Method for measuring pore distribution of porous structure body

A technology of pore distribution and porous structure, applied in suspension and porous material analysis, measurement devices, permeability/surface area analysis, etc., can solve problems such as the inability to meet the pore measurement requirements of lithium-ion battery electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

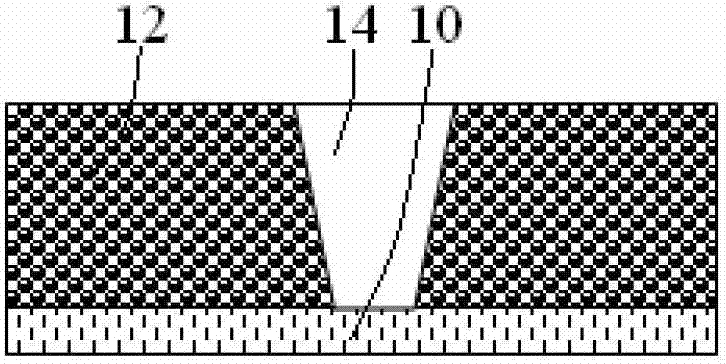

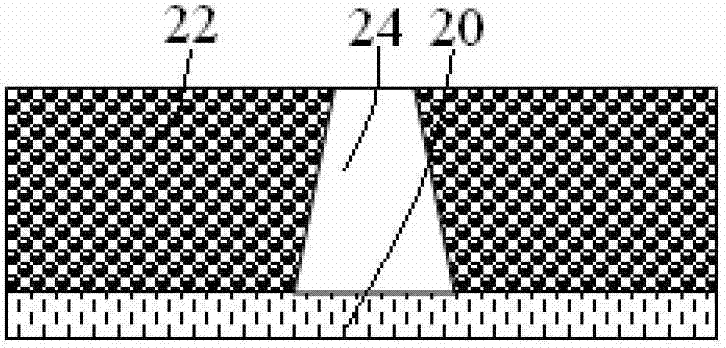

Method used

Image

Examples

Embodiment 1

[0027] Take a 100ml clean beaker and a magnetic stirring bar for use. First configure a dilute nitric acid solution with a concentration of 1M, pipette 12ml of dilute nitric acid solution into a 100ml clean beaker, and add 17 grams of siloxane liquid with a purity of 99.9% to the beaker with a precisely controlled volume pipette gun. The mass ratio of dilute nitric acid to siloxane is 0.7, and the sealed beaker is magnetically stirred at room temperature, and the stirring speed is 1000 rpm. After stirring for 5 minutes, a clear hydrolyzate was obtained.

[0028] Dry the lithium-ion battery cathode sheet to be measured, and use a pipette gun with precise volume control to suck 0.05ml of hydrolyzate and drop it in the middle of the electrode sheet to be tested, and the hydrolyzate will quickly penetrate into the electrode sheet.

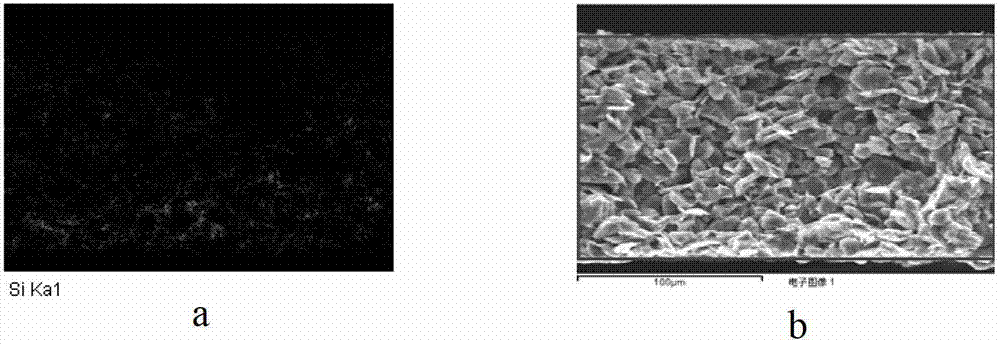

[0029] The above-mentioned cathode sheet was soaked in liquid nitrogen for 10 minutes, and it was brittle after being taken out. Electron scattering...

Embodiment 2

[0031] Take a 100ml clean beaker and a magnetic stirring bar for use. First configure a dilute nitric acid solution with a concentration of 1M, pipette 12ml of dilute nitric acid solution into a 100ml clean beaker, and add 17 grams of siloxane liquid with a purity of 99.9% to the beaker with a precisely controlled volume pipette gun. The sealed beaker is magnetically stirred at room temperature, and the stirring speed is 1000rpm. After stirring for 5 minutes, a clear hydrolyzate was obtained.

[0032] Dry the anode piece of the lithium-ion battery to be measured, use a pipette gun with precise volume control to draw 0.05ml of hydrolyzate and drop it in the middle of the pole piece to be tested, and the hydrolyzate will quickly penetrate into the pole piece.

[0033]The above-mentioned cathode sheet was soaked in liquid nitrogen for 5 minutes, and it was brittle after being taken out. Electron scattering energy spectrometer was used to collect the surface distribution of sili...

Embodiment 3

[0035] Prepare the hydrolyzate of siloxane according to the method in embodiment 1, wherein, dilute nitric acid volume is 20ml, and the siloxane quality that purity is 99.9% is 10 grams, and the mass ratio of dilute nitric acid to siloxane is 2, and uses The same method as in Example 1 was used to calculate the pore size and porosity distribution along the thickness direction of the rolled lithium-ion battery anode sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com