Gear cutting machine, end mill and form milling method

一种切削机床、成形铣削的技术,应用在齿轮切削工具、铣刀、带有齿的元件等方向,能够解决长总加工时间等问题,达到加工时间优化、减少磨损现象的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

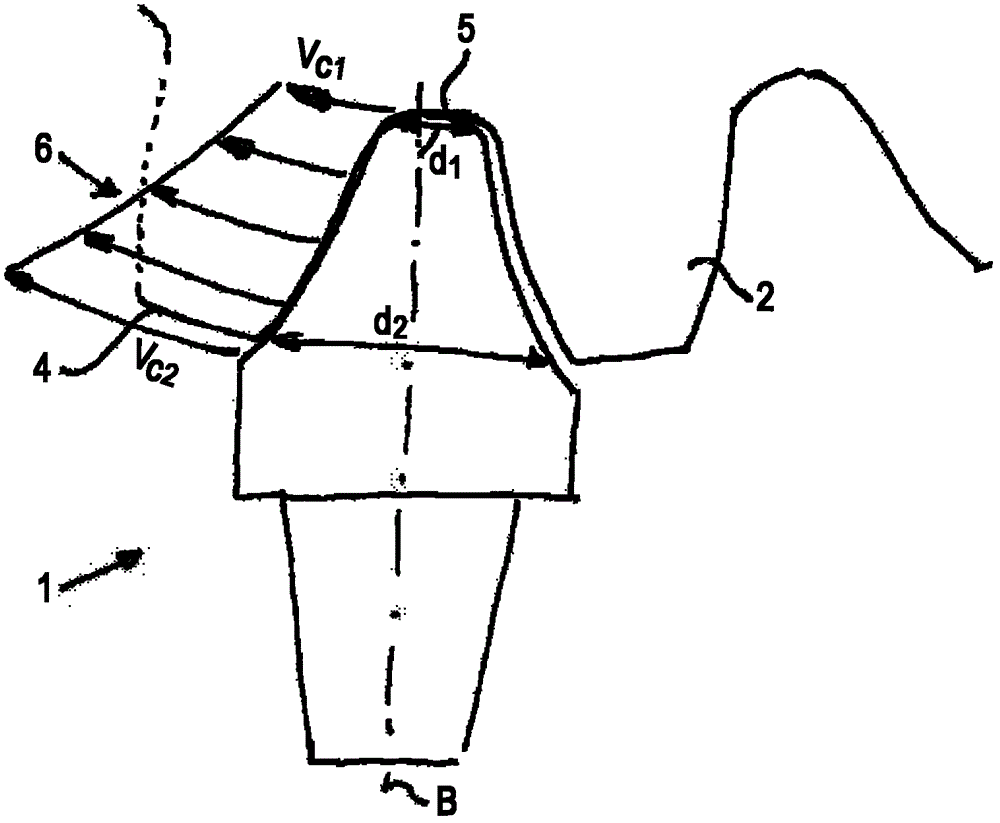

[0027] figure 1 and figure 2 Having already been discussed in the introductory part of the description, details in the views shown will not be discussed again in this part of the description.

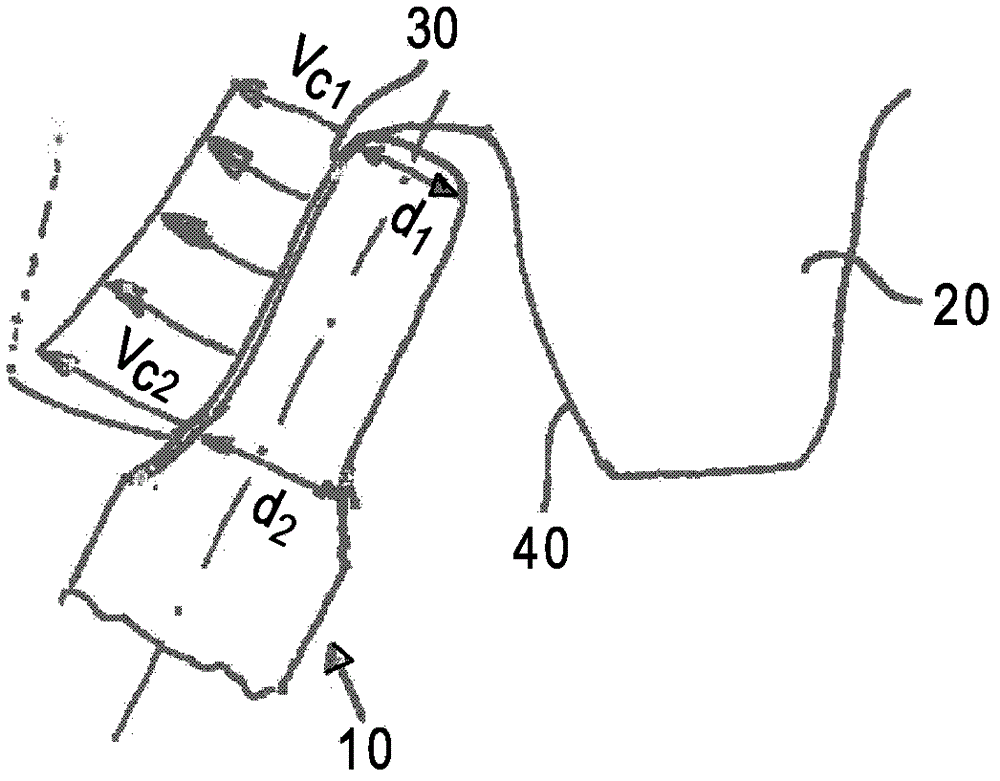

[0028] image 3 A schematic view of an end mill 10 according to the invention is shown, which is cutting a workpiece in the form of a toothed disc 20 with an involute tooth profile. According to the invention, the end mill 10 is mounted on a tool post of a CNC (Computer Numerically Controlled) gear cutting machine and arranged to rotate about a tool axis A. As shown in FIG. The resulting tool speed is designated n and given in revolutions per minute. The machine kinematics aligns the end mill 10 according to the machining of the tooth flanks of the toothed disc 20 . In this respect, either the tool or the tool holder can be moved together with the workpiece or both are combined.

[0029] Figure 4 The machining axis for aligning the end mill 10 is shown. The milling cutter 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com