System and method for preparing high-activity straw coke

A high activity, straw technology, used in coke ovens, special forms of dry distillation, petroleum industry, etc., can solve the problem of difficult to prepare reactive coke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

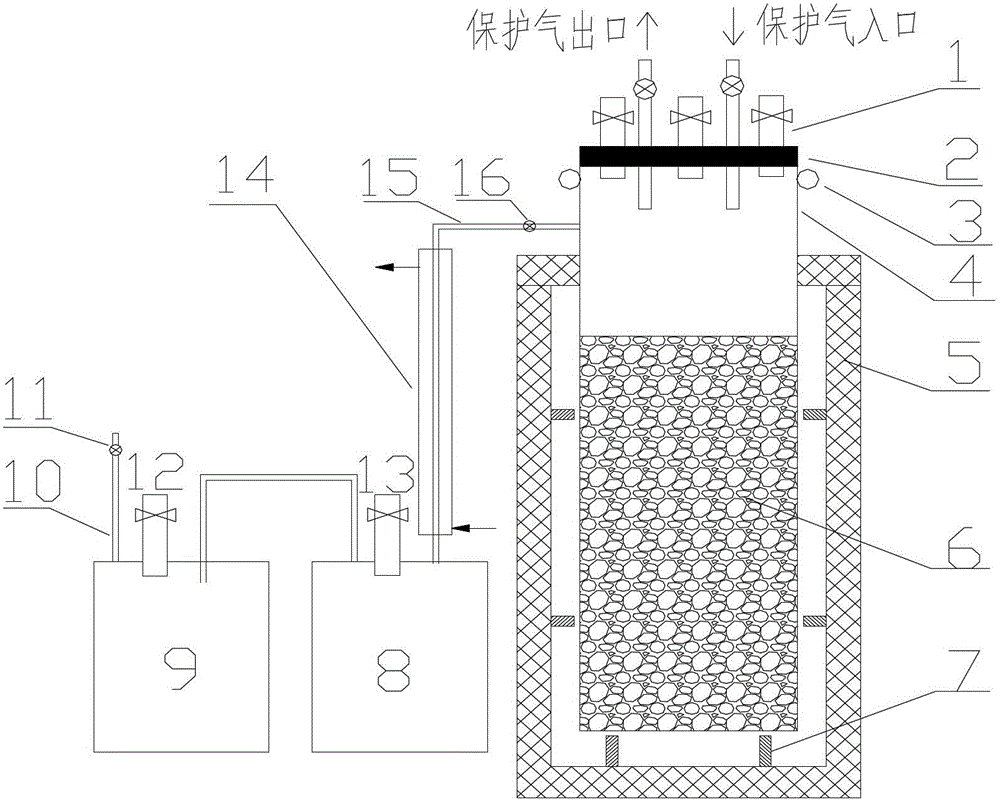

[0022] see figure 1 , the present invention includes a high-temperature heating furnace 5 internally provided with a supporting fixture 7, a coking reactor 4 is installed in the high-temperature heating furnace 5, and a protective gas inlet, a protective gas Exit and coking reactor explosion-proof door 1, coking reactor 4 is also equipped with a lifting hook 3, the upper end of the side wall of coking reactor 4 is provided with an outlet connected to the flue 15, and the flue 15 passes through the flue valve 16. The condenser 14 is in communication with the tar collection container 8, and the upper end of the tar collection container 8 is also communicated with the pyrolysis gas collection container 9 with the exhaust pipe 10 through a pipeline, wherein the tar collection container 8 is equipped with a tar collection container Container explosion-proof door 13; pyrolysis gas collection container explosion-proof door 12 is installed on the pyrolysis gas collection container 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com