Method for fabricating gradient coil of superconducting magnetic resonance imaging device

A superconducting magnetic resonance and imaging device technology, which is applied in the direction of measuring devices, measuring magnetic variables, instruments, etc., can solve the problem of harsh cooling requirements of gradient coils, achieve accurate winding accuracy, large current-carrying cross-sectional area, and reduce harsh requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below through specific embodiments and schematic diagrams of production methods.

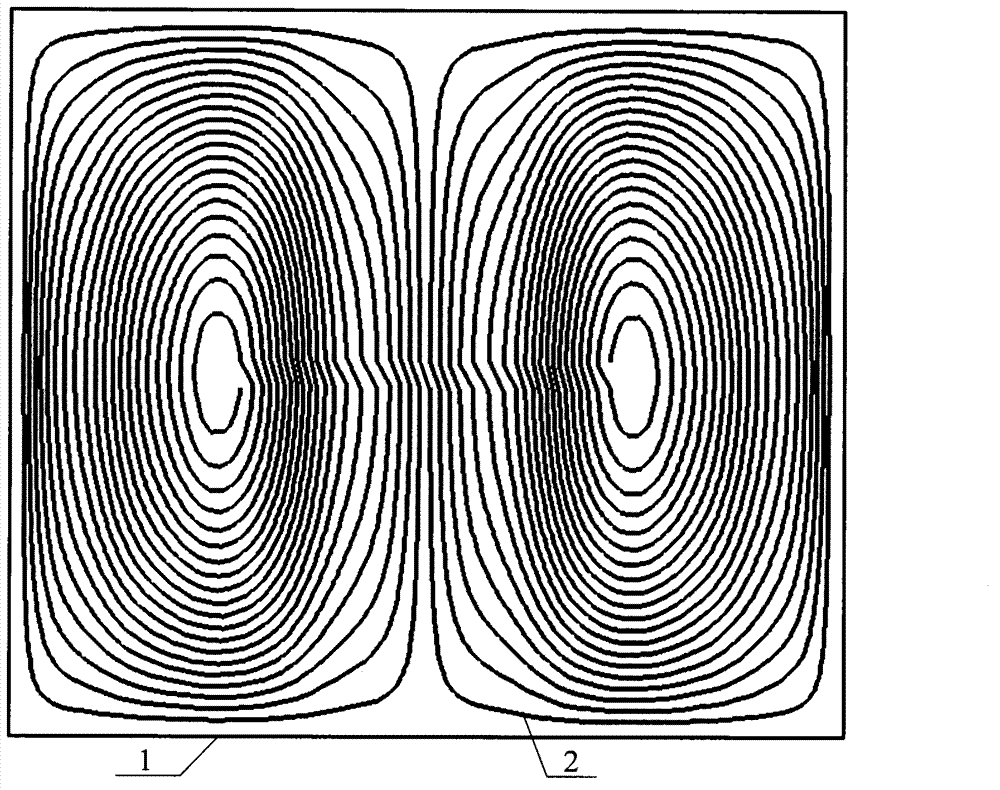

[0019] The structure schematic diagram that the gradient coil that superconducting magnetic resonance imaging device of the present invention is used makes is as figure 1 As shown, its specific production method includes the following steps:

[0020] (1) Use a cutting machine to cut out fingerprint-shaped coils on the copper plate;

[0021] (2) Take off the coil in the red copper plate and clean and air dry;

[0022] (3) Spray thermosetting resin on the surface of the coil, and the thermal conductivity of the resin is greater than 1W / (m K); the use of thermosetting resin can immediately solidify the resin sprayed on the coil, which is convenient for the fixed bonding of the coil and the epoxy board;

[0023] (4) Bond the coil sprayed with resin on the epoxy board and press the epoxy board to fix the coil to it.

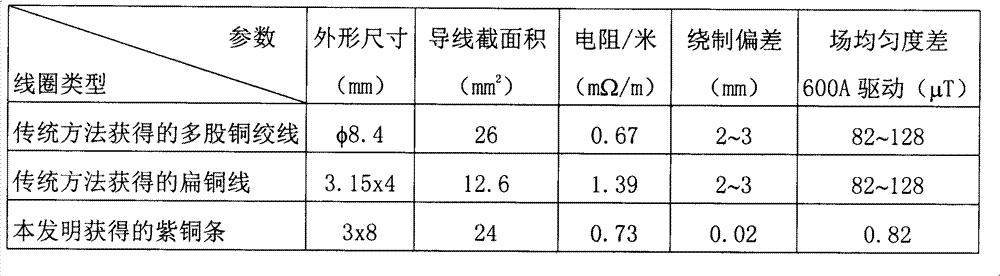

[0024] Use a cutting mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com