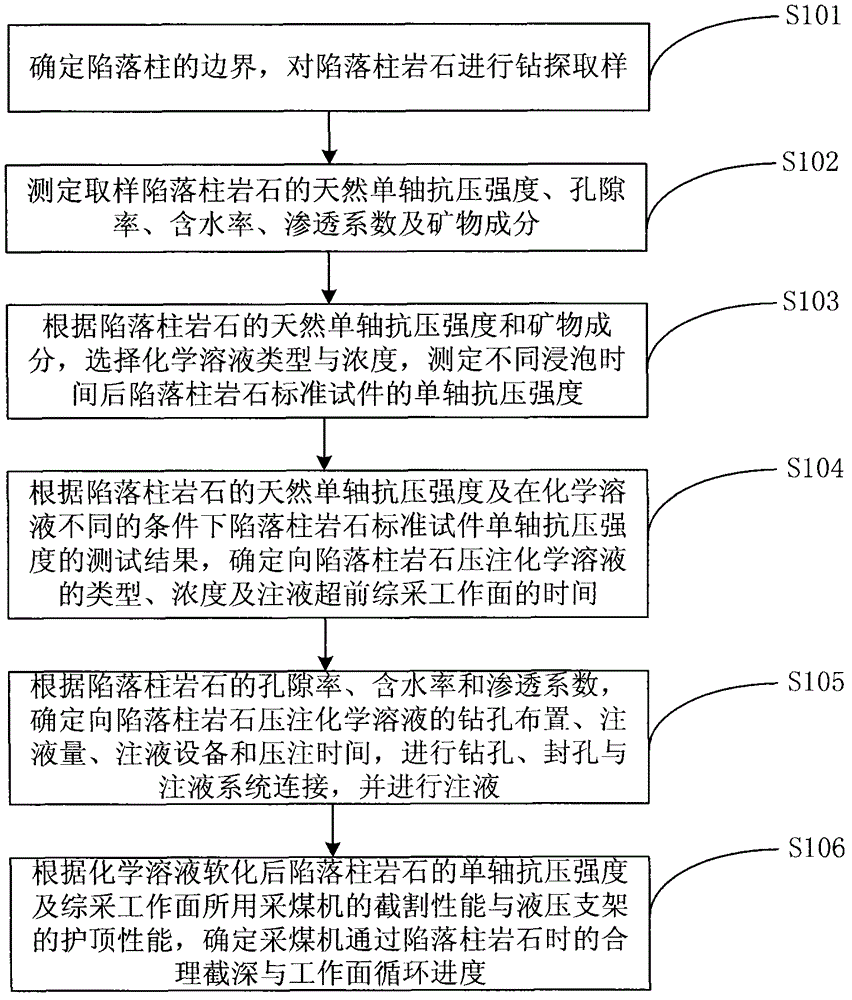

Method for chemically softening rock to allow fully mechanized coal face to pass collapsed column

A technology of fully mechanized mining face and chemical softening, applied in surface mining, earthwork drilling, underground mining, etc., can solve the problems of poor economy and practicability, large amount of engineering, low work efficiency, etc., and achieve strong promotion and application value. , to ensure normal advancement and eliminate the effect of bracket movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

