Rapid fixing method of temperature probe

A fixing method and temperature probe technology, applied to thermometers, thermometer parts, measuring devices, etc., can solve the problems of unusable vehicles, temperature probe metal bracket and probe position offset, temperature probe winding, etc., to achieve disassembly and assembly operations Simple and convenient, effective and quick to fix the probe, and the effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

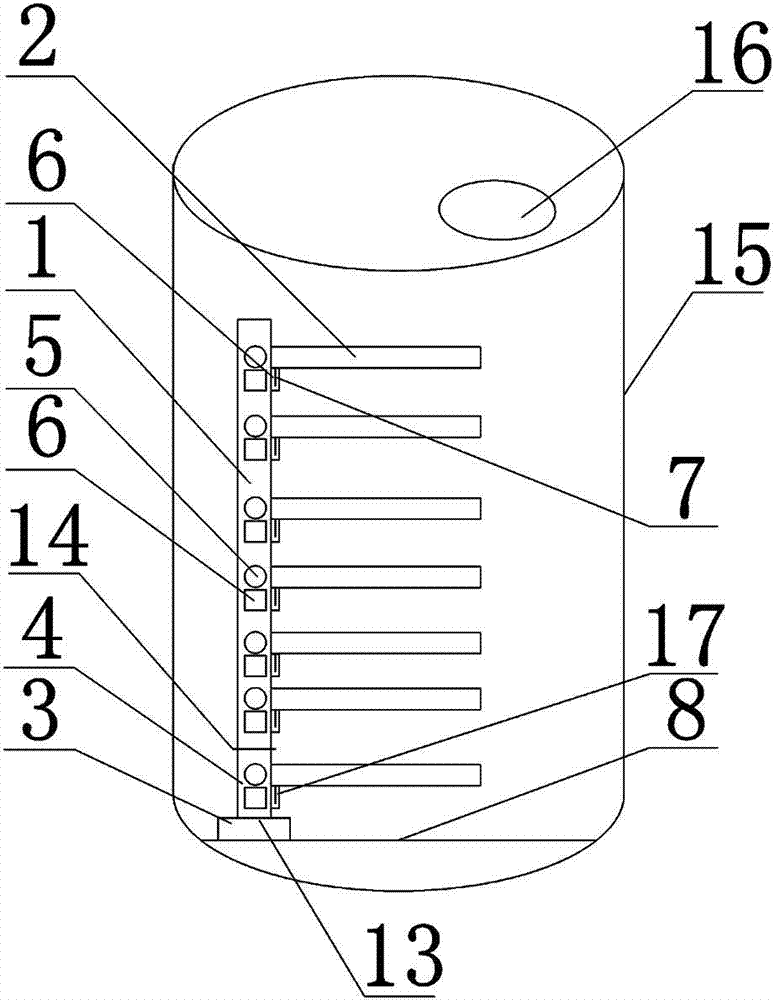

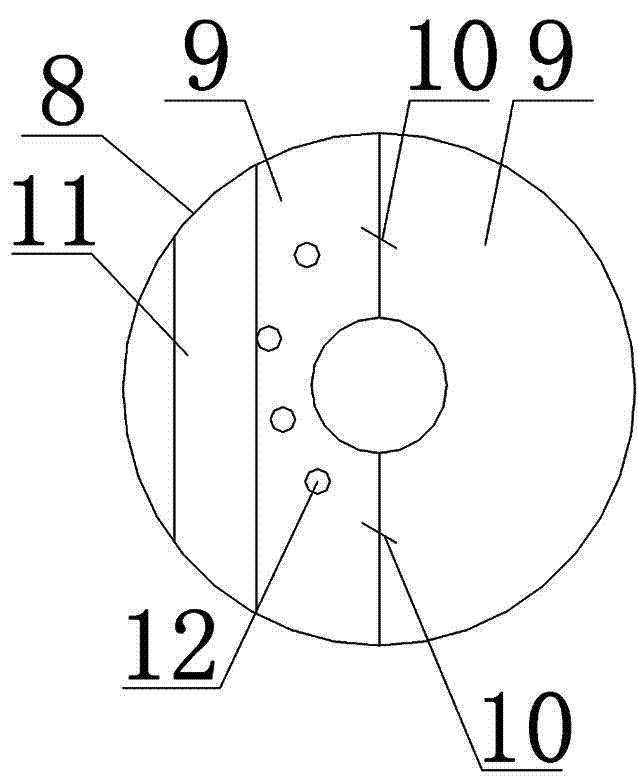

[0027] The present invention will be further described below in conjunction with accompanying drawing:

[0028] Such as figure 1 As shown, the temperature probe fast fixing method includes the following steps:

[0029] A. Positioning, fixing the fixed module in the sterilization container;

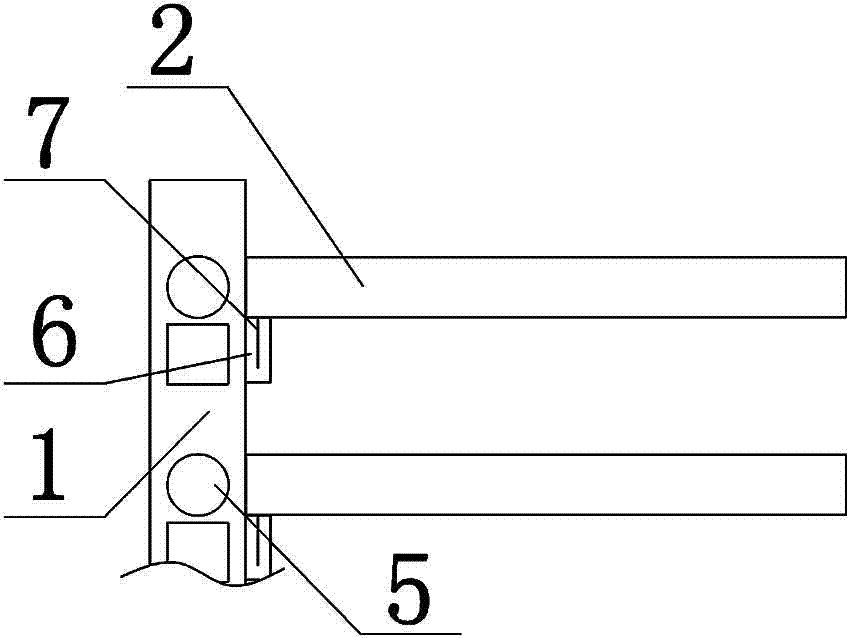

[0030] B. Connection, the mobile bracket 1 is connected with a quick-connect chuck 14, and the mobile bracket 1 at the lowermost end is connected with the fixed bracket 4 of the fixed module with a quick-connect chuck 14; the number of connections of the mobile bracket 1 is determined by the bracket height and The height of the cavity of the bacteria container is determined;

[0031] C. Fix the probe. The probe penetrates through the nozzle of the uppermost mobile bracket 1, and passes through the through hole A5 of the mobile bracket 1. The probe is placed inside the sterilization container, and the mobile sleeve 2 is placed outside the probe. The probe is 1 to 2 cm beyond the moving s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com