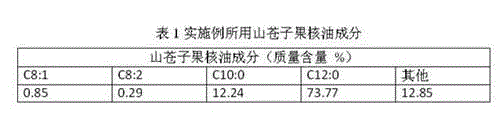

Method for preparing biological aviation fuel by using litsea cubeba kernel oil

A technology of aviation fuel and litsea cubeba oil, applied in the field of preparing bio-aviation fuel from litsea cubeba fruit seed oil, achieving good economic and social benefits and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment includes the following steps:

[0030] (1) Filter the litsea cubeba fruit pit oil to remove particulate impurities, add softened water at the same temperature at 70°C, the weight of the added softened water is equivalent to 5% of the weight of litsea cubeba oil, stir for 30 minutes, and then Centrifuge at a speed of 3000r / min for 30 minutes, take the supernatant, and dry it in a vacuum oven at 103°C for 3 hours to obtain refined litsea cubeba oil;

[0031] (2) After cooling the refined litsea cubeba fruit stone oil obtained in step (1), it is introduced into a fixed-bed hydrogenation reaction device filled with a hydrodeoxygenation catalyst to carry out a hydrodeoxygenation reaction; the hydrodeoxygenation catalyst is NiO- WO 3 / Aluminosilicate molecular sieve supported catalyst, the dosage is equivalent to 3% of the weight of the obtained refined Litsea cubeba oil, the temperature is raised to 350°C, the absolute pressure is 4MPa, and hydrogen is introd...

Embodiment 2

[0037] This embodiment includes the following steps:

[0038] (1) Filter the Litsea cubeba fruit kernel oil to remove particulate impurities, add softened water at the same temperature at 70°C, the weight of the added softened water is equivalent to 5% of the weight of Litsea cubeba oil, stir for 30 minutes, and then Centrifuge at a speed of 3000r / min for 30 minutes, take the supernatant, and dry it in a vacuum oven at 103°C for 3 hours to obtain refined litsea cubeba oil;

[0039] (2) After cooling the refined litsea cubeba fruit stone oil obtained in step (1), it is introduced into a fixed-bed hydrogenation reaction device filled with a hydrodeoxygenation catalyst to carry out a hydrodeoxygenation reaction; the hydrodeoxygenation catalyst is equivalent to the obtained Refined litsea cubeba oil weight 2% CoO-MoO 3 / γ-Al 2 o 3 Supported catalyst, the temperature is raised to 320°C, the absolute pressure is 3MPa, and hydrogen is introduced at the same time, the hydrogen-oil ...

Embodiment 3

[0043] This embodiment includes the following steps:

[0044] (1) Filter the Litsea cubeba fruit kernel oil to remove particulate impurities, add softened water at the same temperature at 70°C, the weight of the added softened water is equivalent to 5% of the weight of Litsea cubeba oil, stir for 30 minutes, and then Centrifuge at a speed of 3000r / min for 30 minutes, take the supernatant, and dry it in a vacuum oven at 103°C for 4 hours to obtain refined litsea cubeba oil;

[0045] (2) After cooling the refined litsea cubeba fruit stone oil obtained in step (1), it is introduced into a fixed-bed hydrogenation reaction device filled with a hydrodeoxygenation catalyst to carry out a hydrodeoxygenation reaction; the hydrodeoxygenation catalyst is equivalent to the obtained Refined litsea cubeba oil weight 5% NiO-MoO 3 / γ-Al 2 o 3 Supported catalyst, the temperature is raised to 350°C, the absolute pressure is 3.5MPa, and hydrogen is introduced at the same time, the volume rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com