Water glass old sand refurbishing equipment and process thereof for refurbishing old sand

A water glass and used sand technology, which is applied in casting and molding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of high energy consumption, large initial investment, and large production line area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in combination with specific embodiments.

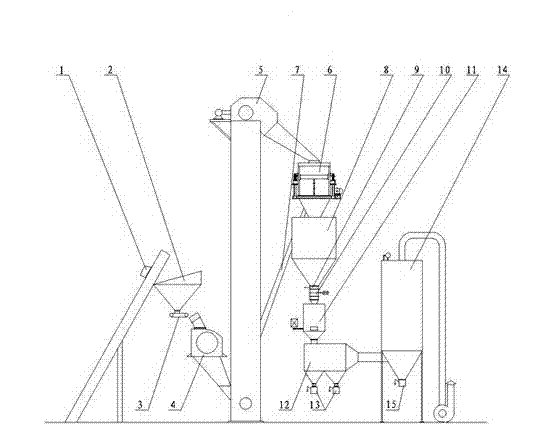

[0027] As shown in 1, a kind of sodium silicate old sand refurbishment equipment includes feeding device, and this refurbishment equipment also includes fine crusher 4, screening machine 6, peeling machine 11, classifier 12, belt type dust collector 14, described The feeding device is connected with the fine crusher 4, the fine crusher 4 communicates with the screening machine 6 through the bucket elevator 5, the screening machine 6 communicates with the chute 7, and the screening machine 6 communicates with the stripping machine 11 at the same time, and the stripping machine 11 is connected with the classifying machine. The classifier 12 is connected, and the bottom of the classifier 12 is provided with a gravity lock air discharge valve 13, and the classifier 12 is in communication with the belt dust collector 14.

[0028] The feeding device includes a feeding conveyo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com