A waste tire crushing and desulfurization integrated device and application method based on supercritical carbon dioxide jet

A carbon dioxide, waste tire technology, applied in chemical instruments and methods, solid separation, chemical industry and other directions, can solve problems such as insufficient tendency to destroy cross-linked sulfur bonds, need to be improved, etc., to save processes, weaken mechanical strength, and reduce thresholds effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with specific embodiments, and the content of the present invention is not limited thereto at all.

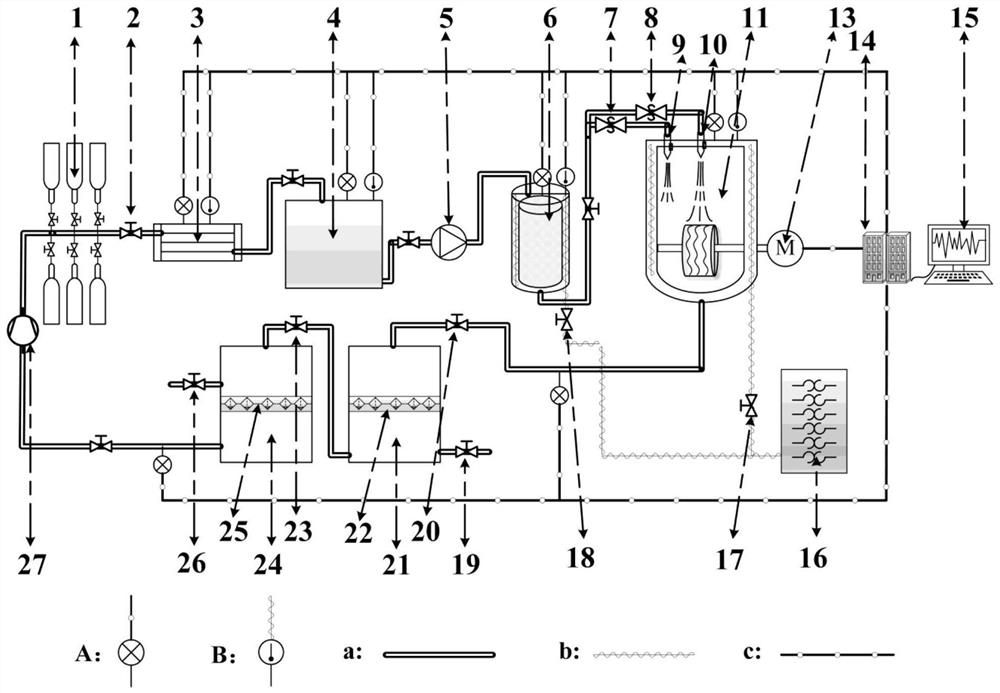

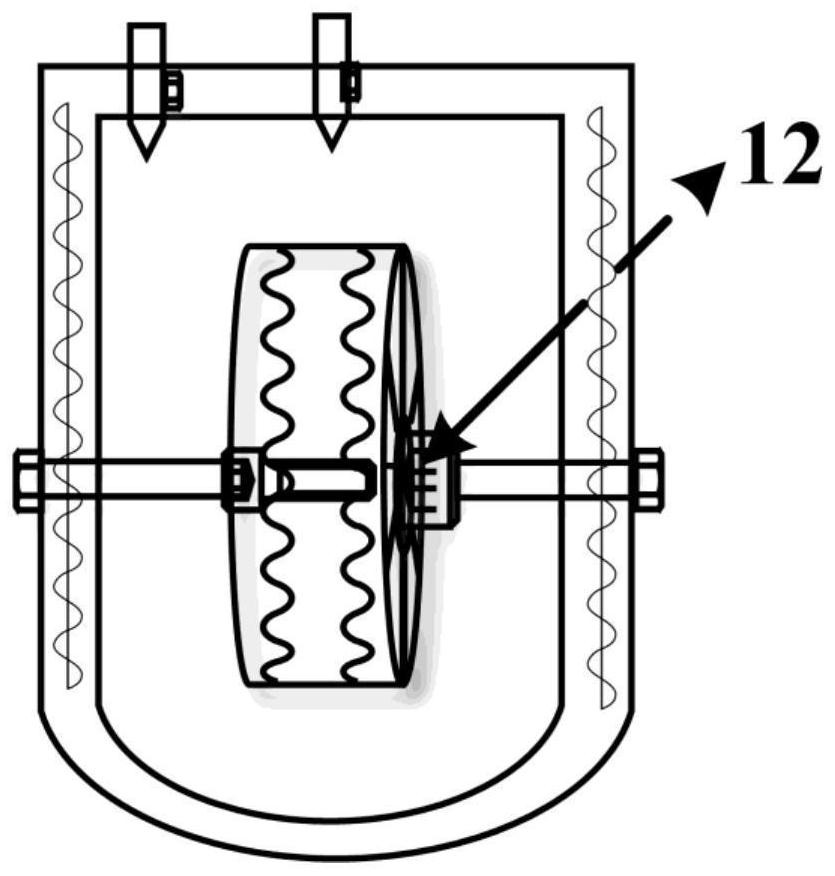

[0042] figure 1 The device structure and process flow chart of the present invention are shown.

[0043] An integrated waste tire crushing and desulfurization device based on a supercritical carbon dioxide jet, including a supercritical carbon dioxide input system, a tire crushing device, an oil bath heating system, a rubber powder recovery device and a control system.

[0044] 1. Supercritical carbon dioxide input system

[0045] The supercritical carbon dioxide input system includes a carbon dioxide gas cylinder 1 , a refrigeration device 3 , a liquid carbon dioxide storage tank 4 , a high-pressure plunger pump 5 and a carbon dioxide buffer tank 6 which are sequentially connected by pipelines.

[0046] A gas valve 2 is arranged between the carbon dioxide cylinder 1 and the refrigeration device 3 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com