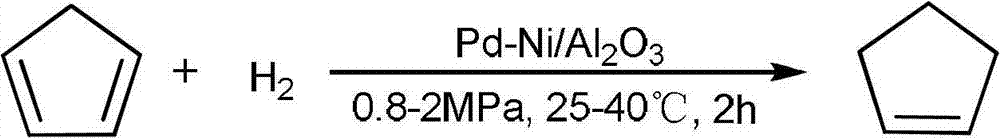

Pd-Ni/Al2O3 catalyst, its preparation method and application thereof

A technology of catalysts and catalyst carriers, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem that the conversion rate of cyclopentadiene is only 86% , to achieve good reusability, mild reaction conditions, and improved selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Non-limiting embodiments of the present invention are described as follows:

[0025] 1. Preparation of catalyst

[0026] PdCl 2 and Ni(NO 3 ) 2 Add to the acetic acid solution with a mass concentration of 30%, the mass ratio of Pd and Ni is 1:0.5-3, stir to dissolve and then add Al 2 o 3 H2O, stir evenly and let stand for 2h, then dry at 100-120°C for 8-10h, and then roast at 540-560°C for 2.5-3.5h, after roasting, pass in hydrogen to activate the catalyst, so that Ni oxide can be reduced to Active Ni, the activation temperature is 250°C, the pressure is 0.1MPa, the hydrogen flow rate is 45ml / min, and the activation time is 48 hours, that is, Pd-Ni / Al can be produced 2 o 3 Catalyst, where PdCl 2 and Ni(NO 3 ) 2 The total mass of Al 2 o 3 ·H 2 0.5-1% of O mass;

[0027] 2. Liquid phase catalytic hydrogenation

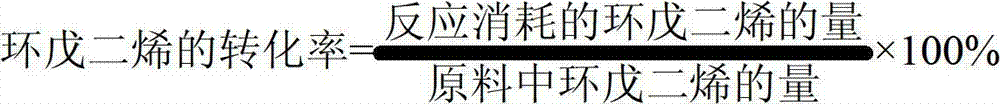

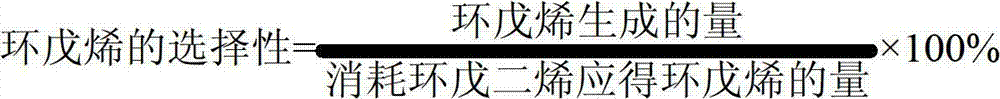

[0028] The Pd-Ni / Al prepared in step 1 2 o 3 Catalyst and 50g of cyclopentadiene (derived from dicyclopentadiene cracking, dicyclopentadiene conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com