Manufacture method for PU embossed color-changing decoration leather

A manufacturing method and technology of decorative leather, applied in lamination devices, chemical instruments and methods, lamination, etc., can solve the problems of long pressure change time, poor surface flatness, high pressure change temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

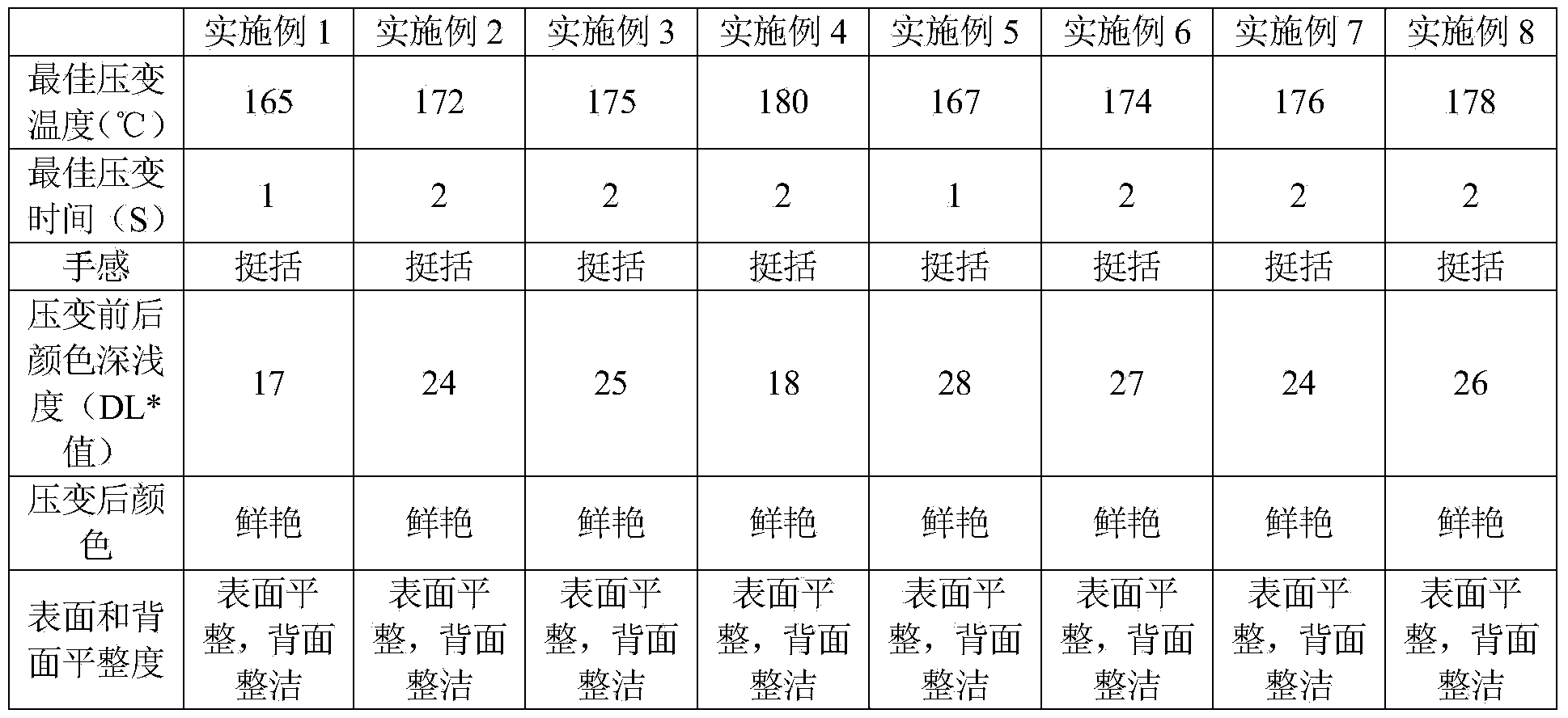

Examples

Embodiment 1

[0040] (a) Prepare spunlace non-woven fabric (thickness is 0.4mm, density is 80g / m) 2 , the fiber is viscose fiber), unwinding and ironing;

[0041] (b) Scraping pressure-changeable polyurethane working paste, the formula ratio of the working paste is calculated as:

[0042] High modulus resin (HX-7240HV): 20 parts,

[0043] Low modulus resin (HX-7087): 80 parts,

[0044] Solvent (DMF): 100 parts,

[0045] Filler (FD600 / 30): 15 parts,

[0046] Organic Color Paste (BLPW-100): 2 parts,

[0047] Organic Color Paste (BLPW-200): 2 parts,

[0048] Organic Color Paste (BLPW-556): 2 parts,

[0049] Micropore Conditioner (OT-70): 1 part,

[0050] Defoamer (SHY-7725): 0.2 parts,

[0051] Leveling agent (JFR-930): 0.3 part;

[0052] The viscosity of the working pulp is 2500cps / 30℃, and the coating weight is 1.5kg / m; the time for the non-woven fabric to enter the coagulation bath after scraping the working pulp is 20s;

[0053] (c) coagulation and water washing, the mass fractio...

Embodiment 2

[0056] (a) Prepare spunlace non-woven fabric (thickness is 0.4mm, density is 65g / m) 2 , the fiber is viscose polyester fiber), unwinding and ironing;

[0057] (b) Scraping pressure-changeable polyurethane working paste, the formula ratio of the working paste is calculated as:

[0058] High modulus resin (HX-7185): 25 parts,

[0059] Low modulus resin (HX-7055): 75 parts,

[0060] Solvent (DMF): 110 parts,

[0061] Filler (ZCD-HAO-001): 20 parts,

[0062] Organic Color Paste (BLPW-100): 1 part,

[0063] Organic color paste (BLPW-300): 1 part;

[0064] Organic Color Paste (BLPW-556): 1 part,

[0065] Micropore Regulator (S-11): 2 parts,

[0066] Defoamer (DX-25): 0.1 part,

[0067] Leveling agent (DX-ACR): 0.1 part;

[0068] The viscosity of the working pulp is 4000cps / 30℃, and the coating weight is 1kg / m; the time for the non-woven fabric to enter the coagulation bath after scraping the working pulp is 45s;

[0069] (c) coagulation and water washing, the mass fraction...

Embodiment 3

[0072] (a) Prepare spunlace non-woven fabric (thickness is 0.4mm, density is 80g / m) 2 , the fiber is viscose fiber), unwinding and ironing;

[0073] (b) Scraping pressure-changeable polyurethane working paste, the formula ratio of the working paste is calculated as:

[0074] High modulus resin (HX-7300): 30 parts,

[0075] Low modulus resin (HX-7121): 70 parts,

[0076] Solvent (DMF): 90 parts,

[0077] Filler (DL-522): 15 parts,

[0078] Organic Color Paste (BLPW-200): 3 parts,

[0079] Organic Color Paste (BLPW-300): 3 parts,

[0080] Organic Color Paste (BLPW-556): 3 parts,

[0081] Micropore Conditioner (OT-70): 1 part,

[0082] Micropore Regulator (SD-80): 2 parts,

[0083] Defoamer (DX-25): 0.4 parts,

[0084] Leveling agent (DX-ACR): 0.7 parts;

[0085] The viscosity of the working pulp is 3800cps / 30℃, and the coating weight is 2kg / m; the time for the non-woven fabric to enter the coagulation bath after scraping the working pulp is 43s;

[0086] (c) coagulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com