Low-temperature-resistant plastic packing tape and preparation method thereof

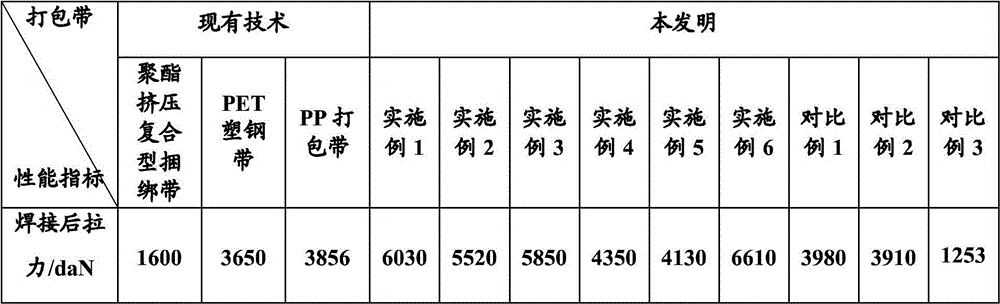

A technology of low temperature resistance and plastic, applied in packaging, transportation and packaging, flexible and slender components, etc., can solve the problems of not being able to pack heavy items and poor low temperature resistance of plastic packing belts, and achieve low cost, strong temperature resistance, and tensile strength powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a low-temperature-resistant packing tape that can be used in an environment around -50°C to -30°C. The low-temperature-resistant packing tape is prepared by the following steps:

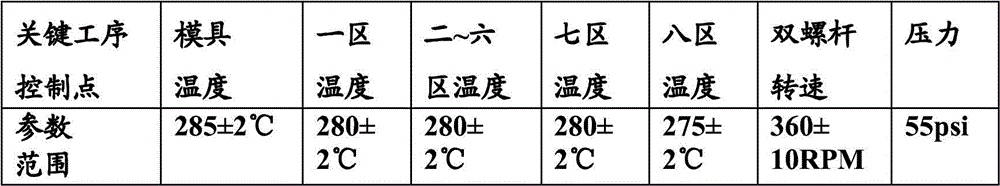

[0027] (1) Preparation of low-temperature-resistant polyester chips by screw blending: Dry 10kg PET, 20kg PBC and 1500g chain extender (GN5500) at 70°C for 4 hours and put them into a clean high-speed mixer, start the high-speed mixer, and stir for 5 Take it out after 10 minutes, and put it into the first section of the twin-screw extruder (the model is LTE-26-40), after melting and kneading, it will be pelletized underwater to obtain polyester chips, and screw extruded in the blending process The parameters of the machine are listed in Table 1.

[0028] Table 1

[0029]

[0030] (2), solid-phase thickening: put the polyester chips obtained in step (1) into a vacuum drum device, and the process control parameters are shown in Table 2.

[0031] Table 2

[0032] ...

Embodiment 2

[0035] This embodiment provides a low-temperature-resistant packing tape that can be used in an environment around -50°C to -30°C. The low-temperature-resistant packing tape is prepared by the following steps:

[0036] (1) Preparation of low-temperature-resistant polyester chips by screw blending: Dry 15kg PET, 15kg PBC and 1000g chain extender (GN5500) at 70°C for 4 hours and put them into a clean high-speed mixer, start the high-speed mixer, and stir for 5 Take it out after 10 minutes, and put it into the first section of the twin-screw extruder (the model is LTE-26-40), after melting and kneading, it will be pelletized underwater to obtain polyester chips, and screw extruded in the blending process The parameter of machine is with embodiment 1.

[0037] (2), solid-phase thickening: the polyester chips gained in step (1) are dropped into the drum device, and the process control parameters are basically the same as in Example 1. The difference is that the time for solid-phase...

Embodiment 3

[0040] This embodiment provides a low-temperature-resistant packing tape that can be used in an environment around -50°C to -30°C. The low-temperature-resistant packing tape is prepared by the following steps:

[0041] (1) Preparation of low-temperature-resistant polyester chips by screw blending: Dry 10kg PET, 20kg PBC and 1200g chain extender (GN5500) at 70°C for 4 hours and put them into a clean high-speed mixer, start the high-speed mixer, and stir for 5 Take it out after 10 minutes, and put it into the first section of the twin-screw extruder (the model is LTE-26-40), after melting and kneading, it will be pelletized underwater to obtain polyester chips, and screw extruded in the blending process The parameter of machine is with embodiment 1.

[0042] (2), solid-phase thickening: the polyester chips obtained in step (1) are dropped into a drum device, and the process control parameters are the same as in Example 1.

[0043] (3), making the polyester chips obtained in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com