Coking industry-based gas dynamic balance scheduling method and system based on expert system

An expert system and dynamic balance technology, applied in the energy industry, climate sustainability, instruments, etc., can solve problems such as gas imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

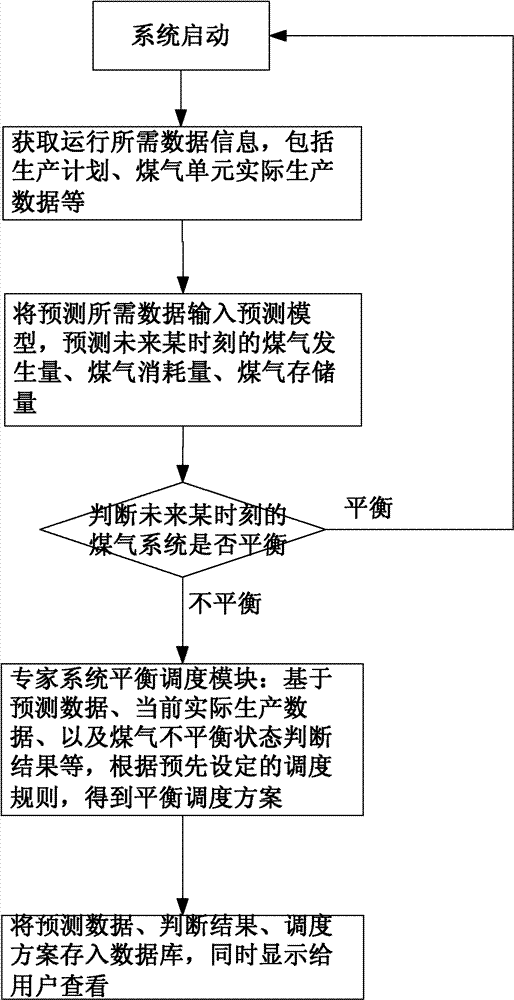

[0043] The gas dynamic balance scheduling system and method based on the expert system of the present invention adopt process mechanism modeling and regression analysis modeling to establish a gas-related unit prediction model to predict the gas generation, consumption and storage capacity of the gas system in the future, and based on this Based on the judgment of gas supply and demand balance, real-time and accurate provision of future gas system status for dispatchers. It should be noted that, for the determination of the future setting time, the method of time granularity can be used. The time granularity refers to the predicted time length, and the future time to be predicted can be determined according to the model startup time and time granularity; of course, it is also possible to Use other methods to determine the set moment in the future, such as artificially preset a certain point in the future.

