Anti-channel conflict code-spurting printing ink and its preparation method

A technology for printing ink and coding, applied in ink, household appliances, applications, etc., can solve the problems of limited printing position, ink printing, increase production cost, etc., to reduce production cost and prevent smuggling of goods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

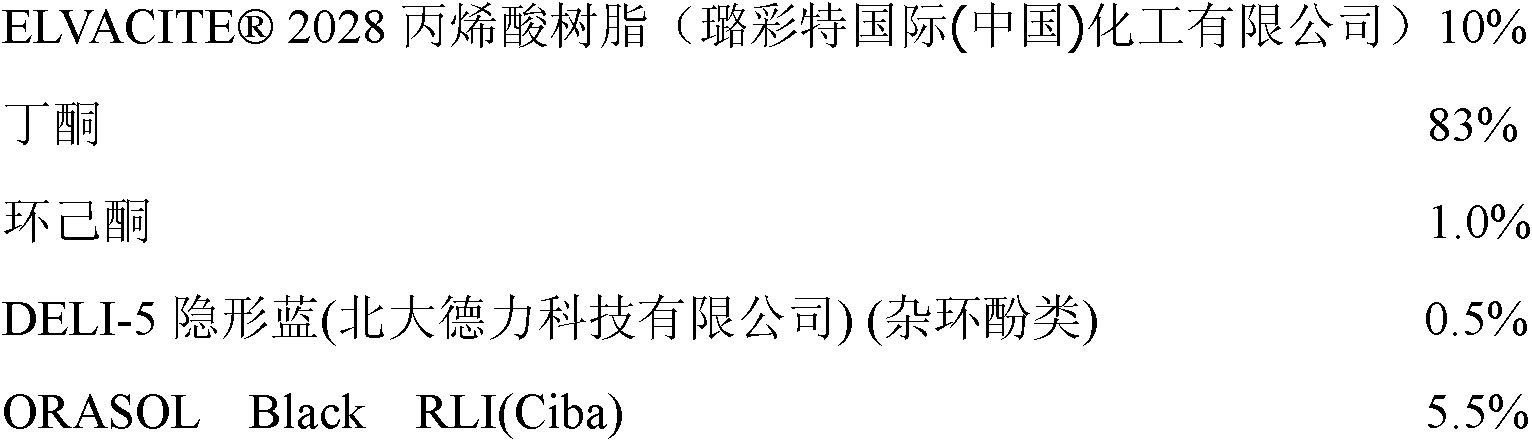

[0039] This embodiment provides an anti-smuggling inkjet printing ink, which has the following raw materials, and the total weight of the inkjet printing ink is 100%:

[0040]

[0041] The anti-smuggling inkjet printing ink provided in this embodiment can be prepared through the following steps:

[0042] At first polymer resin ( 2028) dissolve;

[0043] After the polymer resin is completely dissolved, dissolve and disperse the colorless organic fluorescent dye (DELI-5) according to the raw material composition of the ink;

[0044] After the colorless organic fluorescent dye is completely dissolved, dissolve the organic solvent soluble dye (ORASOL Black RLI);

[0045] After the organic solvent-soluble dye is completely dissolved, the viscosity test is carried out, and then the remaining organic solvent is replenished to obtain the anti-smuggling printing ink.

[0046] Viscosity test and viscosity adjustment of the prepared inkjet printing ink were performed, followed by ...

