Method for connecting yoke and shaft

A connection method and connection method technology, which are applied to mechanical steering gears, steering mechanisms, steering rods, etc., can solve the problems of complicated manufacturing of the lower fork and transmission shaft, slipping failure of the automobile steering system, and incomplete transmission of steering power, etc. The effect of reducing machining cost, not easy to slip, and reducing machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

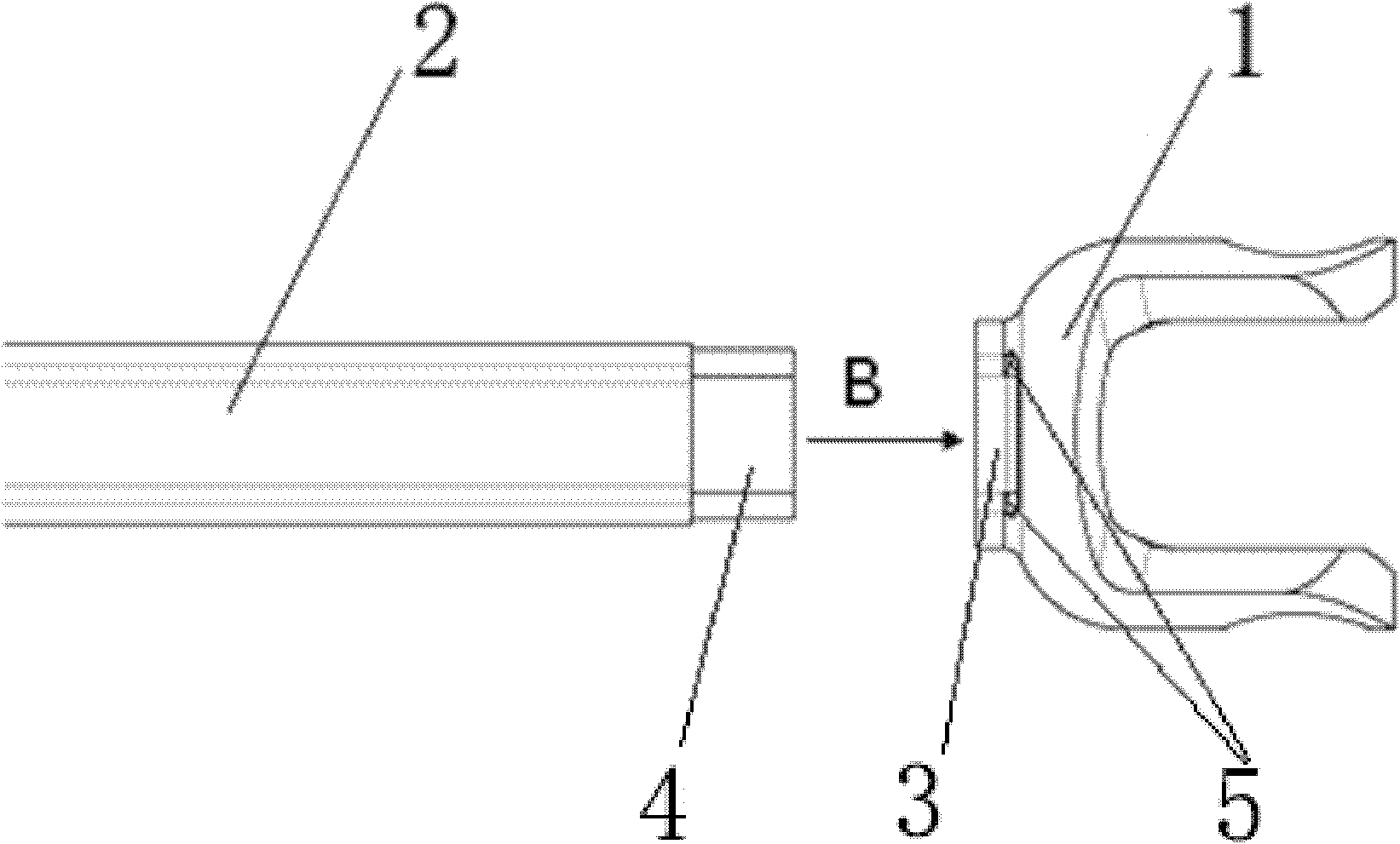

[0042] Such as Figure 7 to Figure 8 As shown, a method for connecting a yoke and a shaft of the present invention, the remaining steps are as in Embodiment 1, but a fixed riveting point 6 is set at the connection between the transmission end 4 and the waist-shaped inner hole 3. In this embodiment, a 4 riveting points, compared with welding connection, riveting connection has lower processing requirements, and is suitable for low-cost steering column connection.

[0043] A method for connecting a yoke and a shaft of the present invention has a simple structure, changes the relatively complex yoke processing technology in the prior art, and reduces the machining cost by 10% to 15% compared with the original design, and has obvious advantages. It has the effect of reducing the cost of the overall steering column, and can effectively transmit torque, is not easy to slip, has better transmission effect, can meet the effect of safe transmission, and improves the safety of the whole...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap