Material with characteristics of fire retardation, thermal insulation and wave absorption, and preparation method thereof

A wave-absorbing material and wave-absorbing agent technology, applied in light weight, can solve the problems of complex material preparation process, high material quality, short life, etc., and achieve good flame retardant and heat insulation performance, high wave absorption strength, and small area density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

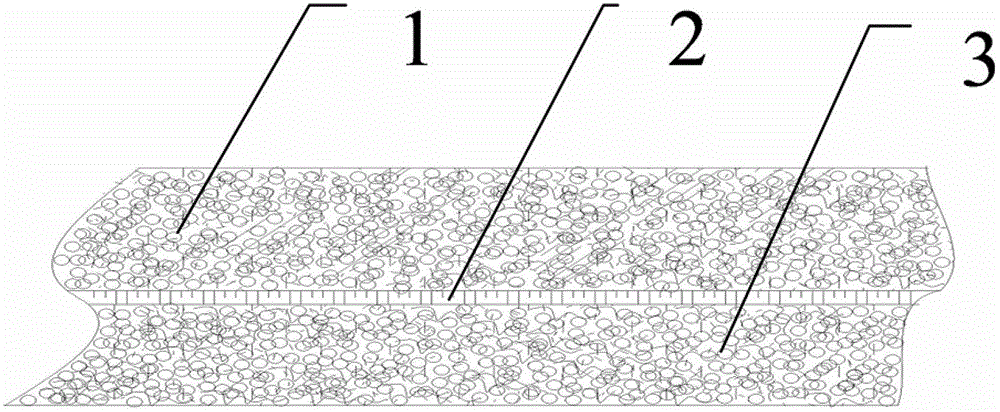

[0079] Add a wave absorbing agent to the PVC binder, the ratio of wave absorbing agent to binder is 12:13, the wave absorbing agent includes nickel-plated hollow glass microspheres, and nickel-plated carbon fiber and polycrystalline iron fiber are also added , the mass ratio of the three components is 3:1:8.

[0080] The mesh is polyester fiber mesh with a thickness of 100 microns. The polyvinyl chloride binder is compounded from polyvinyl chloride, a plasticizer and an antioxidant in a ratio of 100:50:2, which is a weight ratio. Nickel-plated hollow glass microspheres and nickel-plated carbon fibers are obtained by palladium activation and electroless plating.

[0081] The preparation method of flame retardant heat insulation and wave absorbing material is as follows:

[0082] Step 1: Prepare the absorber:

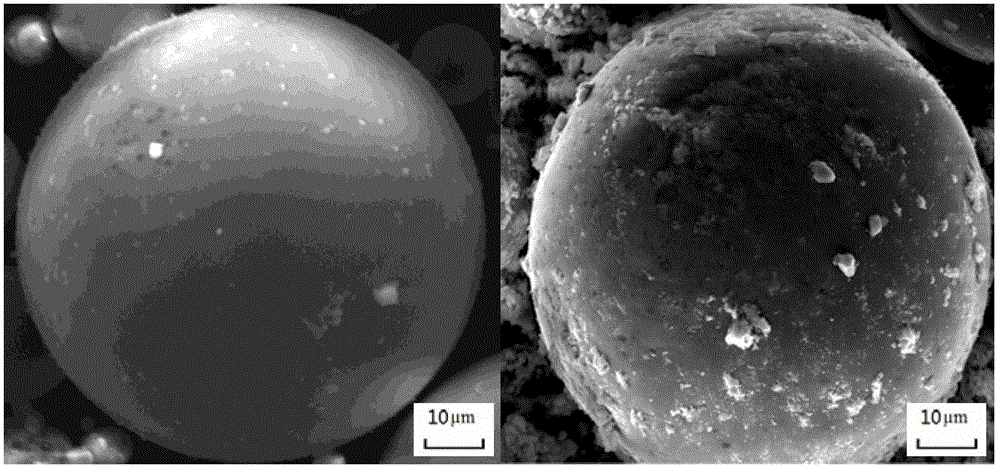

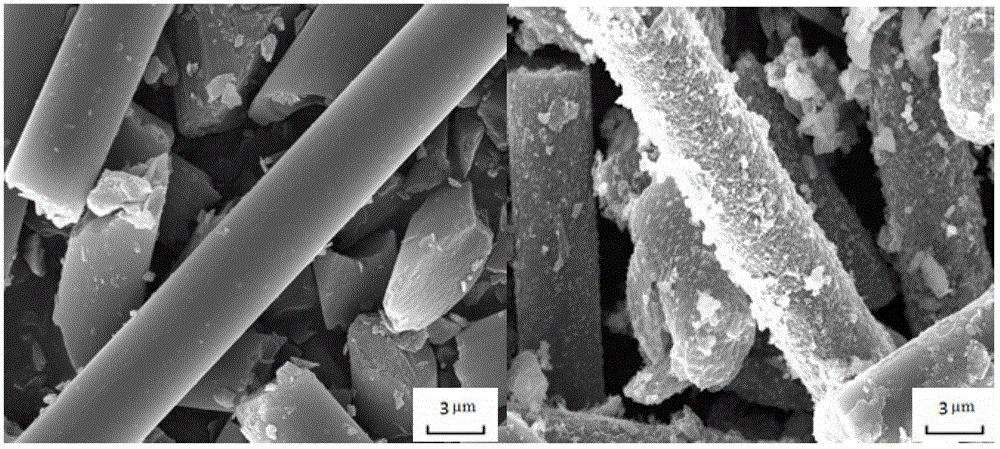

[0083] (1) The specific palladium activation and electroless plating methods of hollow glass microspheres are:

[0084] First, pretreatment of hollow glass microspher...

Embodiment 2

Embodiment 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com