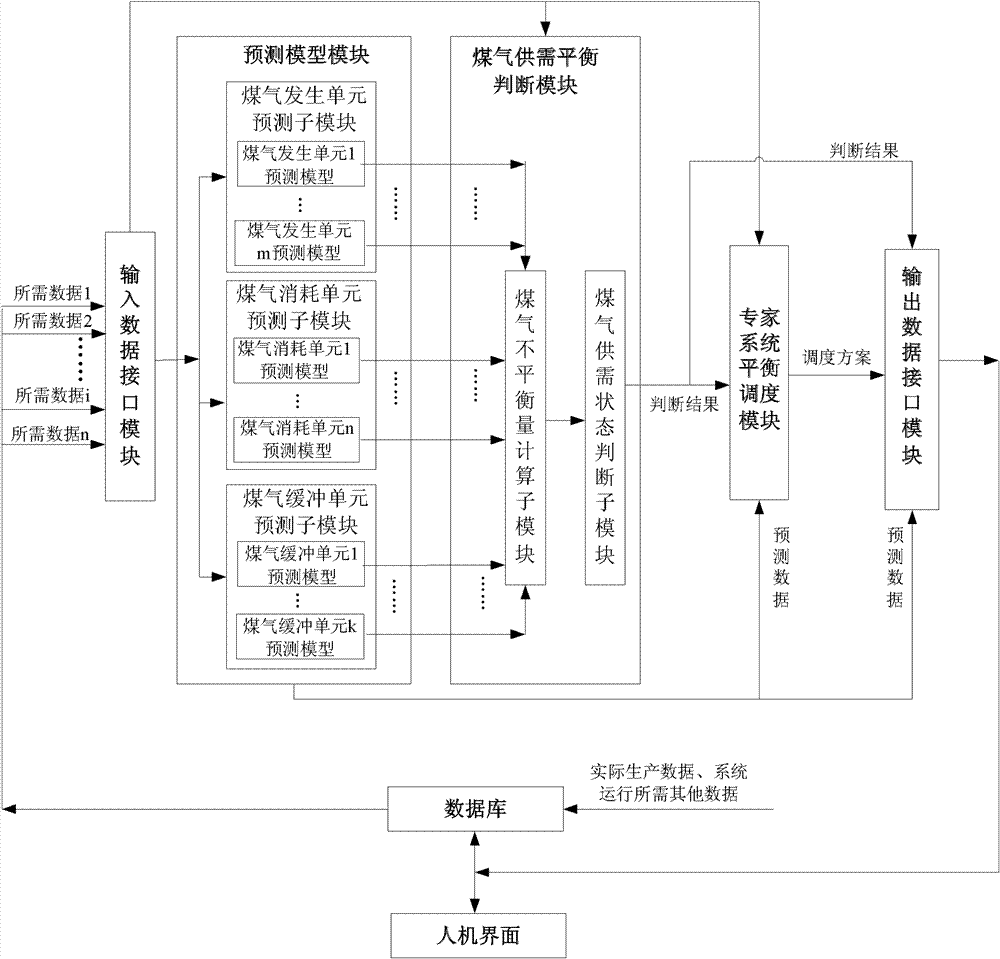

[0044] Figure 1a It is the structural diagram of the gas dynamic bala...

Embodiment 2

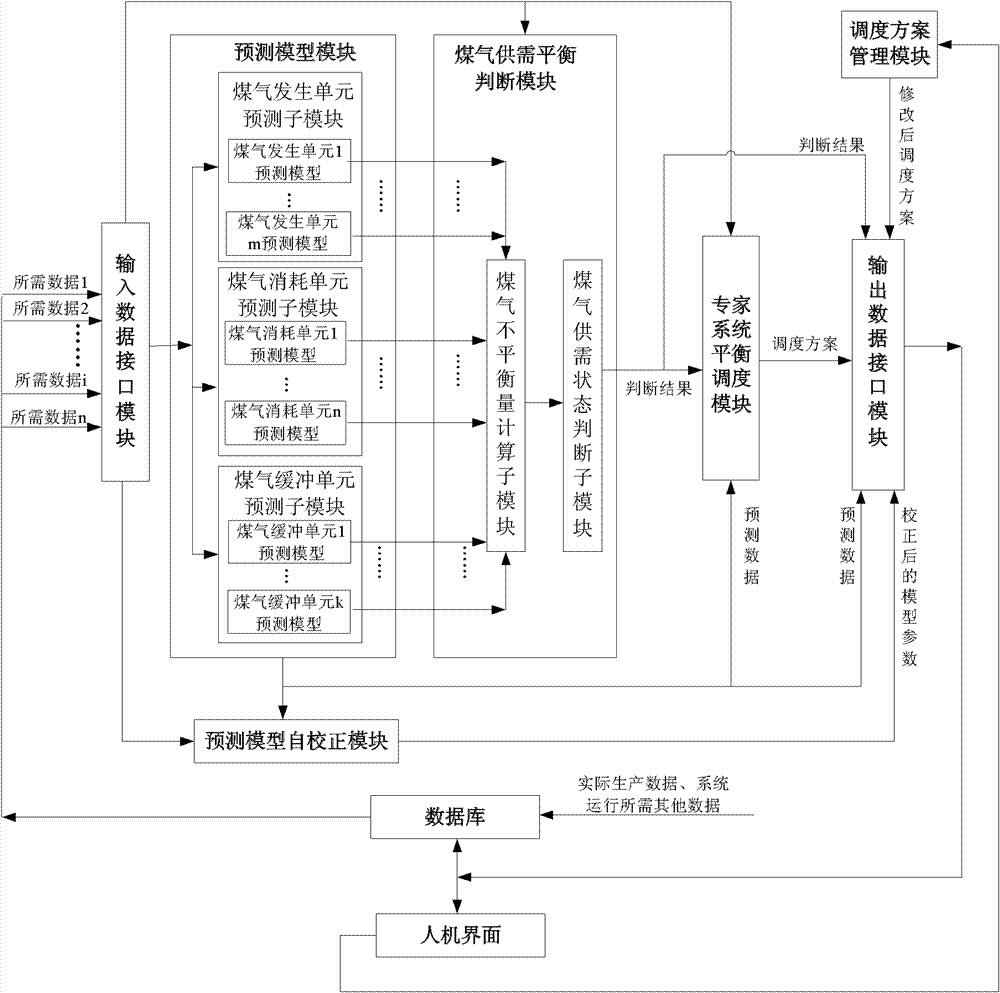

[0064] Example 2 as Figure 1b with Figure 2b Shown, is to carry out perfection and improvement on the basis of embodiment 1. Only the differences between Embodiment 2 and Embodiment 1 will be described in detail below.

[0065] The gas dynamic balance scheduling system based on the expert system of embodiment 2, on the basis of embodiment 1, also includes the prediction model self-calibration module, and the prediction model self-correction module receives from each gas unit prediction sub-module of the prediction model module Prediction data, online monitoring and real-time calculation of the deviation between the actual production data of the production feedback at the set time and the corresponding forecast data, and comparing the deviation with the preset threshold; if the absolute value of the deviation is greater than the threshold, then according to the actual The production data is recalculated and the corresponding model parameters in the forecast model module are u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com