Embodiment 2

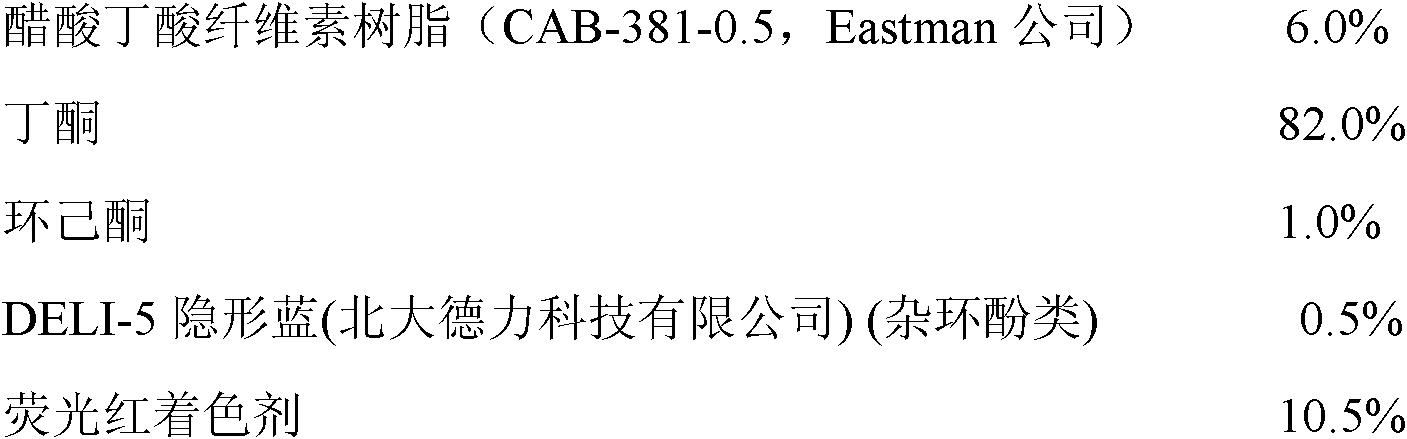

[0049] This embodiment provides an anti-smuggling inkjet printing ink, which has the following raw materials, and the total weight of the inkjet printing ink is 100%:

[0050]

[0051] Preparation process and parameter test Referring to Example 1, the specific parameters of the ink prepared in this example are as follows: viscosity: 3.8CP / 25°C, electrical conductivity: 1600μS, surface tension: 33.5dyn / cm (20°C).

Embodiment 3

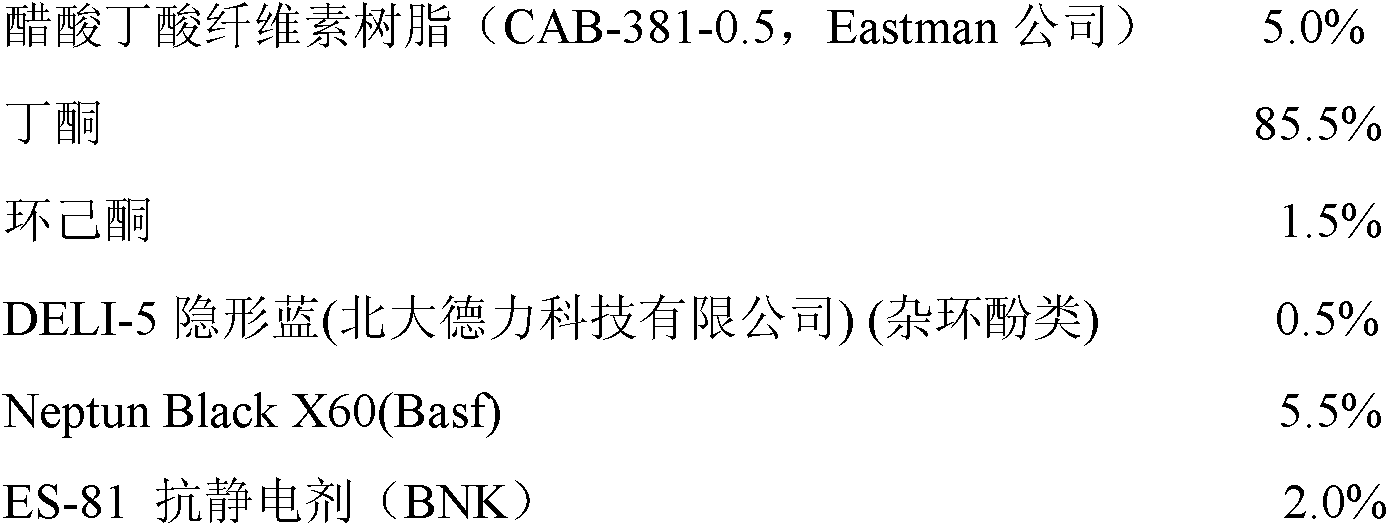

[0053] This embodiment provides an anti-smuggling inkjet printing ink, which has the following raw materials, and the total weight of the inkjet printing ink is 100%:

[0054]

[0055] The preparation steps and parameter tests are the same as in Example 1. The specific parameters of the ink prepared in this example are as follows: viscosity: 3.8CP / 25°C, electrical conductivity: 760μS, surface tension: 33.5dyn / cm (20°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com