Coke oven machine side dust collection device with ground dust collection station

A technology of dust removal device and ground, applied in coke oven, furnace prevention/removal of scale, petroleum industry, etc., can solve the problem of increasing water supply and drainage and its control process, vehicle-mounted dust removal system cannot play the role of machine-side dust collection, equipment cost and The problem of high operating costs has achieved significant economic benefits, novel structure, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

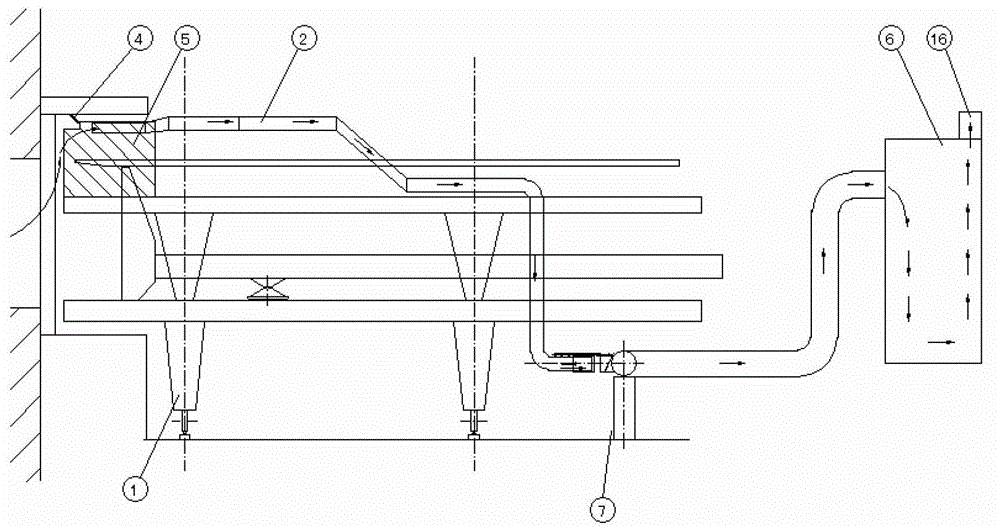

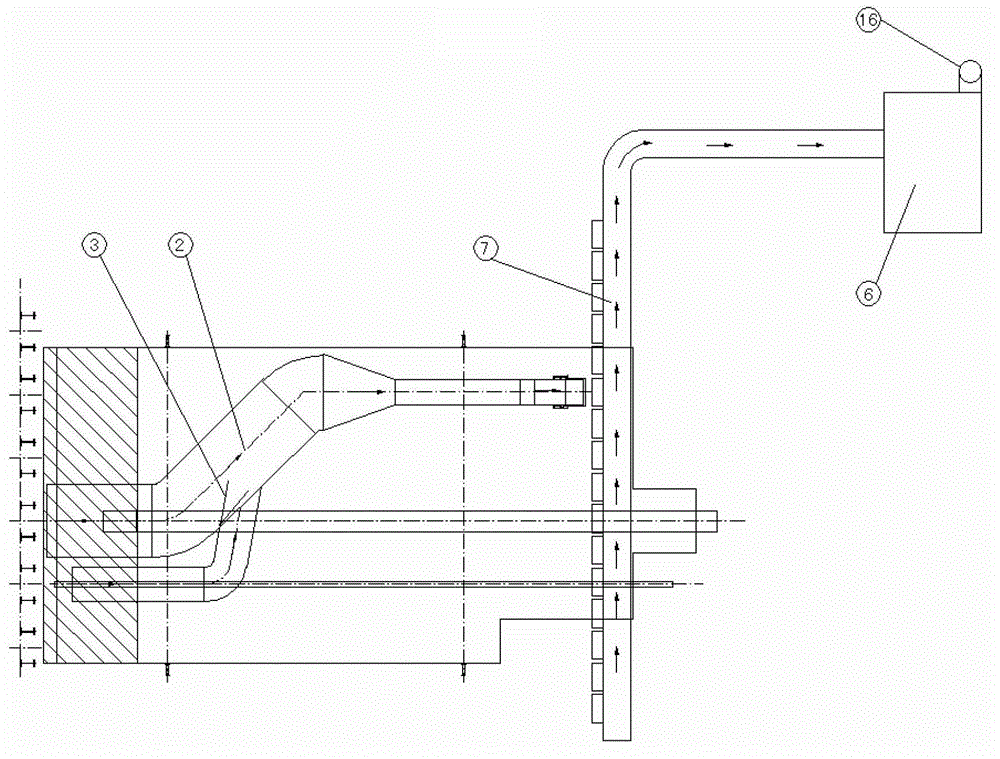

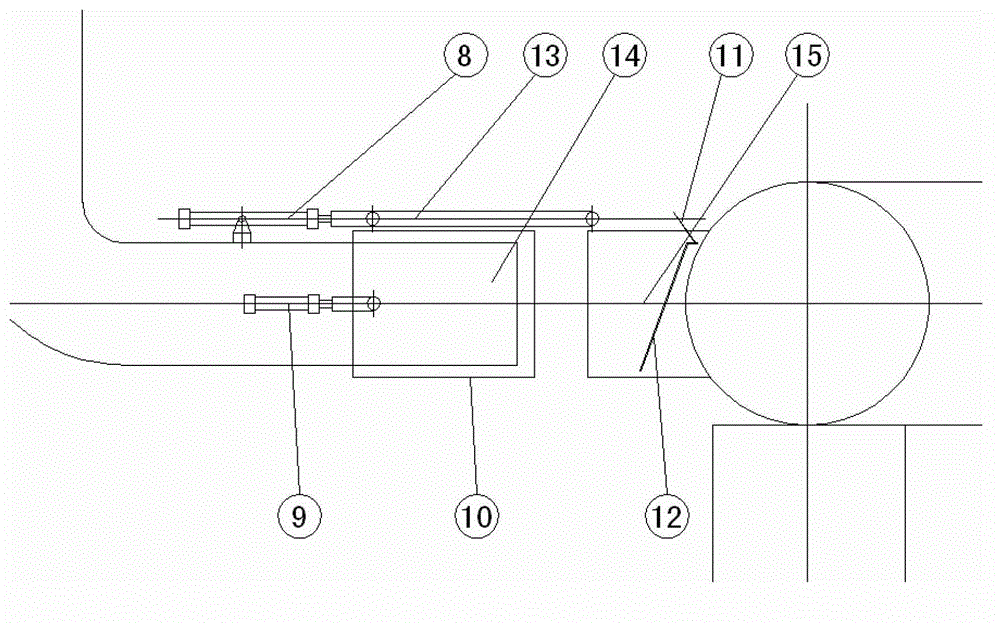

[0028] The specific embodiment of the present invention is shown in accompanying drawing, it is characterized in that comprising on-board pipeline 2, regulating valve plate 3, furnace mouth movable baffle plate 4, furnace mouth fume cover 5, ground pipeline 7 and dust collector 6; Furnace mouth smoke cover 5 Installed at the position where the coke pusher 1 is connected to the furnace mouth; the furnace mouth movable baffle plate 4 is installed at the front end of the furnace mouth hood 5; the on-machine pipeline 2 is equipped with a regulating valve plate 3; the on-machine pipeline 2 is installed on the coke pusher 1 One end is mounted on the rear part of the furnace mouth movable baffle 4 on the furnace mouth hood 5, and the other end is freely docked with one end of the ground pipe 7 through a docking valve 14; the other end of the ground pipe 7 is connected with the dust collector 6; A chimney 16 is installed on the dust collector 6 .

[0029] Fire mouth movable baffle pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com