a foam oil repellent

A technology of foam flooding and surfactant, which is applied in the field of foam flooding agents, can solve the problems of decreased permeability, environmental hazards, and serious emulsification of crude oil, etc., and achieve the goals of reducing oil-water interfacial tension, stable product performance, and changing wettability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

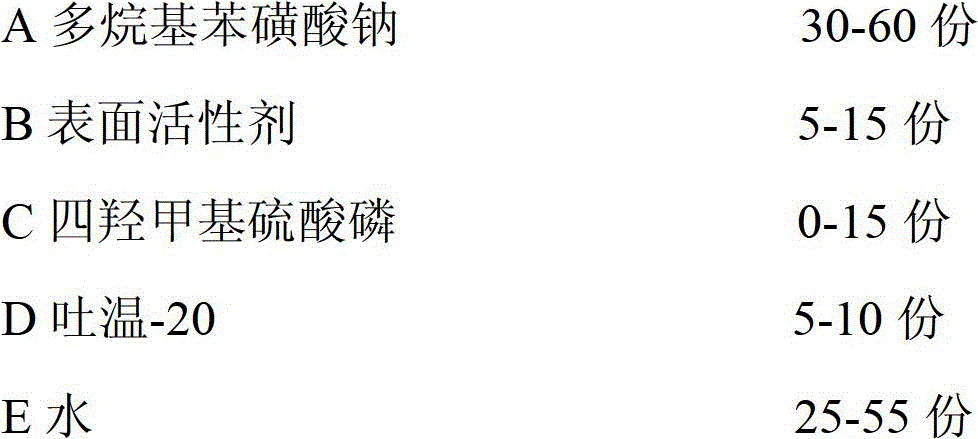

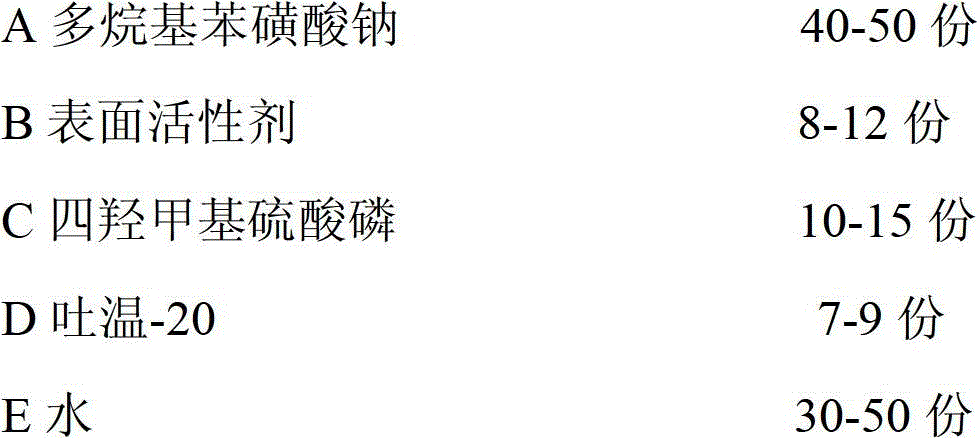

Method used

Image

Examples

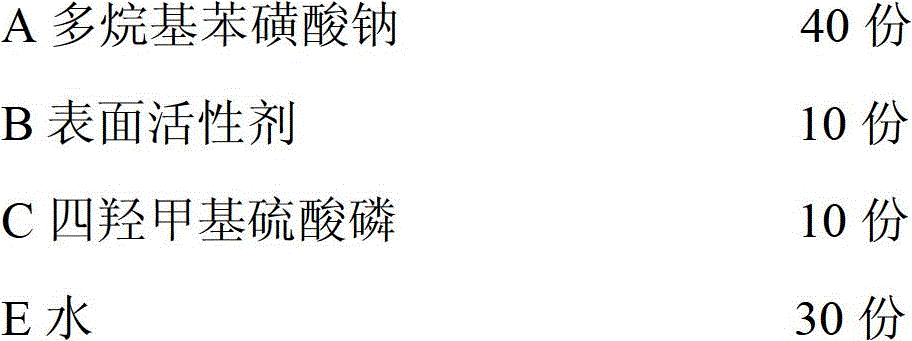

Embodiment 1

[0036] In the stirred tank, add 200Kg of sodium polyalkylbenzene sulfonate, add 150Kg of water and stir evenly, heat up to 50°C, add 50Kg of sodium tridecyl polyoxyethylene ether carboxylate, and then add 50Kg of tetrakis hydroxymethyl phosphorus sulfate, Stir well and serve.

[0037] The oil displacing agent of Example 1 was subjected to a fog film test, and the results are shown in the following table, including two parallel experiments.

[0038]

[0039] In addition, compared with other existing foam oil displacement agents, the oil displacement agent of this example has a foam half-life of 400 minutes at 50°C and a foam volume of 330 mL. It has good compatibility with other surfactants, and the indoor simulation improves the recovery by more than 15%.

Embodiment 2

[0041] Add component A: polyalkylbenzene sulfonate sodium 200Kg into the reaction kettle, add water 215Kg, stir evenly, add component B: tridecyl polyoxyethylene ether carboxylate sodium 50Kg and component D Tween 35Kg and stir Evenly, that is.

Embodiment 3

[0043] Add 200Kg of component A sodium polyalkylbenzene sulfonate into the reaction kettle, add 250Kg of component water, stir evenly, add 50Kg of component B cocamidopropyl betaine, stir evenly, and obtain.

[0044] The R of the polyalkylbenzene sulfonate sodium that above-mentioned embodiment 1-3 selects for use 3 for C 4 h 9 , R 2 for C 7 h 15 , R 1 for C 7 h 15 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| half-life | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com