Optical film, polaroid, and liquid crystal display apparatus

A technology of optical film and cellulose acylate, applied in the field of optical film, can solve problems such as peeling, and achieve the effects of high durability, improved durability and good polarization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 101

[0287] (1) Film production of cellulose acylate film

[0288]

[0289] Cellulose acylate having an acetyl substitution degree of 2.87 was prepared. Here, sulfuric acid (7.8 parts by mass with respect to 100 parts by mass of cellulose) was added as a catalyst, carboxylic acid as a raw material of an acyl substituent was added, and an acylation reaction was performed at 40°C. In addition, after acylation, aging was performed at 40 degreeC. Then, the low molecular weight component of this cellulose acylate was washed and removed with acetone.

[0290]

[0291] (Preparation of solution 1 of cellulose acylate)

[0292] The following composition was put into the mixing box, and each component was melt|dissolved by stirring, and the cellulose acylate solution 1 was prepared.

[0293]

[0294]

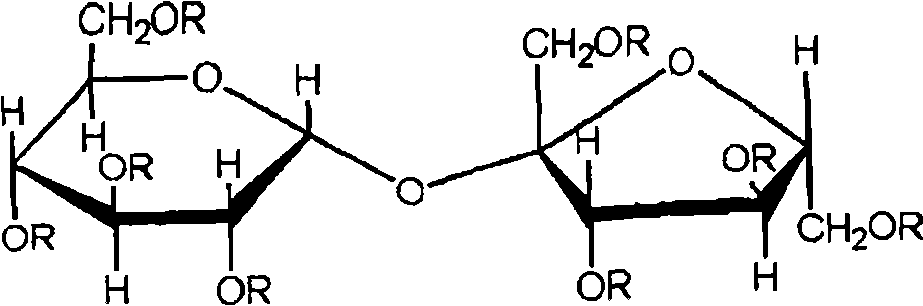

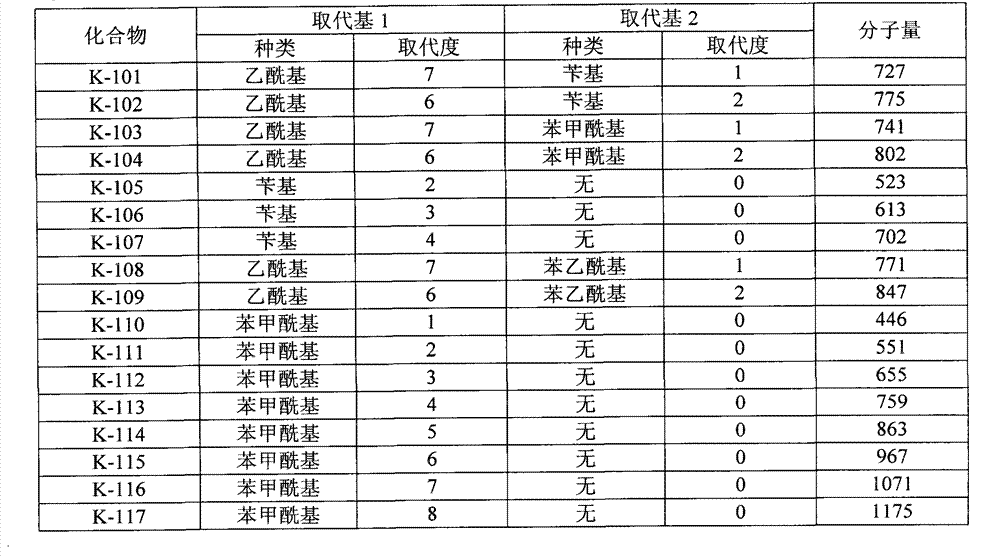

[0295] In addition, the sucrose benzoate used as the above-mentioned plasticizer uses 15 mol% or less of benzoyl substitutions with a degree of substitution of 8, and a total of 7...

