Ecotypic-gypsum-based dry powder coating

A dry powder-based, ecological technology, applied in the field of ecological gypsum-based dry powder coatings, can solve the problems of high packaging and transportation costs, poor durability, and easy cracking, and achieve low manufacturing costs, simple production processes and equipment, and high hiding power. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

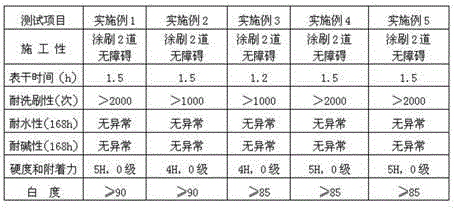

Examples

Embodiment 1

[0025] The distribution ratio of each component in this embodiment: gypsum powder 35kg, superfine slag powder 20kg, white cement 5kg, quicklime 6kg, light calcium carbonate 16.7kg, titanium dioxide 8kg, polyvinyl alcohol micropowder 8kg, bentonite 1kg, sodium hexametaphosphate 0.1 kg, methylcellulose 0.1kg, polysiloxane 0.1kg.

[0026] Put the above-mentioned raw materials into a high-efficiency mixer, stir for 15 minutes, mix thoroughly, and serve. It can be used after adding appropriate amount of water and fully reconciling. The weight ratio of dry powder to water is 1:0.9.

Embodiment 2

[0028] The distribution ratio of each component in this embodiment: gypsum powder 50kg, superfine slag powder 9kg, white cement 5kg, quicklime 2kg, light calcium carbonate 22.6kg, titanium dioxide 4kg, polyvinyl alcohol micropowder 6kg, bentonite 1kg, sodium hexametaphosphate 0.1 kg, ethyl cellulose 0.15kg, polyol beauty defoamer 0.15kg.

[0029] Put the above-mentioned raw materials into a high-efficiency mixer, stir for 15 minutes, mix thoroughly, and serve.

[0030] When using, add appropriate amount of water to fully reconcile, the weight ratio of dry powder to water is 1:0.9.

Embodiment 3

[0032] The distribution ratio of each component in this embodiment: gypsum powder 59kg, slag powder 8kg, white cement 5kg, quicklime 3kg, light calcium carbonate 9.6kg, titanium dioxide 4kg, polyvinyl alcohol micropowder 10kg, bentonite 1kg, sodium hexametaphosphate 0.1kg, Ethyl methylcellulose 0.15kg, polysiloxane 0.15kg.

[0033] Put the above-mentioned raw materials into a high-efficiency mixer, stir for 15 minutes, mix well, and serve.

[0034] When using, add appropriate amount of water to fully reconcile, the weight ratio of dry powder to water is 1:0.9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com