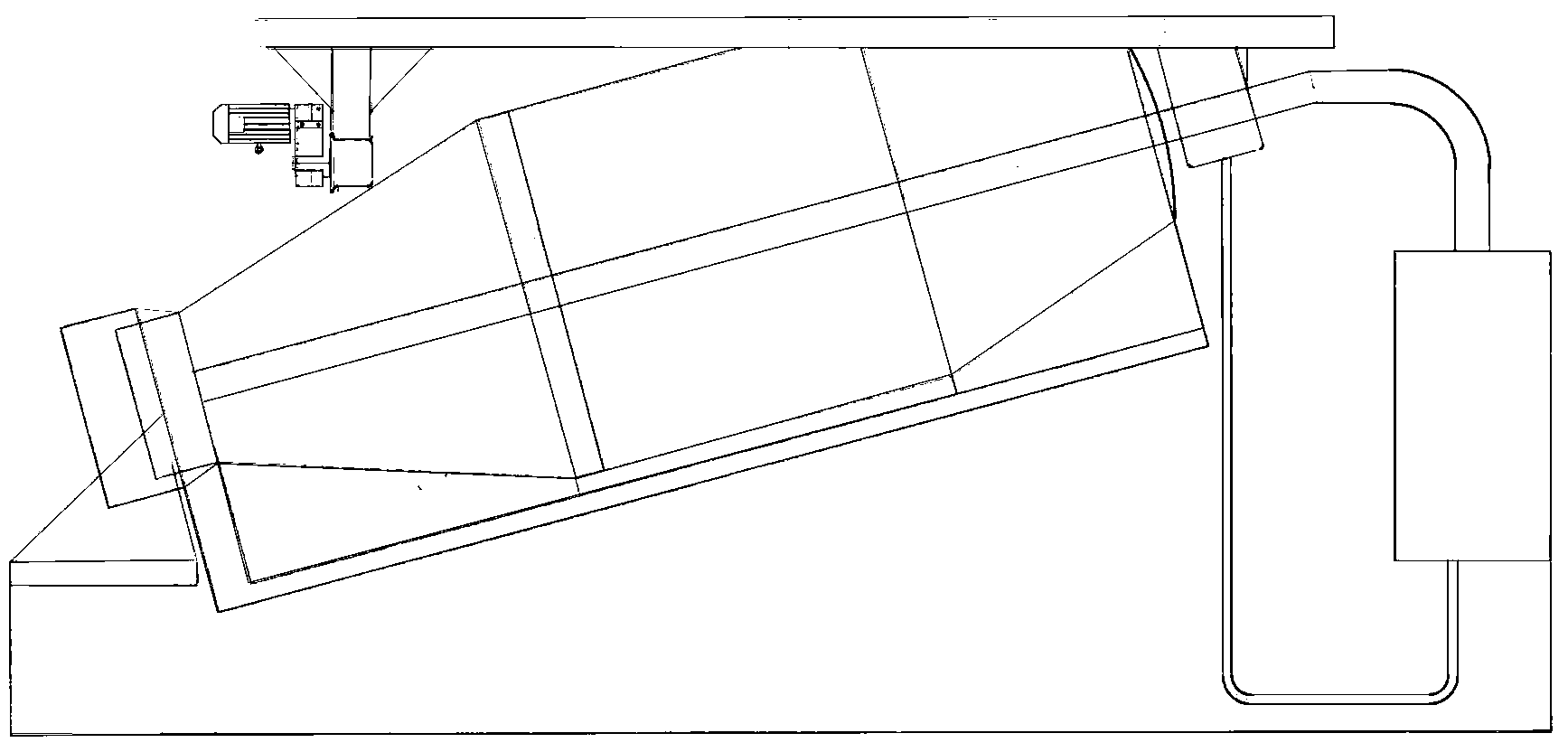

[0024] In the second stage, an air pump and an air pipeline are used for high-pressure aerated accumulation fermentation to further lose water and keep loose; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com