Finishing technology of nano-grade phase-change microcapsule heat-accumulation temperature-adjustment intelligent textile fabric printed cloth

A technology of microcapsule finishing, heat storage and temperature regulation, applied in microcapsule preparations, textiles and papermaking, microsphere preparation, etc., can solve the problems of small volume expansion rate and residual formaldehyde, and achieve slow heating or cooling rate and good effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0046] Cotton printing and dyeing cloth: weave specifications: 18.2tex / 18.2tex+40D, 738 threads / 10cm, 315 threads / 10cm.

[0047] Paraffin phase change material (A): n-eicosane.

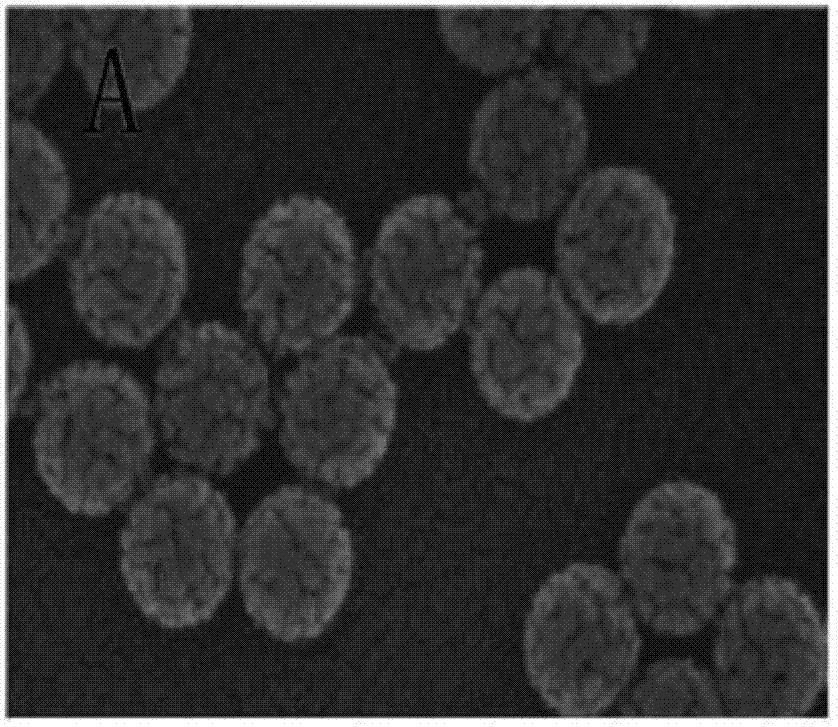

[0048] (1) Preparation of nano-microcapsules of phase change material (A):

[0049] Step 1, according to the mass ratio of phase change material paraffin: the total mass ratio of styrene (ST) and butyl acrylate (BA) is 1:1, the mass ratio of styrene (ST) : the mass of butyl acrylate (BA) The ratio is 10:1, the mass of acrylic acid (AA): the ratio of the total mass of styrene (ST) and butyl acrylate (BA) is 1 / 100, the mass of paraffin: deionized water (H 2 OH) with a mass ratio of 10 / 100;

[0050] Step 2, 0.5% sodium dodecylbenzenesulfonate (SDS) and 1% potassium persulfate (KPS) according to the total mass of styrene (ST) and butyl acrylate (BA) taken in step 1;

[0051] Step 3: Add styrene (ST), butyl acrylate (BA) and acrylic acid (AA) weighed in steps 1 and 2 into deionized water, mix, and stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com