Self-activation flotation method for component of fluid inclusion of copper sulfide ore

A technology of fluid inclusions and copper sulfide ore, which is applied in flotation, solid separation, etc., to achieve the effects of reducing the amount of collectors, reducing flotation costs, and improving recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

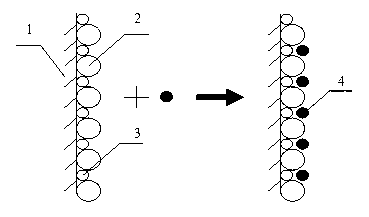

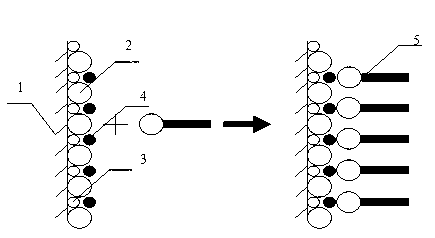

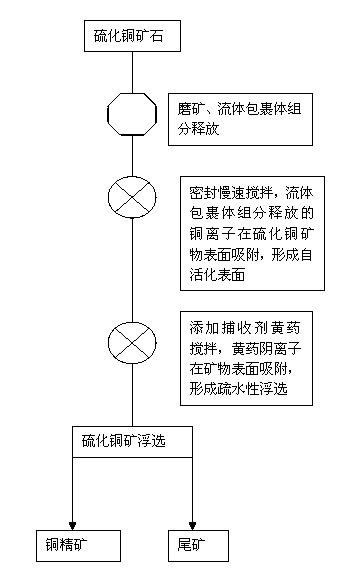

Method used

Image

Examples

Embodiment 1

[0024] Copper sulfide ore has a copper grade of 0.70% and an oxidation rate of 8%. The copper sulfide mineral is chalcopyrite, and the copper oxide mineral is malachite. The type of ore is hydrothermal, with abundant fluid inclusions.

[0025] (1) The ore is ground at a concentration of 80~85wt% until the dissociation degree of the copper sulfide mineral monomer is greater than 80%, the grinding fineness is -200 mesh, and the content reaches 88%. The copper in the fluid inclusion of the copper sulfide mineral The ions are released into the slurry solution, and at the same time the newly formed surface of the copper sulfide mineral relaxes, forming a "sulfur-rich" surface.

[0026] (2) Dilute the copper sulfide ore grinding slurry obtained in step (1) with water to a concentration of 30wt%, add 60g / t ammonium chloride, and put it into the first sealed mixing tank at a slow speed of 0.5-1m / s Stir quickly to make the copper ions released from the fluid inclusion and the added copper i...

Embodiment 2

[0030] Copper sulfide ore has a copper grade of 0.90% and an oxidation rate of 10%. The copper sulfide mineral is mainly chalcopyrite, followed by chalcocite. The copper oxide mineral is malachite, the ore type is hydrothermal, and fluid inclusions are abundant.

[0031] (1) The ore is ground at a concentration of 80~85wt% until the dissociation degree of the copper sulfide mineral monomer is greater than 80%, the grinding fineness is -200 mesh, and the content reaches 90%. The copper in the fluid inclusion of the copper sulfide mineral The ions are released into the slurry solution, and at the same time the newly formed surface of the copper sulfide mineral relaxes, forming a "sulfur-rich" surface.

[0032] (2) Dilute the copper sulfide ore grinding slurry obtained in step (1) with water to a concentration of 35wt%, add 70g / t ammonium chloride, and put it into the first sealed mixing tank at a slow speed of 0.5-1m / s Stir quickly to make the copper ions released from the fluid incl...

Embodiment 3

[0036] Copper sulfide ore contains copper grade 1.10%, oxidation rate is 12%, copper sulfide mineral is mainly chalcopyrite, followed by bornite, copper oxide mineral is malachite, ore type is hydrothermal metamorphism, with fluid inclusions , But the quantity is less than the hydrothermal type.

[0037] (1) The ore is ground at a concentration of 80~85wt% until the dissociation degree of the copper sulfide mineral monomer is greater than 80%, the grinding fineness is -200 mesh, and the content reaches 85%. The copper in the fluid inclusion of the copper sulfide mineral The ions are released into the slurry solution, and at the same time the newly formed surface of the copper sulfide mineral relaxes, forming a "sulfur-rich" surface.

[0038] (2) Dilute the copper sulfide ore grinding slurry obtained in step (1) with water to a concentration of 40wt%, add copper sulfate 5 (or 8, or 10) g / t, add 100g / t ammonium chloride, and put it in the first A sealed mixing barrel, stirring slowl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com