Method for surface peeling of powder superalloy

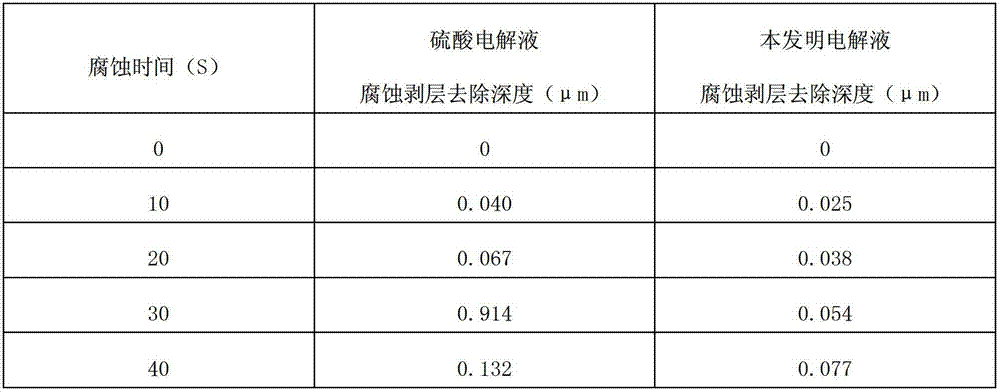

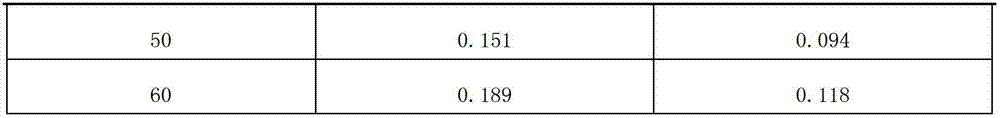

A high-temperature alloy and delamination technology, which is applied in the preparation of test samples, measuring devices, instruments, etc., can solve the problems of no obvious removal of delamination on the surface of powder superalloy, and can not meet the test requirements of residual stress on the surface of the sample. Eliminate the surface deformation disturbance layer, the removal effect is obvious, and the effect is easy to carry out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] This embodiment is a method for peeling off the surface of a FGH95 powder superalloy, and the specific process is:

[0017] Step 1, preparing a sample; the sample is a powdered nickel-based superalloy plate. The surface of the sample must be subjected to shot peening surface strengthening treatment; the shot peening intensity is 0.15A.

[0018] Step 2, preparing an electrolyte; the electrolyte is made of oxalic acid and distilled water, and the powdered oxalic acid is dissolved in distilled water and stirred until the powder oxalic acid is completely dissolved to obtain an electrolyte; the concentration of oxalic acid in the electrolyte is 5% , said percentage is mass content.

[0019] Step 3, corrode and peel off the layer; pour the prepared electrolyte into the electrolytic cell and heat it to 40°C and keep it warm. The sample to be corroded is completely immersed in the electrolyte. Turn on the power supply, adjust the voltage to 15V, the current to 1.5A, and turn...

Embodiment 2

[0021] This embodiment is a method for peeling off the surface of a FGH96 powder superalloy, and the specific process is:

[0022] Step 1, preparing a sample; the sample is a powdered nickel-based superalloy plate. The surface of the sample must be subjected to shot peening surface strengthening treatment; the shot peening intensity is 0.15A.

[0023] Step 2, preparing an electrolyte; the electrolyte is made of oxalic acid and distilled water, and the powdered oxalic acid is dissolved in distilled water and stirred until the powdered oxalic acid is completely dissolved to obtain an electrolyte; the concentration of oxalic acid in the electrolyte is 6% , said percentage is mass content.

[0024] Step 3, corrode and peel off the layer; pour the prepared electrolyte into the electrolytic cell and heat it to 35°C and keep it warm. The sample to be corroded is completely immersed in the electrolyte. Turn on the power supply, adjust the voltage to 15V, and the current to 1.5A. Th...

Embodiment 3

[0026] This embodiment is a method for peeling off the surface of a powdered FGH97 superalloy, and the specific process is:

[0027] Step 1, preparing a sample; the sample is a powdered nickel-based superalloy plate. The surface of the sample must be subjected to shot peening surface strengthening treatment; the shot peening intensity is 0.15A.

[0028] Step 2, preparing an electrolyte; the electrolyte is made of oxalic acid and distilled water, and the powdered oxalic acid is dissolved in distilled water and stirred until the powdered oxalic acid is completely dissolved to obtain an electrolyte; the concentration of oxalic acid in the electrolyte is 8% , said percentage is mass content.

[0029] Step 3, corrode and peel off the layer; pour the prepared electrolyte into the electrolytic cell and heat it to 30°C and keep it warm. The sample to be corroded is completely immersed in the electrolyte. Turn on the power supply, adjust the voltage to 15V, and the current to 1.5A. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com