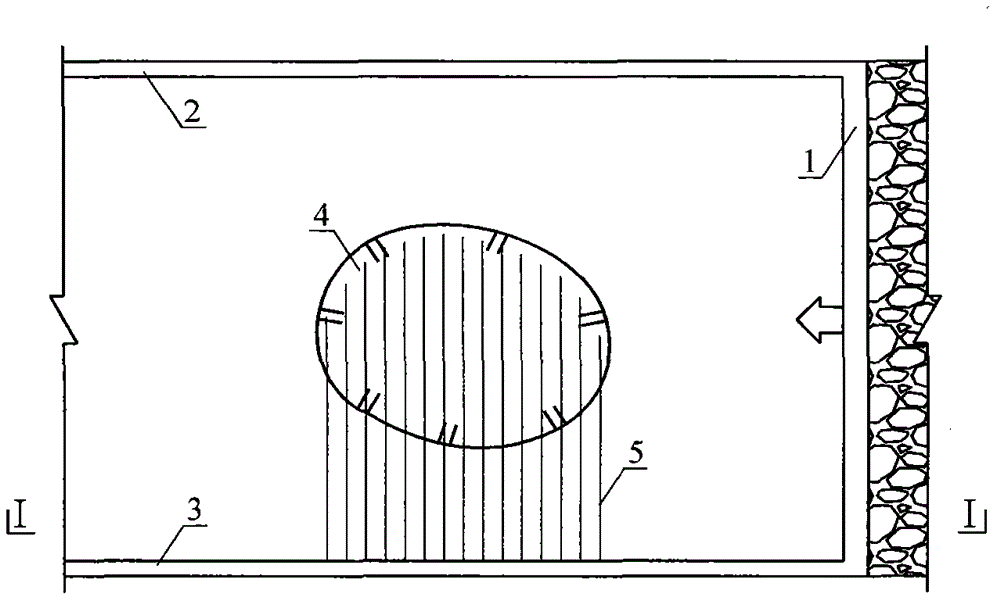

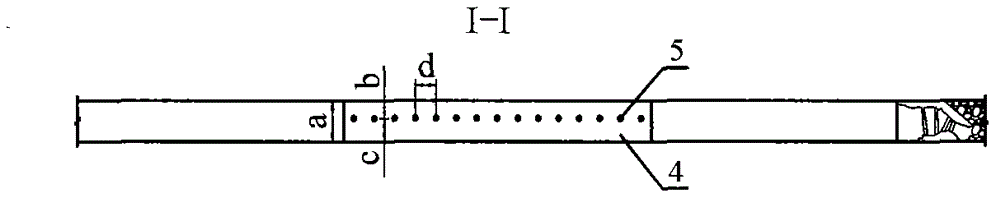

[0054] I. Reference figure 2 and image 3 , Through geophysical prospecting, it is determined that the shape of the subsidence column 4 of a certain mine is approximately elliptical, with a major axis of 94m and a short axis of 80m, and the shortest distance between the subsidence column 4 and the returning wind trough 3 is 42.5m;

[0055] II. Drilling and sampling the collapsed column rocks. According to rock mechanics test procedures, the natural uniaxial compressive strength of the collapsed column rocks is 46.61MPa, the porosity is 3.57%, the water content is 2.45%, and the permeability coefficient is 6×10 -3 cm / s, using X-ray diffractometer to determine the mineral composition of the collapsed pillar rock: 76% of quartz, 11% of muscovite, 4% of kaolinite, and 9% of pearl clay;

[0056] III. According to the natural compressive strength and mineral composition of the collapsed pillar rock measured in the above II, the mass fraction of the collapsed pillar rock sample is ...

Embodiment approach 2

[0061] I. Reference Figure 4 and Figure 5 , Through geophysical prospecting, it is determined that the shape of the subsidence column 4 of a mine 2 is approximately elliptical, with a major axis of 114.5m and a short axis of 75m.

[0062] II. Drilling and sampling the collapsed column rocks, according to the rock mechanics test regulations, the natural uniaxial compressive strength of the rocks is 53.86MPa, the porosity is 2.36%, the water content is 2.49%, and the permeability coefficient is 2×10 -3 cm / s, using X-ray diffractometer to determine the mineral composition of the collapsed pillar rock: 79% of quartz, 14% of muscovite, 5% of kaolinite, and 2% of pearl clay;

[0063] III. According to the natural compressive strength and mineral composition of the collapsed column rocks measured by the above II, the mass fraction of the rock samples is 0.1% CaCl 2 Solution immersion test, the uniaxial compressive strength test was carried out on the standard specimens of the col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability coefficient | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Uniaxial compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com