Cutter shaft control method of leading line yielding track in blade helical milling process

A technology of blade helix and control method, used in milling machine equipment, manufacturing tools, details of milling machine equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Describe the present invention below in conjunction with specific embodiment:

[0049] In this embodiment, the five-axis annular cutter machining of a blade of a certain type of aeroengine is taken as an example, and the trajectory of the cutter position point in the curved surface area of the blade body is calculated according to the second-order Taylor approximation algorithm, wherein the radius R of the annular cutter is 8 mm.

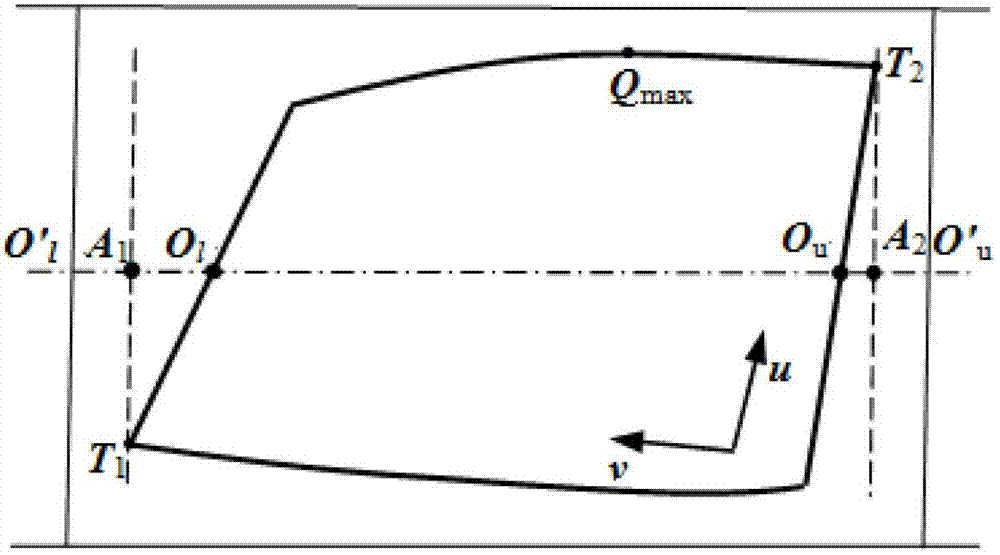

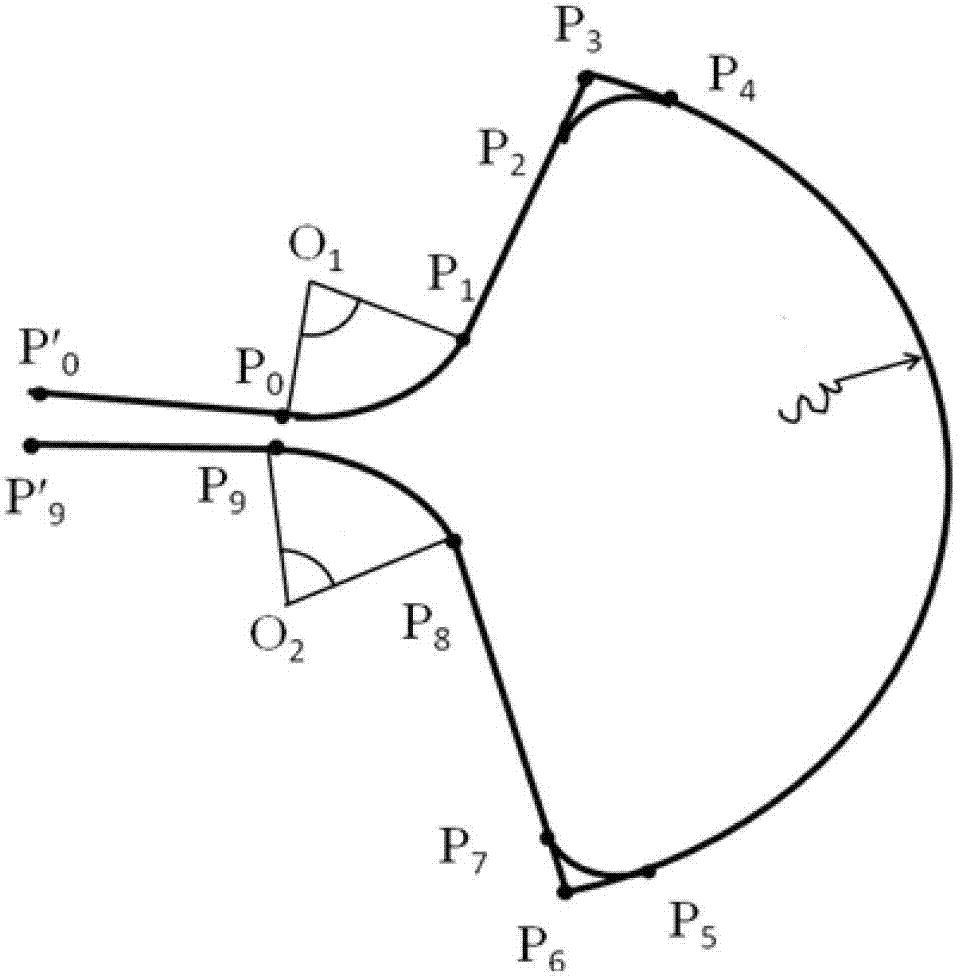

[0050] In this embodiment, the tool axis control method of the edge avoidance track includes the following steps:

[0051] Step 1: Construct the cylindrical auxiliary surface of the blade:

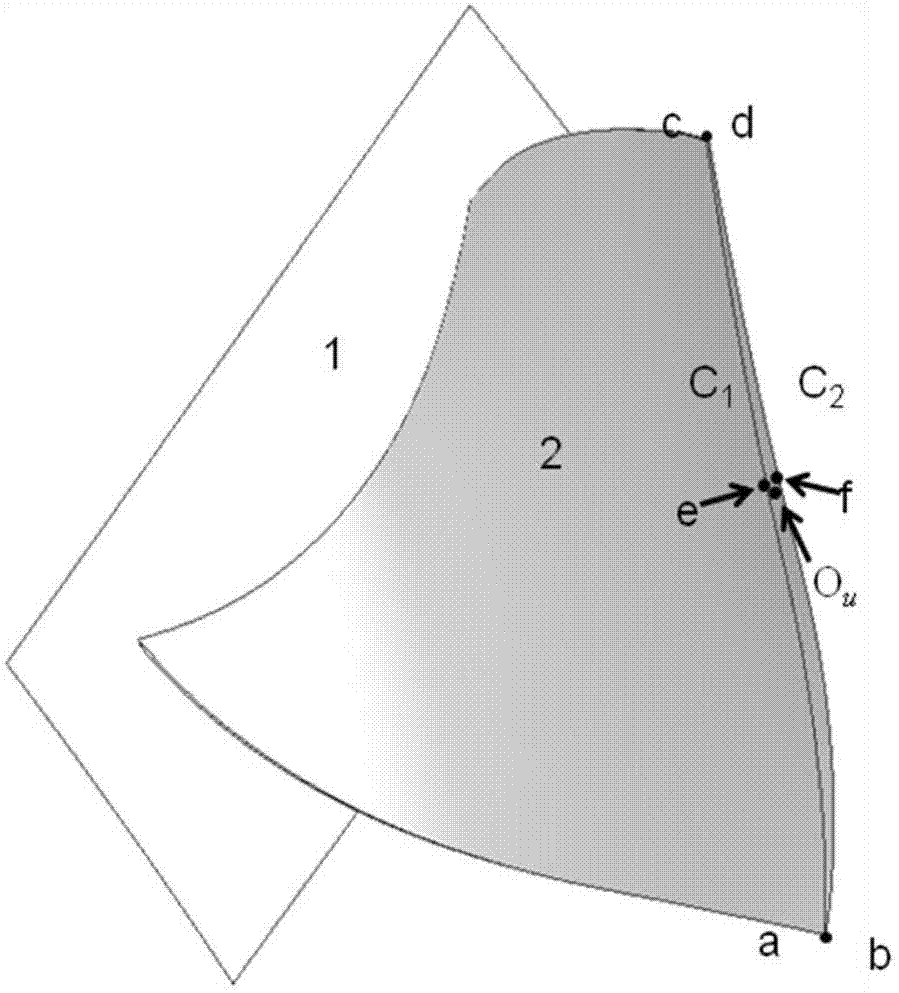

[0052] The auxiliary surface of the blade containing cylinder is a tool to realize the avoidance curve of the edge head. The key to determine the cylindrical surface is the center of the top circle, the center of the bottom circle and the radius of the cylinder. figure 1 shown. The curved surface of the blade body (the curved surface of the blade basi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com