High strength injectable hydrogel and preparation method thereof

A hydrogel, high-strength technology, applied in the direction of non-active components of polymer compounds, medical science, prosthesis, etc., can solve the problems of low mechanical strength of hydrogel, achieve injectability, good biodegradability, The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

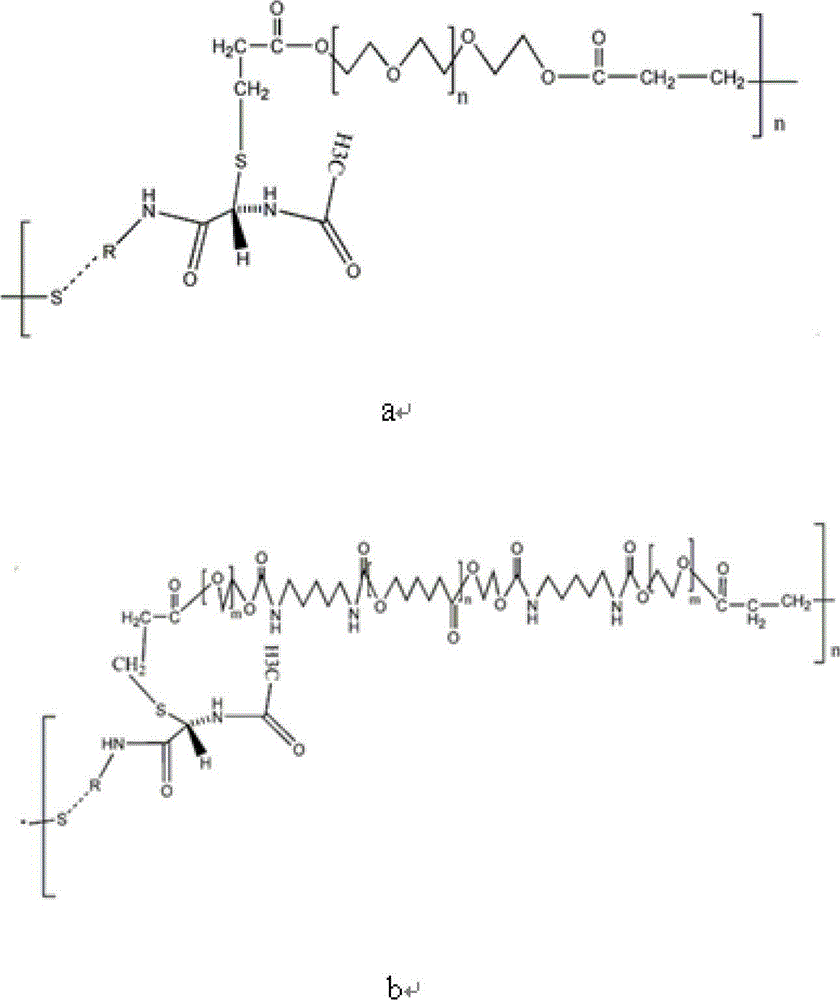

Method used

Image

Examples

Embodiment 1

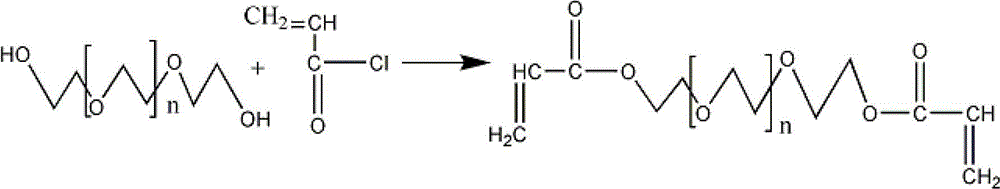

[0051] (1) Convert 5.0×10 -5 mol PEG (Mw=2000) was dissolved in 100mL of dichloromethane, cooled with ice water, added 0.01mol triethylamine and 0.025mol acryloyl chloride under the protection of nitrogen, and kept stirring. The temperature was raised to room temperature, and the reaction was carried out under nitrogen protection for 12 hours. The final reaction solution was filtered, precipitated, filtered under reduced pressure, and the final product was vacuum-dried at room temperature and collected for future use. This step yielded PEGDA2000.