Embodiment 102~118

[0335] [Preparation of Optical Films (Polarizer Protective Films) of Examples 102 to 118 and Comparative Examples 201 to 203]

[0336] Except for changing the type and amount of plasticizer added to cellulose acylate in Example 101, the film thickness, the type and addition of hindered amine compound added to the active energy ray-cured layer as described in Table 8, Except the amount, the optical film (polarizer protective film) of Examples 102-118 and Comparative Examples 201-203 was manufactured similarly.

[0337] In addition, in following Table 8, the addition amount of a plasticizer shows the mass parts with respect to 100 mass parts of cellulose acylate resins. In addition, in the following Table 8, sucrose benzoate means that the substitution body with a degree of substitution of benzoyl group of 8 is 15 mol% or less, the total number of substitution bodies with a degree of substitution of 7 to 6 is 70 mol% or less, and the substitution degree The sucrose benzoate who...

Embodiment 301

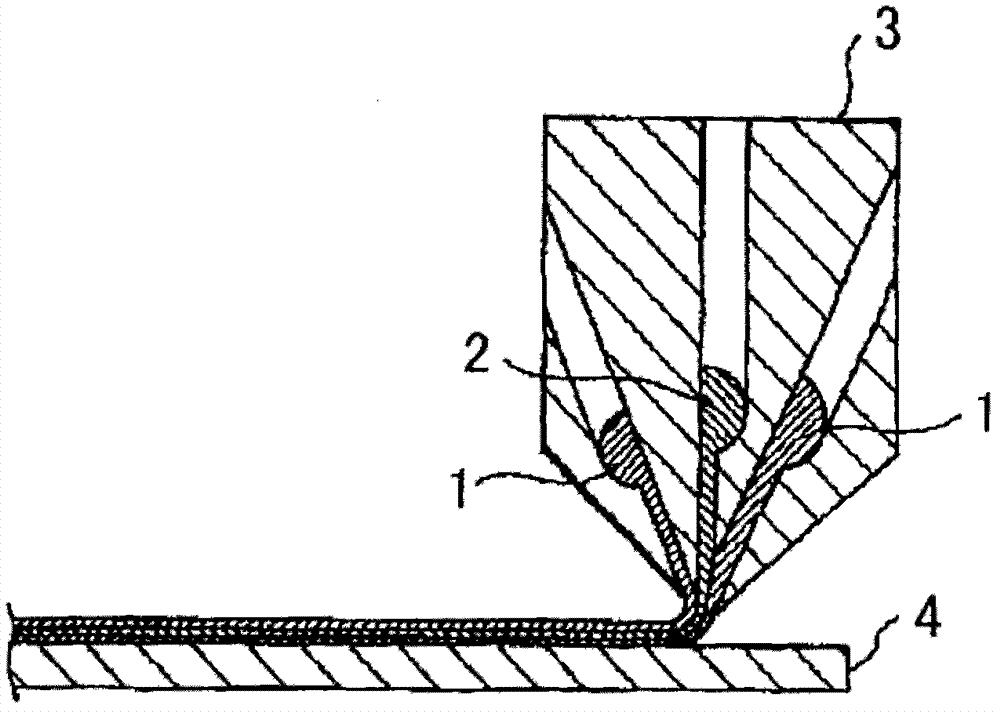

[0362] [Production of liquid crystal display device]

[0363] Peel off the polarizing plate on the viewer side of a commercially available liquid crystal television (BRAVIA J5000 from SONY Corporation), and place the polarizing plate of the present invention using the polarizing plate protective film of Example 101 according to the polarizing plate protective film of Example 101. The form on the liquid crystal cell side is pasted via an adhesive. The transmission axis of the polarizing plate on the viewer side is arranged in the up-down direction. Moreover, the liquid crystal display device of the comparative example was produced similarly except having used the polarizer protective film of the comparative examples 201-203. Compared with the liquid crystal display devices using the polarizing plate protective films of the comparative examples, the liquid crystal display device of the present invention produced in this way has less deterioration in display performance even if ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com