Carbon roasting smoke calcium hydroxide desulfurization and defluorination purification method and device

A calcium hydroxide and purification device technology, applied in chemical instruments and methods, combined devices, separation methods, etc., can solve the problems of flue gas not meeting emission standards, secondary pollution, unstable equipment operation, etc., and achieve a reasonable purification method. Simple, small equipment footprint, and reasonable device design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

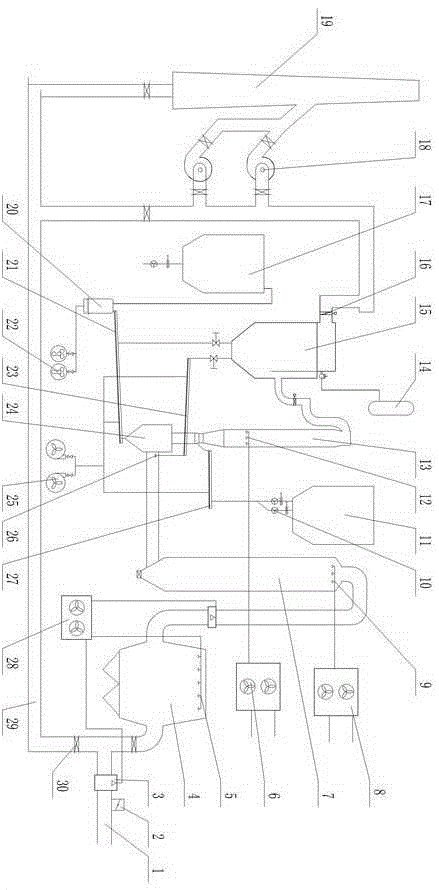

[0024] Depend on figure 1 As shown, the flue gas produced by the carbon roasting furnace passes through the flue 1, there is a cold air valve 2 at the entrance of the flue 1, the pipeline flood fire extinguishing group 3, and enters the pre-dust collector 4, and part of the dust and tar are removed in the pre-dust collector 4 , the flue gas enters the full evaporative dry bottom cooling tower 7 for spraying and cooling. On the upper part of the full evaporative dry bottom cooling tower 7, there is a spray water two-fluid atomization spray gun 9, which is connected with the full atomization pump station 8 to ensure The outlet temperature of the total evaporative dry bottom cooling tower 7 is controlled at 80±5°C. This temperature can be adjusted. The flue gas after cooling enters the adsorption reaction separator 24, and there is a dispersion distributor 26 at the entrance of the adsorption reaction separator 24 to circulate Calcium hydroxide is sprayed in, and the circulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com