Purification method for silver nanowire

A technology of silver nanowires and purification method, applied in nanotechnology and other directions, can solve problems such as time-consuming, and achieve the effects of easy availability of raw materials, simple operation process and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

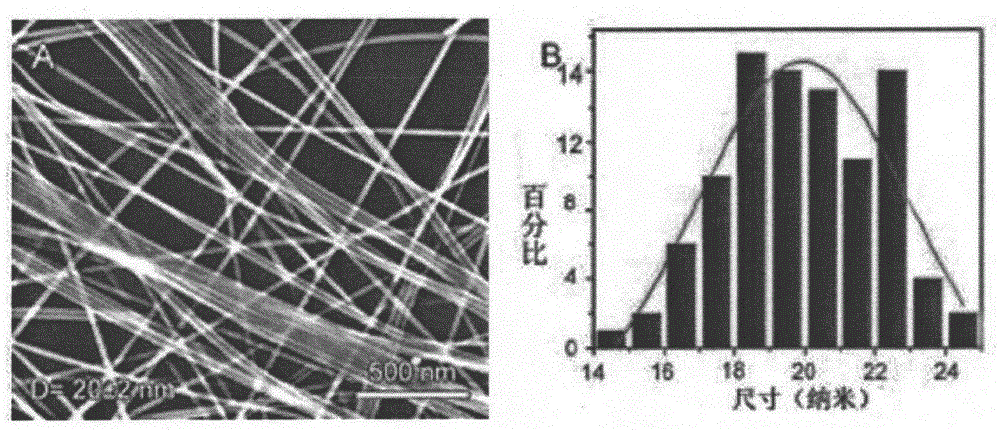

[0023] Silver nanowires were prepared by traditional polyol method (Sun, Y.G.; Xia, Y.N. Adv. Mater. 2002, 14, 833-837; Bergin, S.M.; Chen, Y.H.; Rathmell, A.R.; Charbonneau, P.; Li, Z.Y. ; Wiley, B.J. Nanoscale 2012, 4, 1996-2004.). figure 1 For the information of the prepared silver nanowires, it can be seen from the figure that the diameter of the prepared nanowires is about 20nm, and the diameter distribution is uniform.

Embodiment 2

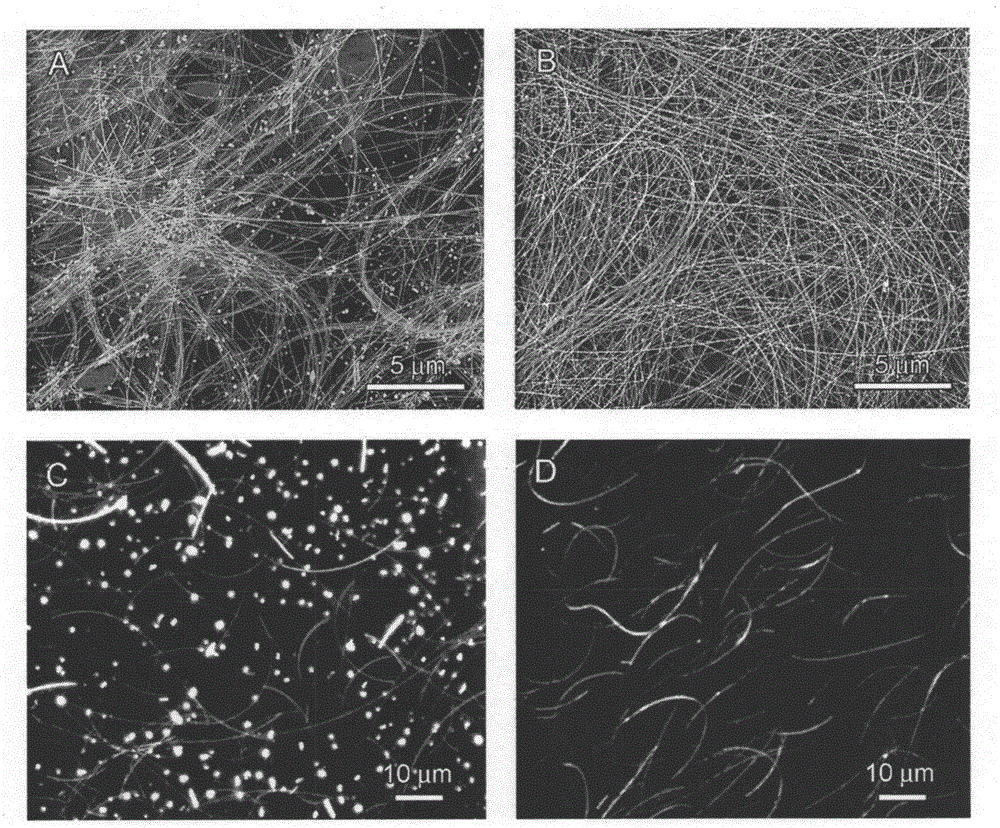

[0025] A kind of purification method of silver nanowire, concrete steps are: the average diameter that will be synthesized by polyol method is 20 nanometers, the silver nanowire 0.02g that average length is 60 microns is dispersed in 10mL mass fraction and is 0.5% polyvinylpyrrolidone ( PVP) aqueous solution to obtain the silver nanowire dispersion, add acetone, its volume is 4 times of the silver nanowire dispersion, so that the silver nanowires are reunited, let stand for 10min, and remove the upper liquid. Repeat the above steps 3 times to obtain the purified silver nanowires. figure 2 This is the comparison chart after four times of purification, it can be seen that the purity of the nanowires has been significantly improved.

Embodiment 3

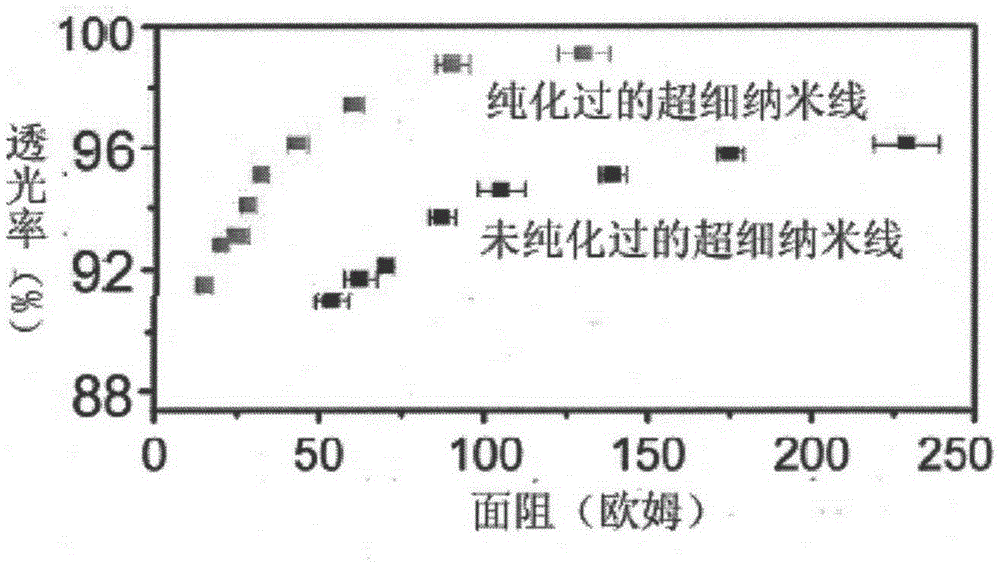

[0027] The nanowires were made into a uniform film on a glass substrate by the Meyerrod method, and its light transmittance and area resistance were tested. image 3 It shows that the purified nanowires show more excellent performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com