Vegetable oil-based adhesive, composite plywood and method for manufacturing composite plywood

A vegetable oil-based, adhesive technology, applied in adhesives, oil/fat/wax adhesives, non-polymer organic compound adhesives, etc., can solve the problems of difficult recycling and resins that cannot be melt-processed, and save economic costs , good social and economic effects, and the effect of reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

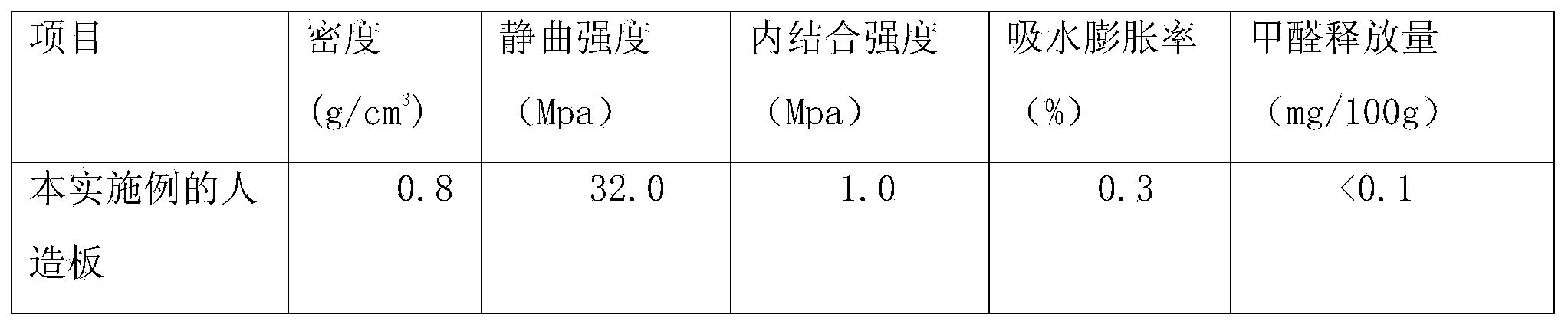

Embodiment 1

[0026] For the vegetable oil-based adhesive of this embodiment, the raw materials of the adhesive include the following components by weight: 100 parts of vegetable oil-based resin, 250 parts of active resin, 150 parts of curing agent, 10 parts of catalyst, and 200 parts of additives.

[0027] The method of utilizing the vegetable oil-based adhesive of the present embodiment to manufacture a composite wood-based panel comprises the following steps:

[0028] a. crushing 3000 parts by weight of petrochemical resin into particles with a particle diameter of 1 mm, and uniformly mixing with 3000 parts by weight of fibers to obtain fillers;

[0029] b. uniformly mixing the vegetable oil-based resin, the active resin, the curing agent, the catalyst and the additive according to the set weight parts to prepare the adhesive glue;

[0030] c. Spray the adhesive glue that accounts for 30% of the total amount of filler in step a on the filler in step b, and mix evenly to obtain a wood-bas...

