Purification method for high-purity organic solvent n-butyl alcohol

A technology of organic solvent and purification method, which is applied in the field of purification of high-purity organic solvent n-butanol, can solve the problems of undiscovered patent documents, etc., and achieve the effects of saving manpower, significant economic benefits, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A purification method of high-purity organic solvent n-butanol, the steps are as follows:

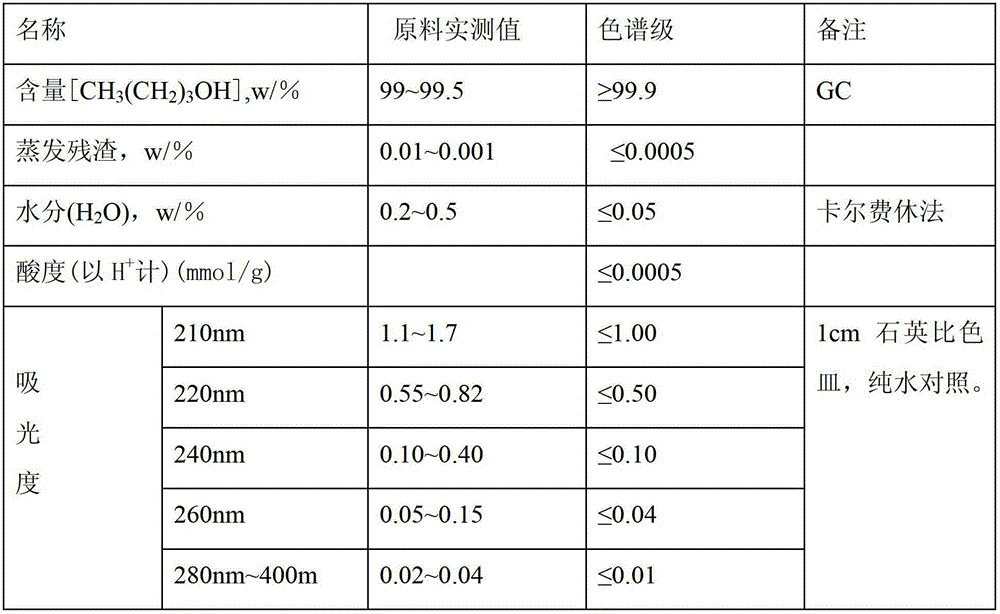

[0021] ⑴ The raw material n-butanol (content is about 99.5%) is lifted to the top of the adsorption column, and the n-butanol raw material is adsorbed at a speed of 60mL / min; the adsorption column is 1.2M high and 3.8cm in diameter. The two columns are respectively equipped with silica gel, Diatomaceous earth, the particle size is 0.5~1.0mm and 0.3mm~0.8mm, two columns are connected in series, the amount of adsorbent is 4 / 5 of the column height. In the column, n-butanol is in full contact with silica gel and diatomaceous earth adsorbent to adsorb and remove most of the organic impurities such as aldehydes, ketones and esters. After the adsorbed liquid is nearly qualified (see Table 1 for specific technical indicators), Go to the next step and remove the pre-adsorption fraction.

[0022] ⑵Put the n-butanol flowing out of the adsorption column into the drying column, the column height ...

Embodiment 2

[0026] A purification method of high-purity organic solvent n-butanol, the steps are as follows:

[0027] ⑴ The raw material n-butanol (content is about 99.5%) is lifted to the top of the adsorption column, and the n-butanol raw material is adsorbed at a speed of 120mL / min; the adsorption column is 1.2M high and 3.8cm in diameter. The two columns are equipped with silica gel, Diatomite, the particle size of which is 0.5~1.0mm and 0.3mm~0.8mm, two columns are connected in series, the amount of adsorbent is 4 / 5 of the column height. In the column, n-butanol is in full contact with silica gel and diatomaceous earth adsorbent to adsorb and remove most of the organic impurities such as aldehydes, ketones and esters. After the adsorbed liquid is nearly qualified (see Table 1 for specific technical indicators), Go to the next step and remove the pre-adsorption fraction.

[0028] ⑵Put the n-butanol flowing out of the adsorption column into the drying column, the column height is 1.2M, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com