Composite material backing water-lubricated rubber bearing and preparation method thereof

A technology of composite materials and rubber bearings, applied in the direction of sliding contact bearings, bearings, bearing components, etc., can solve the problems of difficulty in preparing large-size and high-precision water-lubricated bearings at the same time, and high product costs, and achieve easy processing, large size, and high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

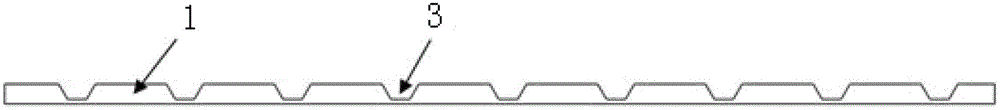

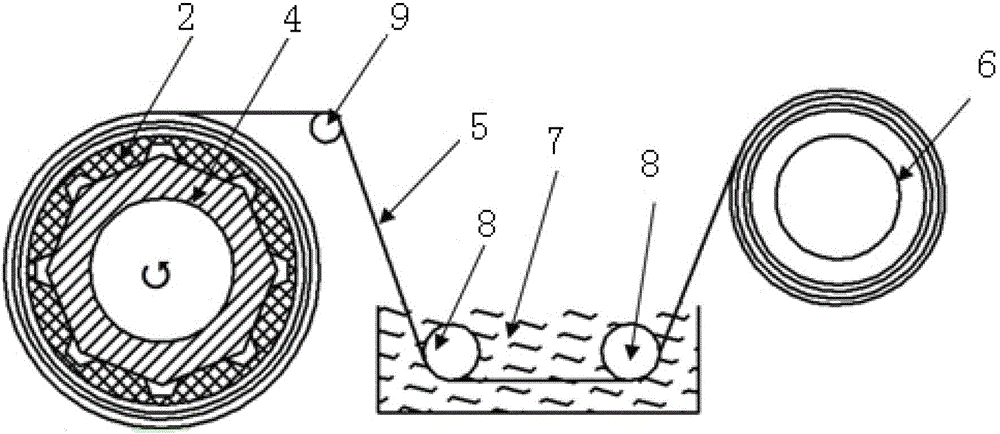

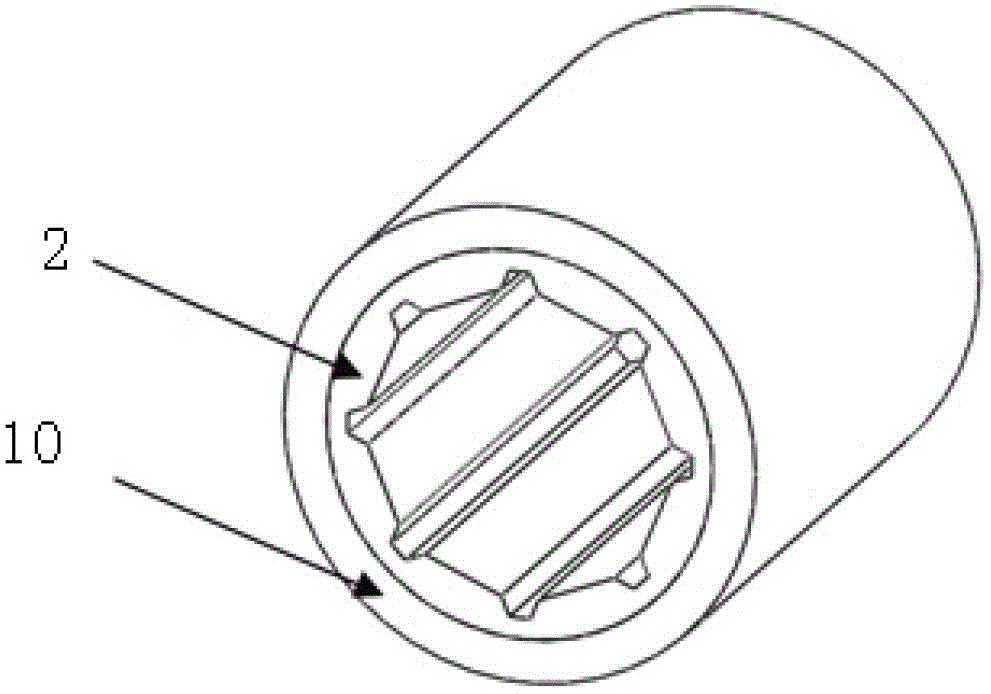

[0021] Put the styrene-butadiene rubber 1 into the mold and vulcanize the bearing surface layer 2, then wrap the bearing surface layer 2 around the polyhedral mold core 4 to form a cylinder, pass the glass fiber 5 on the wire wheel 6 through the dipping wheel 8, The epoxy resin 7 is completely infiltrated with the glass fiber 5, and the infiltrated glass fiber 5 is wound on the outer surface of the bearing surface layer 2 through the traction wheel 9 to form a composite material bearing jacket 10. When the thickness of the fiber layer reaches the required thickness, Stop the winding, cure the product at 60°C for 24 hours, take out the polyhedral mold core 4, and obtain the composite material-backed water-lubricated rubber bearing of the present invention. The resulting bearing dimensions are Inner diameter size error ± 0.15mm.

Embodiment 2

[0023] According to the method of Example 1, but using nitrile rubber instead of styrene-butadiene rubber to prepare the rubber surface layer, and then prepare the composite material backing water-lubricated rubber bearing of the present invention. The resulting bearing dimensions are Inner diameter size error ± 0.1mm.

Embodiment 3

[0025] According to the method of Example 1, but using polyurethane rubber instead of styrene-butadiene rubber to prepare the rubber surface layer, and then prepare the composite material-backed water-lubricated rubber bearing of the present invention. The resulting bearing dimensions are Inner diameter size error ± 0.2mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com