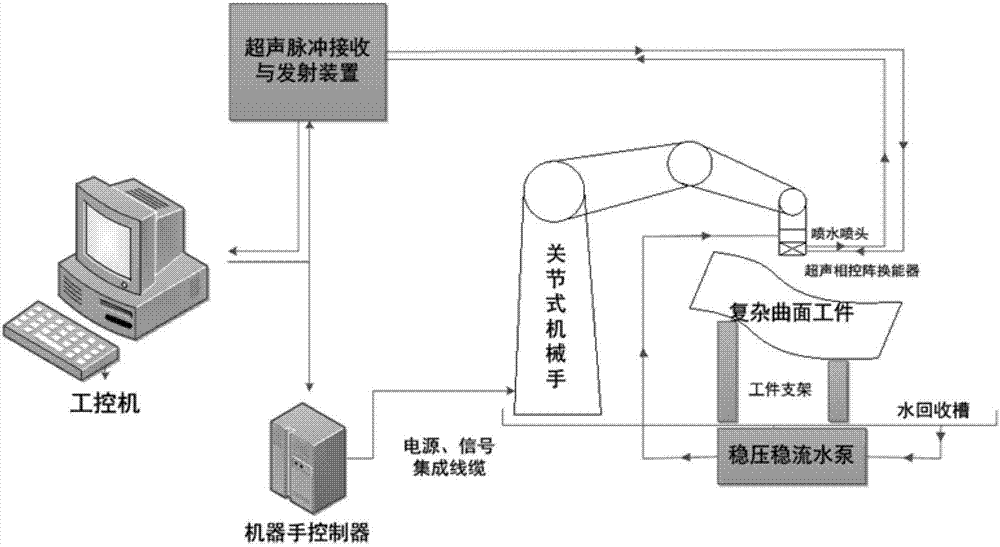

Single-manipulator automatic ultrasonic non-destructive detection device

A non-destructive testing and manipulator technology, which is used in measuring devices, analyzing solids using sonic/ultrasonic/infrasonic waves, and using sonic/ultrasonic/infrasonic waves for material analysis, etc. It can solve the problems of low detection efficiency and poor adaptability of complex surfaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The following is a detailed description of specific embodiments of the present invention.

[0009] The aforementioned industrial computer and the manipulator controller are connected by a network cable, which can transmit the control program and the point file of the manipulator movement; the manipulator controller and the manipulator are connected by a power supply and signal integration cable, which can provide power for the manipulator and provide the position of each joint of the manipulator parameters and signals of motion parameters. The articulated six-degree-of-freedom manipulator can move according to the signal provided by the controller. The working end of the manipulator has a flange, and the bracket of the sprinkler head is fixed on the flange. The phased array ultrasonic transducer is installed in the sprinkler head. The sprinkler head is divided into two parts. In the water tank; a part is a bracket, which is connected to the working end of the manipulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com