Efficient and energy-saving hollow film glass

A high-efficiency, energy-saving, hollow technology, applied in the direction of parallel glass structures, windows/doors, building components, etc., can solve the problems of increased design and processing costs, increased sealing difficulty, increased building installation costs, etc., to achieve manufacturing process and cost Problem optimization, sealing structure and other problem solving, production cost optimization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

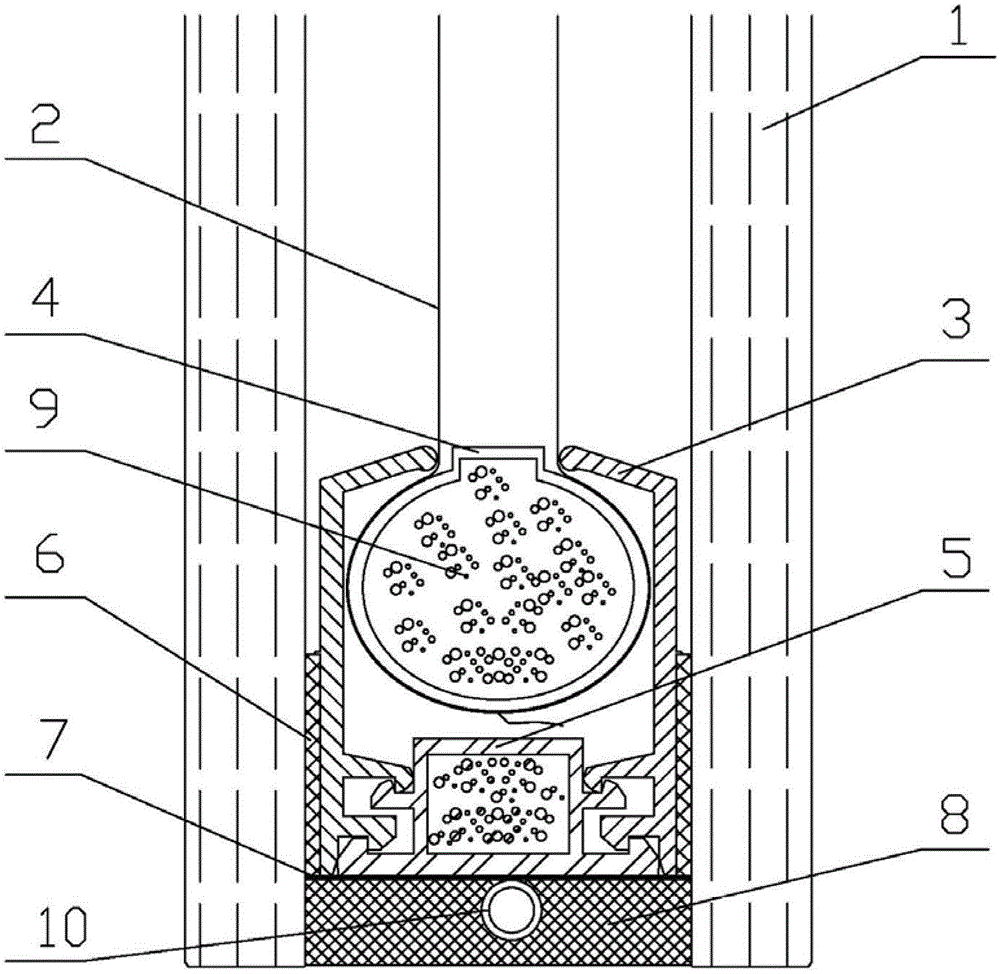

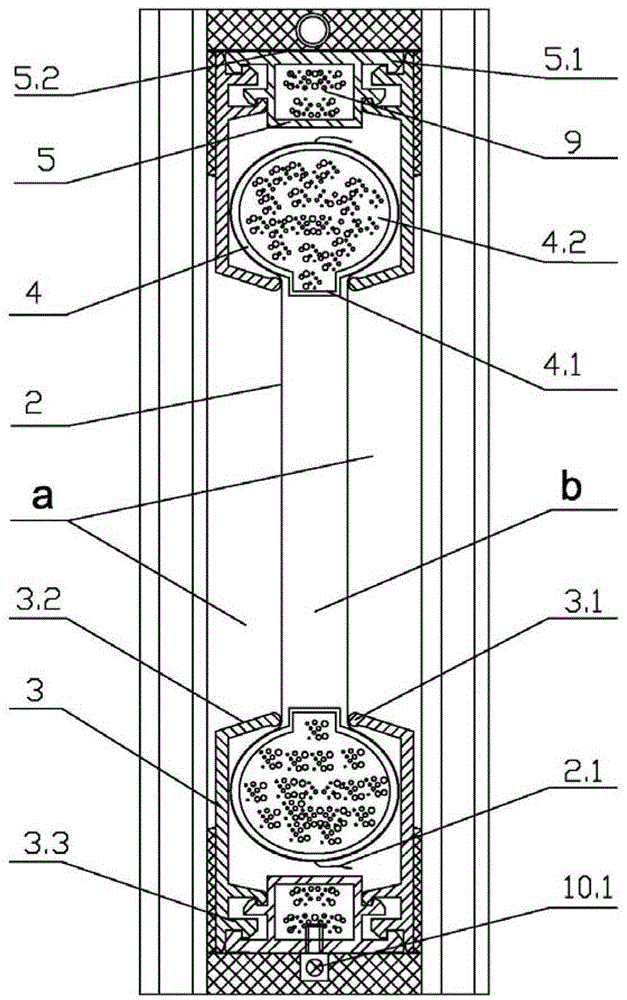

[0029] see Figure 1 to Figure 5 , a kind of high-efficiency energy-saving hollow film layer glass, in the sealed