Device and method for desulfurization by rotating inverted T-shaped spray gun

A technology of desulfurization device and spray gun, which is applied in the field of smelting technology, can solve the problems of poor kinetic conditions and achieve the effects of stabilizing the injection process, shortening the mixing time, and shortening the desulfurization treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

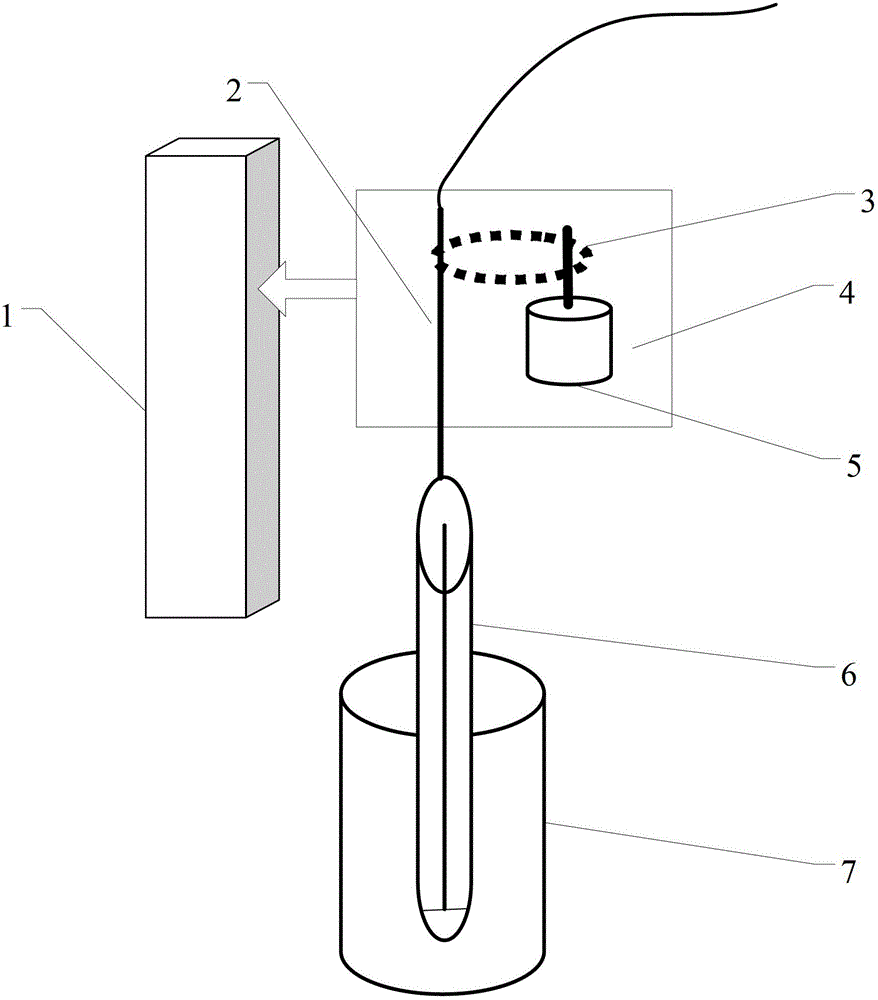

[0020] The specific desulfurization method and steps of the inverted T-shaped spray gun rotary desulfurization method are as follows:

[0021] 1. After the desulfurization control system calculates the injection data, start the injection operation.

[0022] The lifting mechanism on the support 1 drives the spray gun fixed frame 4 to descend, and the inverted T-shaped spray gun 6 fixed on the spray gun fixed frame 4 is vertically inserted into the molten iron in the molten iron tank 7, and the insertion depth is the distance between the lower end of the inverted T-shaped spray gun 6 and the molten iron. The bottom distance of tank 7 is 200mm.

[0023] 2. When the powder feeding rate in the inverted T-shaped spray gun 6 reaches the set value, the motor control system starts the rotating motor 5, and the rotating motor 5 drives the inverted T-shaped spray gun 6 to perform periodic reciprocating rotation in the forward and reverse directions through the chain 3. The rotational an...

Embodiment 2

[0026] The specific desulfurization method and steps of the inverted T-shaped spray gun rotary desulfurization method are as follows:

[0027] 1. After the desulfurization control system calculates the injection data, start the injection operation.

[0028] The lifting mechanism on the support 1 drives the spray gun fixed frame 4 to descend, and the inverted T-shaped spray gun 6 fixed on the spray gun fixed frame 4 is vertically inserted into the molten iron in the molten iron tank 7, and the insertion depth is the distance between the lower end of the inverted T-shaped spray gun 6 and the molten iron. The bottom distance of tank 7 is 220mm.

[0029] 2. When the powder feeding rate in the inverted T-shaped spray gun 6 reaches the set value, the motor control system starts the rotating motor 5, and the rotating motor 5 drives the inverted T-shaped spray gun 6 to perform periodic reciprocating rotation in the forward and reverse directions through the chain 3. The rotational an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com