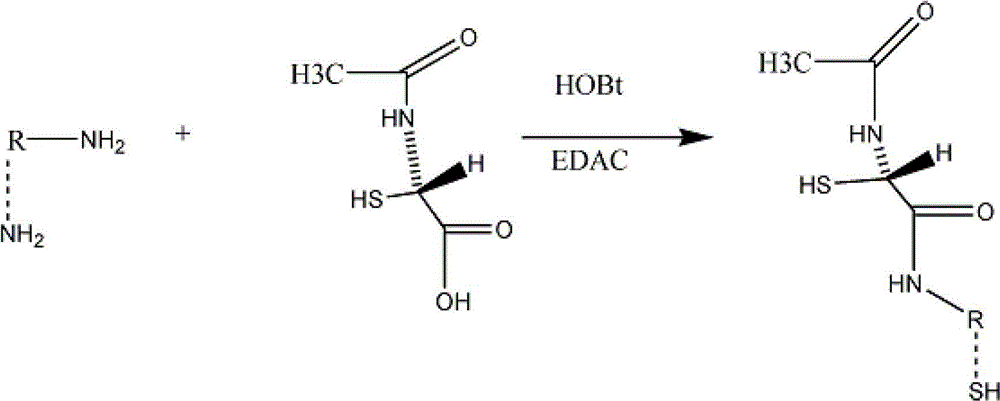

[0052] (2) Dissolve 1.00g of chitosan (Mn=30,0000) in 100ml of pure water, stir to form a suspension, add 697.2mg (5.16mmol) of HOBt, and stir until the solution is clear. Then add 3.368g (20.64mmol) of NAC, then add 7.914g (41.28mmol) of EDAC·HCL, pass nitrogen, avoid light, and adjust the pH to 5. After stirring and reacting at room temperature for 3 hours, it was dialyzed for three days at 4° C. in the dark, freeze-dried, and s...

Embodiment 2

[0058] (1) Convert 5.0×10 -5 mol PEG (Mw=2000) was dissolved in 100mL of dichloromethane, cooled with ice water, added 0.01mol of triethylamine and 0.02mol of acryloyl chloride under nitrogen protection, and kept stirring. The temperature was raised to room temperature, and the reaction was carried out under nitrogen protection for 12 hours. The final reaction solution was filtered, precipitated, filtered under reduced pressure, and the final product was vacuum-dried at room temperature and collected for future use. This step yielded PEGDA2000.

[0059] (2) Dissolve 1.00g of chitosan (Mn=30,0000) in 100ml of pure water, stir to form a suspension, add 2091.6mg (15.48mmol) of HOBt, and stir until the solution is clear. Then add 1.684g (10.32mmol) of NAC, then add 3.957g (20.64mmol) of EDAC·HCL, pass nitrogen, avoid light, and adjust the pH to 4. After stirring and reacting at room temperature for 5 hours, it was dialyzed for three days at 4° C. in the dark, freeze-dried, and s...

Embodiment 3

[0065] (1) Convert 5.0×10 -5 mol PEG (Mw=2000) was dissolved in 100mL of dichloromethane, cooled with ice water, added 0.02mol triethylamine and 0.025mol acryloyl chloride under the protection of nitrogen, and kept stirring. The temperature was raised to room temperature, and the reaction was carried out under nitrogen protection for 18 hours. The final reaction solution was filtered, precipitated, filtered under reduced pressure, and the final product was vacuum-dried at room temperature and collected for future use. This step yielded PEGDA2000.

[0066] (2) Dissolve 1.00g of chitosan (Mn=30,0000) in 100ml of pure water, stir to form a suspension, add 1045.8mg (7.74mmol) of HOBt, and stir until the solution is clear. Then add 3.368g (22.64mmol) of NAC, then add 7.914g (41.28mmol) of EDAC·HCL, pass nitrogen, avoid light, and adjust the pH to 5. After reacting with stirring at room temperature for 5 hours, it was dialyzed at 4°C in the dark for three days, freeze-dried, and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com