Waveguide window manufacturing method

A manufacturing method and technology of waveguide windows, applied in manufacturing tools, metal processing equipment, welding equipment, etc., can solve problems such as incomplete immersion of liquid tin-lead, reduced forming rate of waveguide windows, uneven surface of waveguide windows, etc. Effects of oxidation, improvement of molding rate, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

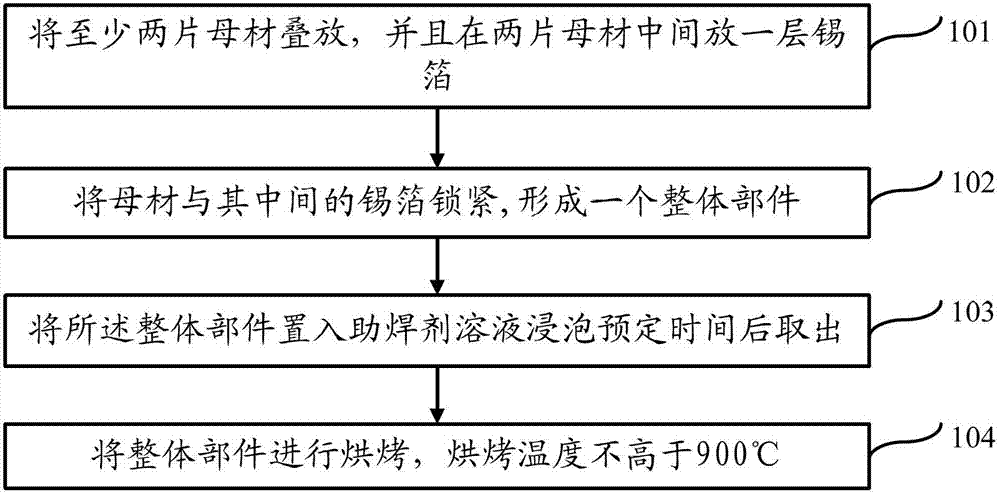

[0044] Such as figure 1 As shown, the manufacturing method of the waveguide window in this embodiment includes the following steps:

[0045] Step 101 is: stack at least two base materials, and place a layer of tin foil in the middle of the base materials.

[0046] Before stacking at least two pieces of base material, it is necessary to press the base material. The pressing process is: place the base material under a specific pressing tool, apply pressure to the specific pressing tool, and press the cross-section of the base material into a specific shape. shape. When the cross-section of the specific pressing tool used is semicircular, the cross-sectional shape of the pressed base material is semicircular, and when the two base materials are stacked, a circular waveguide is formed. When the cross-section of the specific pressing tool used is square, the cross-sectional shape of the pressed base material is square, and when the two base materials are stacked, a square wavegui...

Embodiment 2

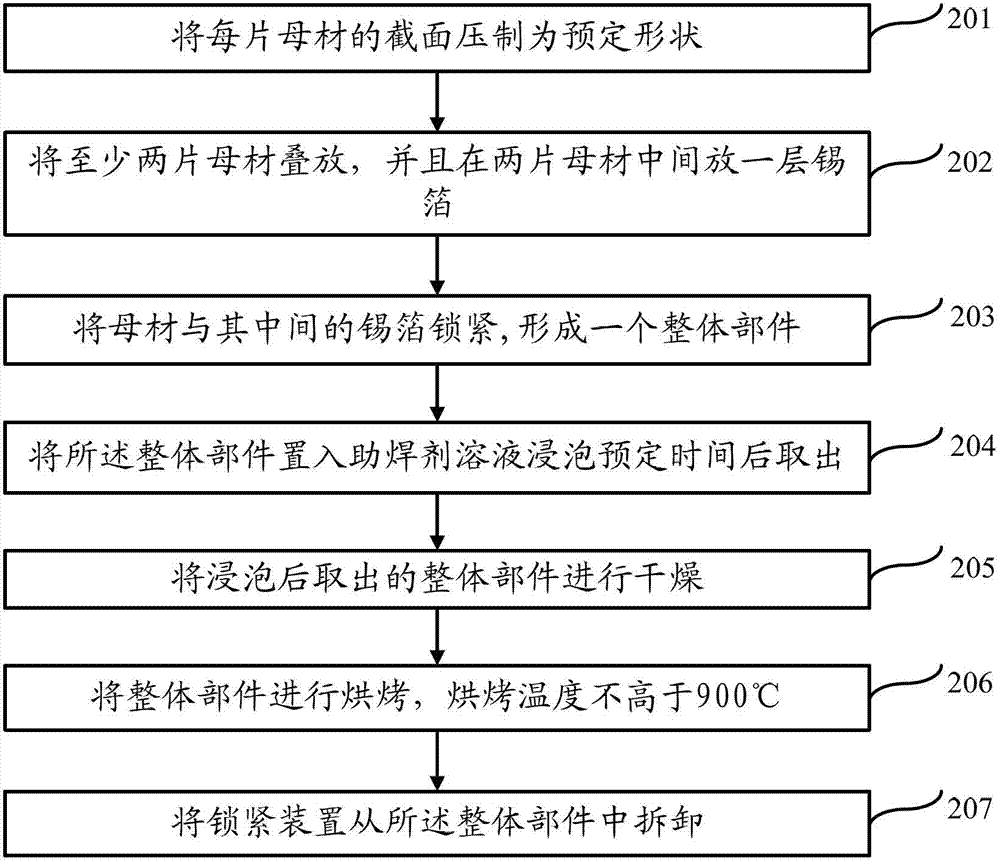

[0057] Such as figure 2 As shown, the manufacturing method of the waveguide window in this embodiment includes the following steps:

[0058] Step 201 is: pressing the cross-section of each base material into a predetermined shape. The base material can be iron base material or copper base material, and the thickness is 0.10-0.20mm. A specific pressing tool can be used in the pressing process; when the cross-section of the specific pressing tool used is semicircular, the cross-sectional shape of the pressed base material is semicircular, and when two pieces of base material are stacked, a circular waveguide is formed. When the cross-section of the specific pressing tool used is square, the cross-sectional shape of the pressed base material is square, and when the two base materials are stacked, a square waveguide is formed. When the cross-section of the specific pressing tool used is tooth-shaped, the cross-sectional shape of the pressed base material is tooth-shaped, and wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com