Harmonic gear grinding device using magnetofluid

A harmonic gear and magnetic fluid technology, applied in the field of gear grinding processing, can solve the problems of inconstant cutting motion speed, inability to discharge, and reduce the strength of the flexible wheel, and achieve the effect of improving grinding efficiency and processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

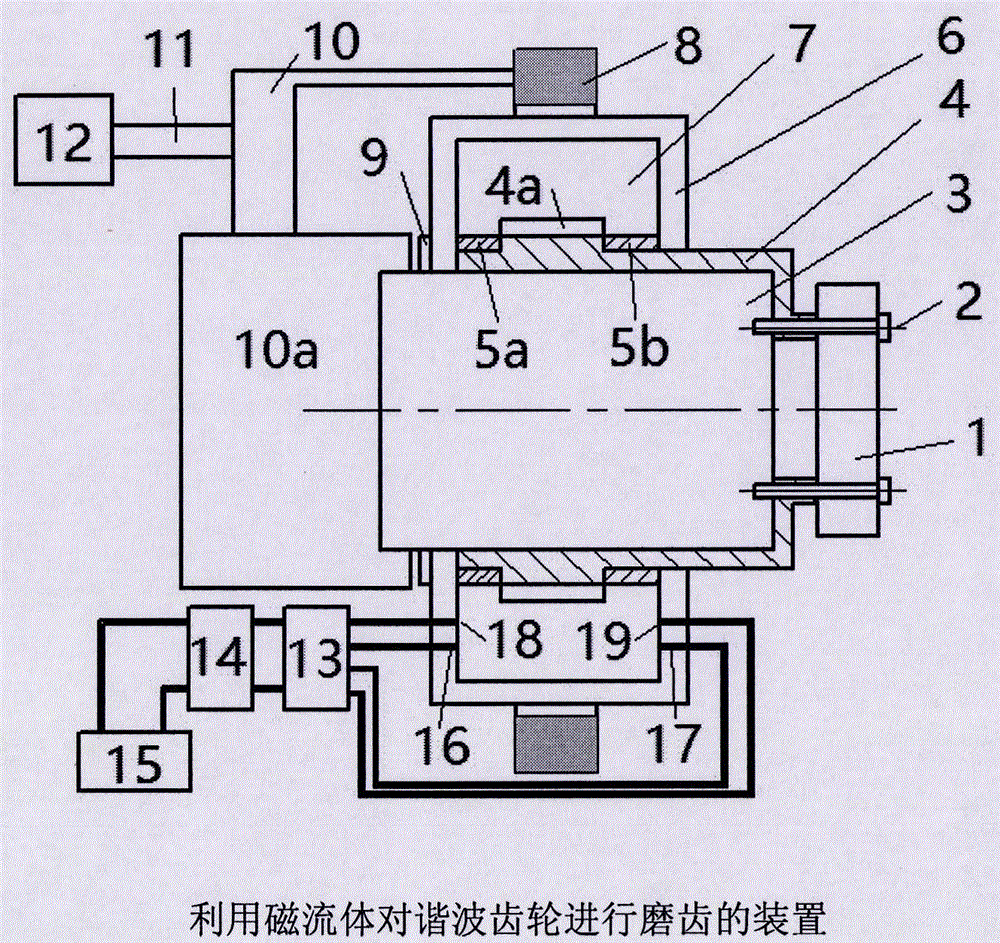

[0015] As shown in the drawings, the flexspline 4 has a ring gear 4a, and a core 3 is installed inside the flexspline 4. The core 3 keeps the inner hole of the flexspline 4 cylindrical, and the flexspline 4 and the core 3 pass through a coupling 2 is fixed on the machine base 1; the left and right sides of the ring gear 4a on the flexspline 4 are respectively equipped with a sealing sleeve 5a and a sealing sleeve 5b, and the sealing shell 6 is connected to the flexspline core 3 through the connection 9 and then connected to the flexspline 4 or The gear ring 4a is positioned and fixed relatively, the sealing sleeve 5a and the sealing sleeve 5b protect the flex spline 4 inside the sealing housing 6 other than the ring gear 4a from grinding; the ring magnet 8 forms a movable connection with the positioning member 10a through the coupling 10 , the coupling 10 and the positioning piece 10a form a moving pair with an axial movement degree of freedom, the positioning piece 10a is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com