Digitalized assembly system for bodies of large planes

An assembly system and fuselage technology, applied in aircraft assembly, aircraft parts, ground installations, etc., can solve the problems of low assembly quality and efficiency, failure to meet the long life and high reliability requirements of civil aircraft, and achieve improved connection quality and Efficiency, improving assembly efficiency and quality, and reducing tooling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

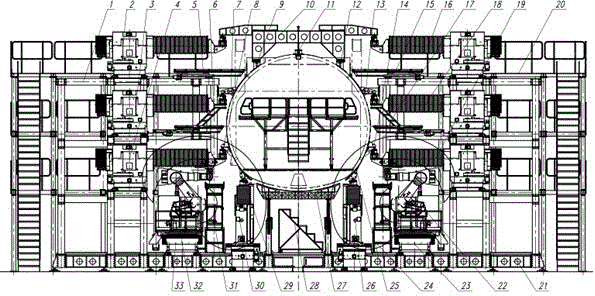

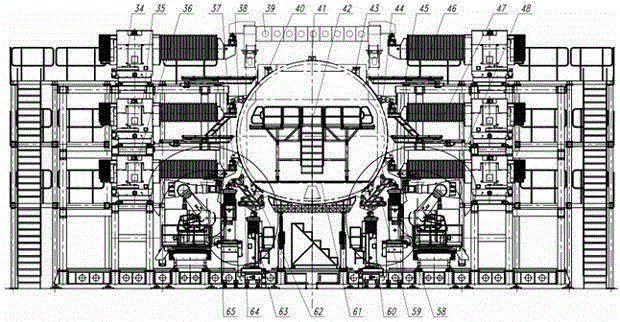

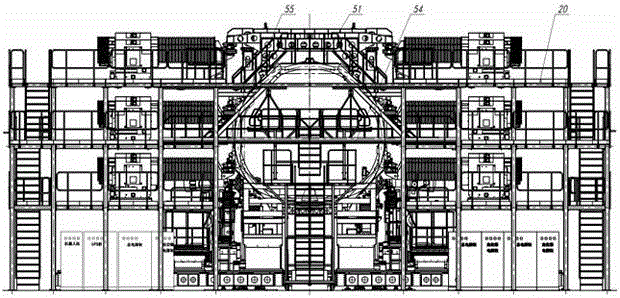

[0034] as attached figure 1 , 2 , 3, 4, 5, and 6, the fuselage digital assembly system used in large aircraft includes the basic platform 21 of the attitude adjustment and positioning system, the attitude adjustment locator unit, the conformal frame, the process joint, the end face conformal frame positioner, Craft floor 61, modular exterior operator station and robotic processing equipment.

[0035] The basic platform 21 of the attitude adjustment and positioning system is fixed on the workshop floor, the attitude adjustment locator unit, the end face conformal frame locator and the robot processing equipment are installed on the attitude adjustment and positioning system basic platform 21, the conformal frame is provided with process joints, and Connected with the attitude adjustment locator unit, the end face shape retaining frame locator includes a front end face shape retaining frame locator 50 and a rear end face shape retaining frame locator 51, and a The process floo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com