Method for determining content of monomer aromatic hydrocarbons in gasoline through gas chromatography

A technology of aromatics content and gas chromatography, which is applied in the field of determination of aromatics content in gasoline by gas chromatography, can solve the problems of difficult establishment and large dead volume of valve switching system, and achieves easy establishment and operation, good repeatability and accurate quantitative results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

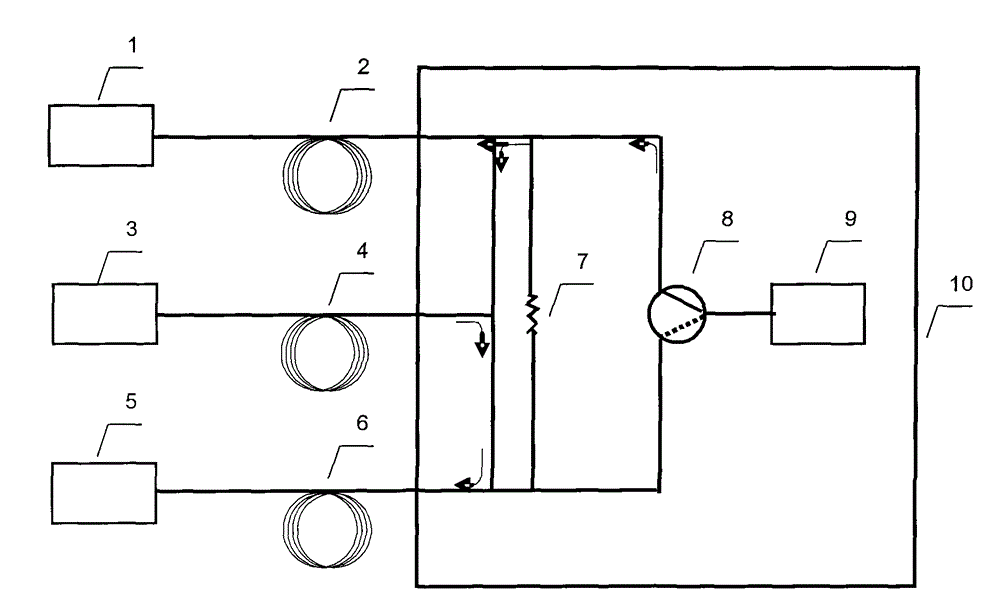

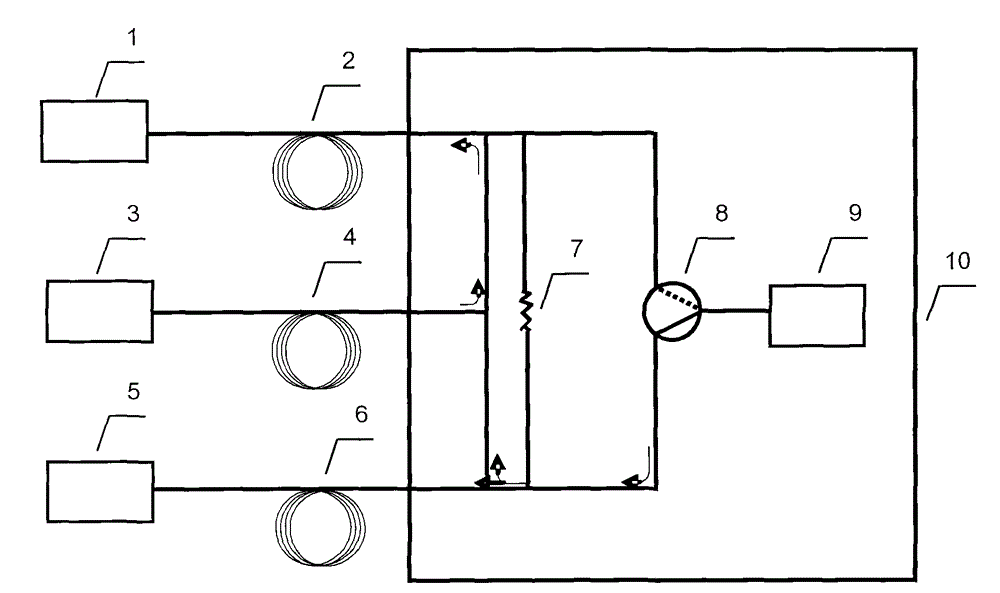

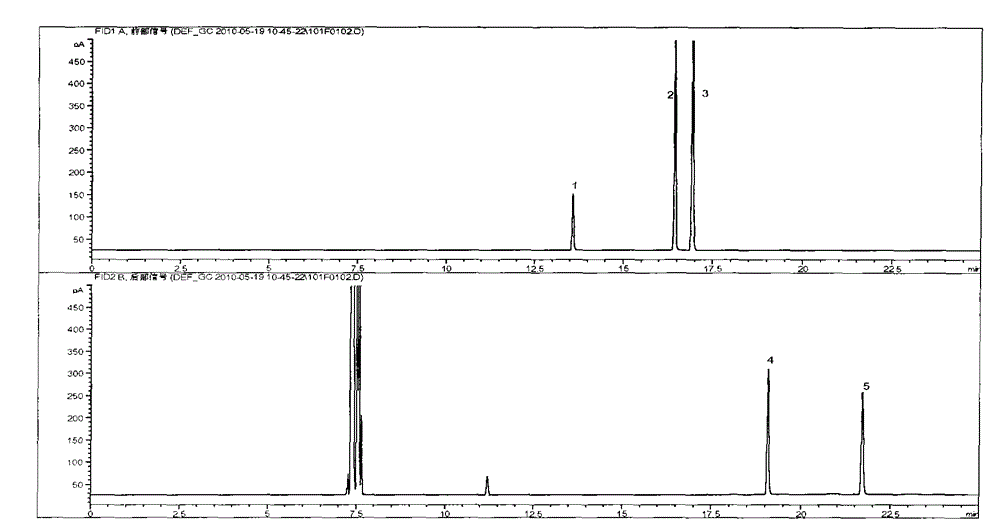

[0021] According to the flow chart of Figure 1, the standard samples I~V containing benzene, toluene, internal standard 2-pentanone, o-xylene and 1,2,4-trimethylbenzene were analyzed. The typical chromatographic analysis conditions are shown in Table 1. The composition of the samples is shown in Table 2. Calibration curves were drawn with standard samples I to V, and the calibration curves were used for quantitative calculation of actual samples. Then, the standard sample II was used as the sample to be tested, and the measurement was repeated 5 times. Quantitative calculations were carried out for benzene, toluene, o-xylene and 1,2,4-trimethylbenzene from the calibration curve, and the precision and accuracy of the method were investigated. Standard sample analysis results are shown in Table 3, and the chromatogram of standard sample I is shown in Table 3. figure 2 .

[0022] Table 1 Typical chromatographic analysis conditions

[0023]

[0024] Table 2 The composition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com