space formed by two pieces of glass 1, a plastic film bag 2 sealed around the edges is built in to form an inner hollow heat insulation layer composed of two pieces of plastic film, and the plastic film bag Two outer hollow insulation layers are formed between 2 and two pieces of glass 1, and the inner hollow insulation layer and the outer hollow insulation layer communicate with the outside world through the breathing valve 10.1 and the breathing tube 10 through the ventilation nozzle 10.2 and according to the ventilation sequence.

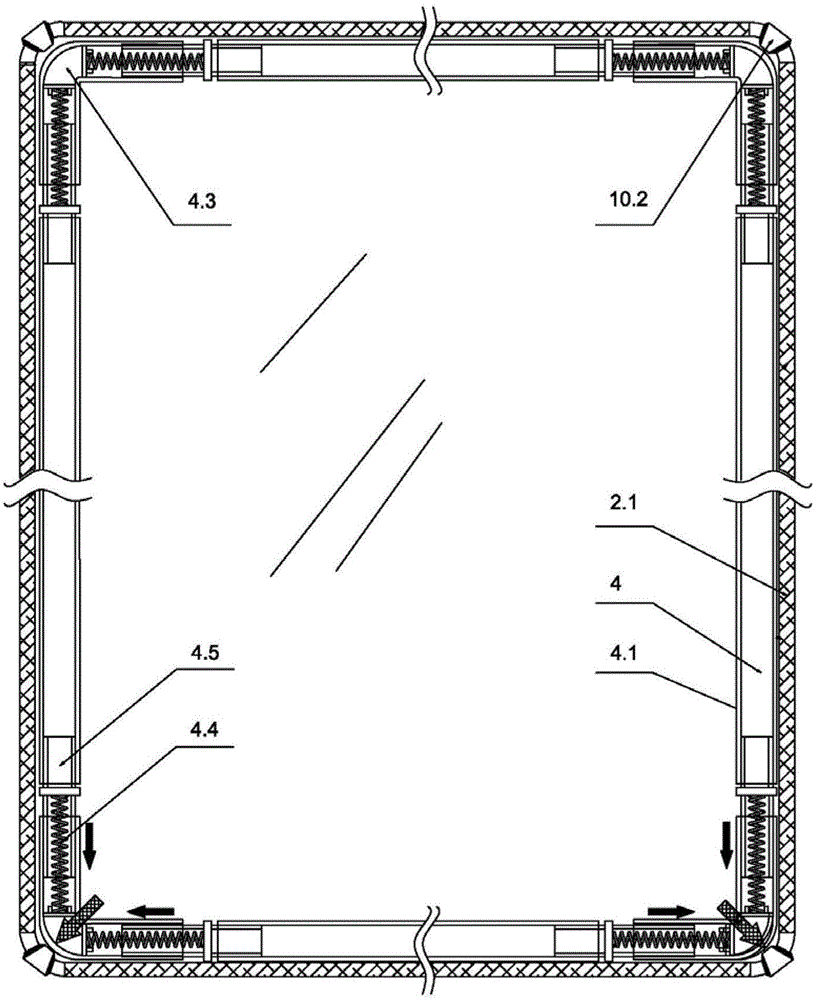

[0030] A tensioning frame 4 is installed inside the plastic film bag 2, and the tensioning frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com