Silicon-barium-aluminum alloy deoxidier and preparation method thereof

A technology of aluminum alloy and deoxidizer, which is applied in the field of steelmaking, can solve the problems of high cost and unsmoothness, and achieve the effects of smooth process, reduced content, and improved fluidity of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1: silicon barium aluminum alloy deoxidizer, the parts by weight of its composition raw material are: barite 22, quartz sand 52, siliceous shale 38, dolomite 12, bauxite 12, table salt 4, vermiculite 35, Sepiolite 22, attapulgite 8.

[0011] The raw materials are weighed according to the weight of the raw materials, put into the submerged arc furnace for smelting, the smelting temperature is 2200-2500°C, the smelting time is 2-3 hours, and the finished product is crushed to the particle size requirement: 5-80mm.

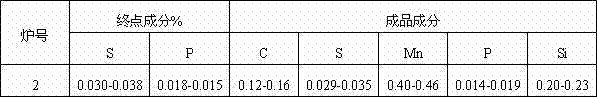

[0012] The following is the deoxidation test, the test steel is low carbon steel, used on the 2# furnace

[0013] Hot metal conditions:

[0014] [S]S% [P]% 0.038-0.032 0.190-0.155

[0015] Deoxygenation result:

[0016] serial number furnace number Addition amount of the present invention (kg) Oxygen content (PPm) 1 2-12807 20 39.25 2 2-12808 20 43.56 3 2-12809 20 39.35 4 2-12810 20 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com