Small-volume levocarnitine freeze-dried powder injection and its preparation method and production device

A technology of freeze-dried powder injection and small volume, which is applied in freeze-dried transportation, devices for making medicines into special physical or ingestible forms, powder transportation, etc., which can solve the problems of increased filling volume, reduced output, and low product output. and other issues, to achieve the effect of reducing packaging volume, increasing output, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023]

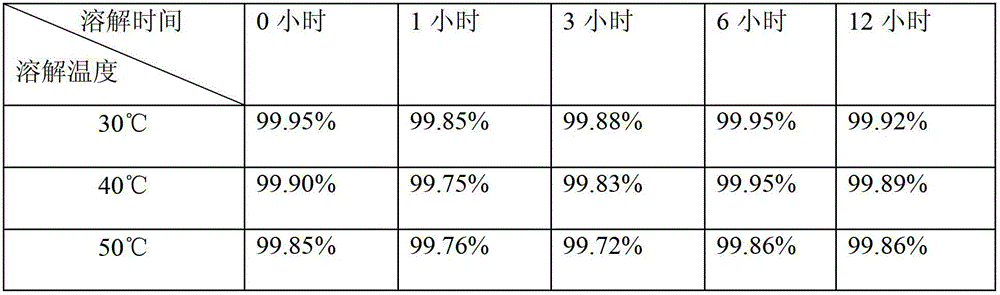

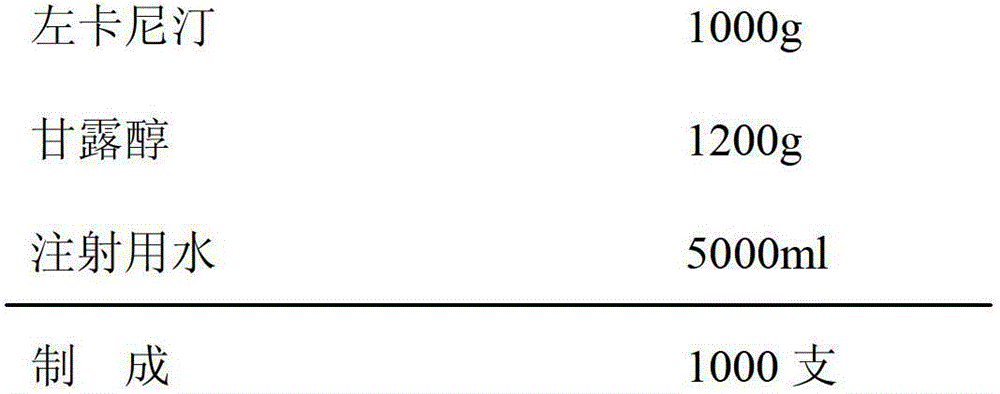

[0024] The preparation method of small-volume levocarnitine freeze-dried powder injection is to lower the temperature below 50°C, add mannitol, stir and dissolve, keep the solution temperature between 30-35°C, then add levocarnitine, and keep the liquid temperature at 30°C ~35°C. After the feed liquid is dissolved, take a sample to test the pH value of the feed liquid, which is required to be controlled between 5.5 and 6.5, and add 0.1% (W / V) activated carbon for decolorization for 30 minutes.

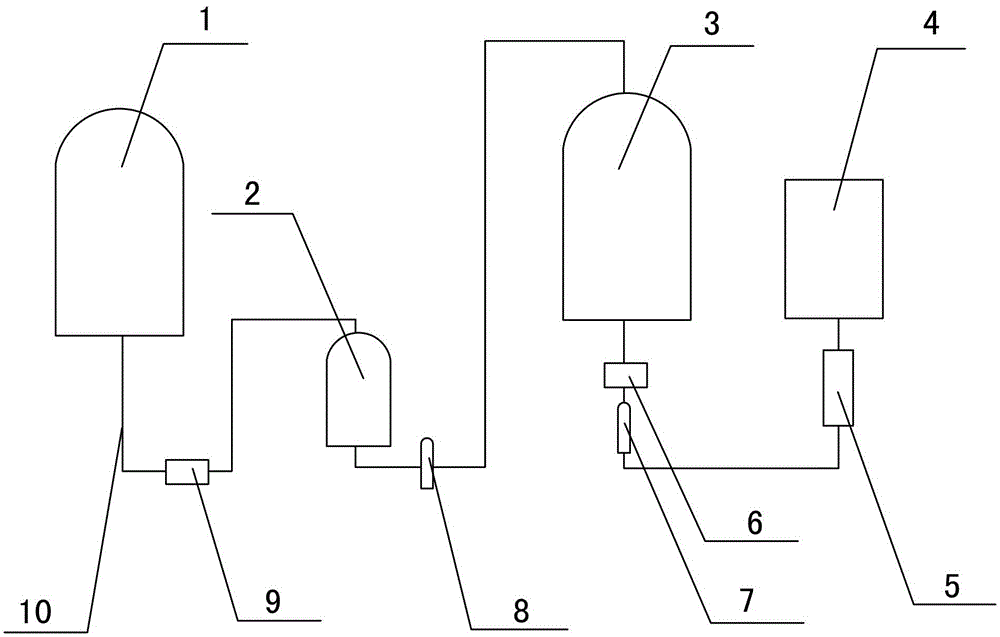

[0025] Turn on the second Grundfos pump 9 and use the titanium rod filter 2 for decarburization and filtration, pass the feed liquid through the second sterilizing filter element 8 to sterilize, and transport it to the aseptic insulation solution storage tank 3 for storage. After sterilizing and filtering, add the remaining amount of water for injection at 30-35°C to the heat-preserving dispensing tank 1, transport it to the titanium rod filter 2 through the heat-insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com