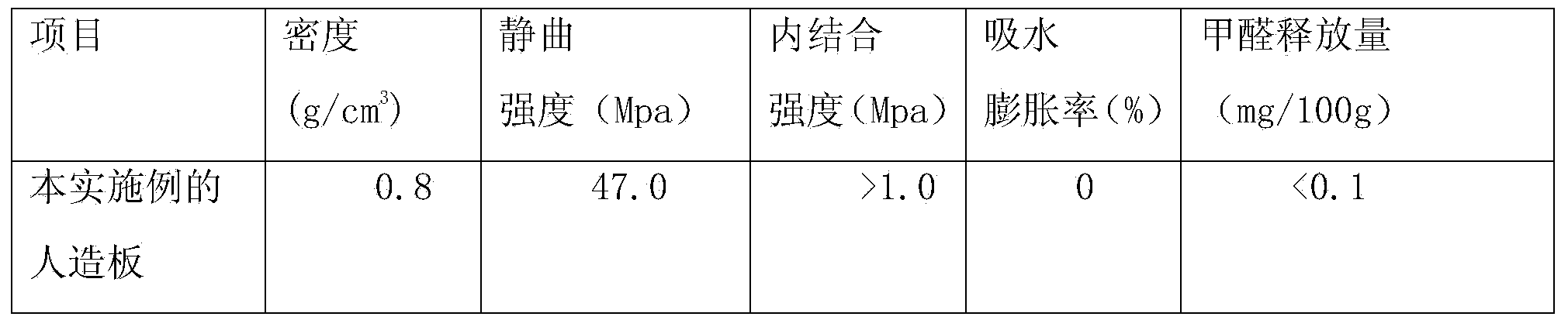

Embodiment 2

[0041] For the vegetable oil-based adhesive of this embodiment, the adhesive raw materials include the following components by weight: 120 parts of vegetable oil-based resin, 500 parts of active resin, 300 parts of curing agent, 50 parts of catalyst, and 400 parts of additives.

[0042] The method of utilizing the vegetable oil-based adhesive of the present embodiment to manufacture a composite wood-based panel comprises the following steps:

[0043] a. crushing 6000 parts by weight of petrochemical resin into particles with a particle diameter of 10 mm, and uniformly mixing with 6000 parts by weight of fibers to obtain fillers;

[0044] b. uniformly mixing the vegetable oil-based resin, the active resin, the curing agent, the catalyst and the additive according to the set weight parts to prepare the adhesive glue;

[0045] c. Spray the adhesive glue that accounts for 60% of the total amount of filler in step a on the filler in step b, and mix evenly to obtain a wood-based pan...

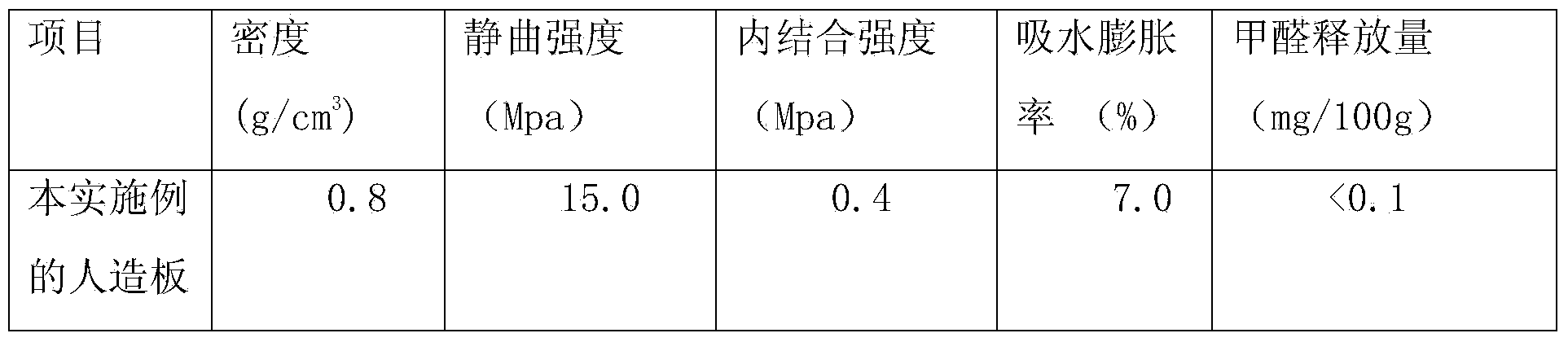

Embodiment 3

[0057] For the vegetable oil-based adhesive of this embodiment, the raw materials of the adhesive include the following components by weight: 80 parts of vegetable oil-based resin, 200 parts of curing agent, 10 parts of catalyst, and 200 parts of additives.

[0058] The method of utilizing the vegetable oil-based adhesive of the present embodiment to manufacture a composite wood-based panel comprises the following steps:

[0059] a. crushing 20 parts by weight of petrochemical resin into particles with a particle diameter of 0.01 mm, and uniformly mixing with 3000 parts by weight of fibers to obtain a filler;

[0060] b. uniformly mixing the vegetable oil-based resin, curing agent, catalyst and additives according to the set weight parts to prepare the adhesive glue;

[0061] c. Spray the adhesive liquid that accounts for 2% of the total amount of filler in step a on the filler in step b, and mix evenly to obtain a wood-based panel composite;

[0062] d. Lay the wood-based pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com