Integrated intelligent device for pest control and mould proof alcoholization of tobacco

An intelligent device and anti-mildew technology, applied in the fields of tobacco, tobacco processing, and application, can solve the problems of difficult insect killing, tobacco leaf residue, tobacco leaf loss, etc., and achieve the effect of complete alcoholization, consistent appearance and quality, and uniform quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

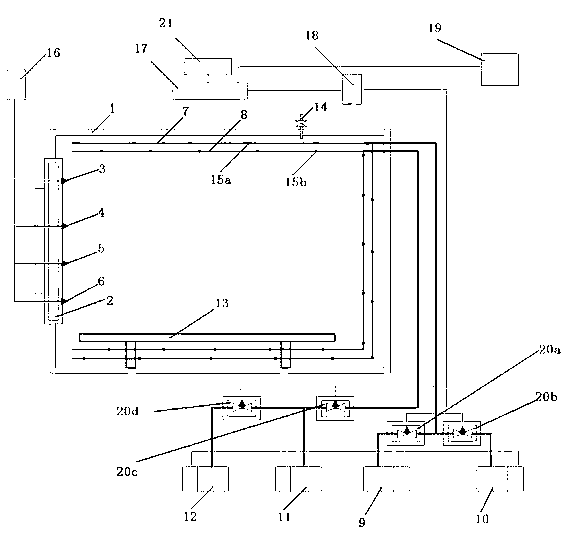

[0014] Embodiment 1: The inner dimension of the box 1 of the present invention is 1150cm×720cm×725cm (length×width×height), made of aluminum alloy, the middle is made of heat insulation material, the door is a swing door of the same material, and the size of the door is 650㎝×650㎝, the door leaf is tightly sealed, and the overall equipment can withstand positive and negative pressures of 0.1MPa-0.9MPa. A thermometer, pressure gauge, hygrometer and ozone detector are installed on the door leaf to detect the temperature, vacuum degree, Humidity and ozone content are directly connected to the computer, and the relevant data will be displayed on the display after being processed by the computer. A tobacco shelf is arranged on the bottom side of the box, and the size is 110cm×650cm, and the tobacco is placed on the shelf.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com