Magnetic flux leakage defection machine of oil sleeve

An oil casing and flaw detector technology, applied in the direction of material magnetic variables, can solve problems such as high power consumption, folding, and maintenance difficulties, and achieve the effects of improving service life, convenient and flexible detection, and obvious effect advantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

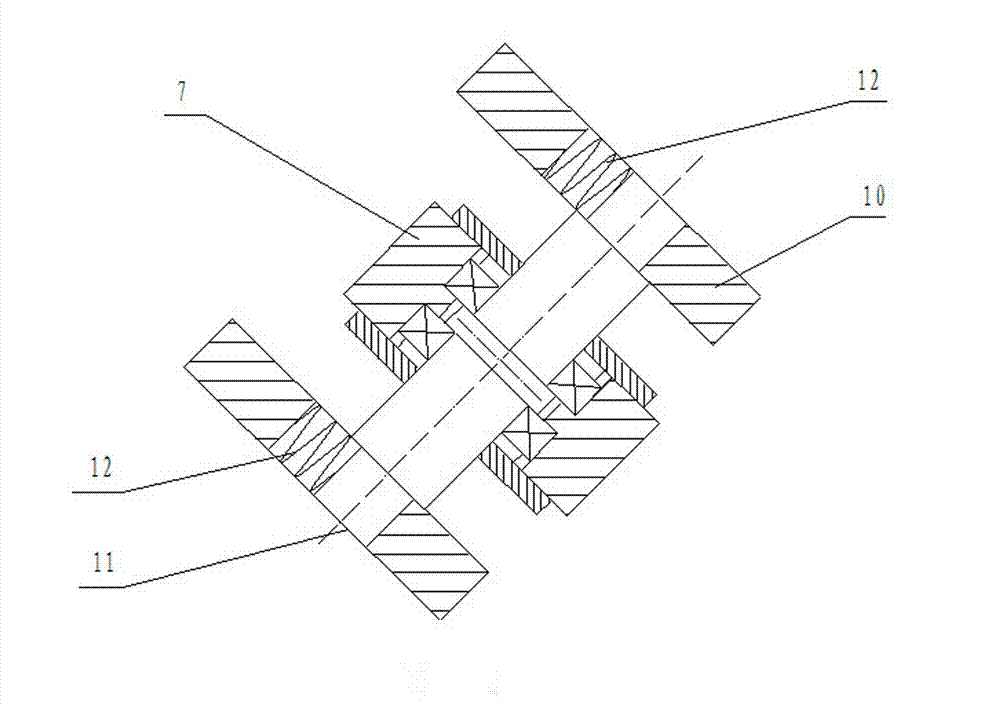

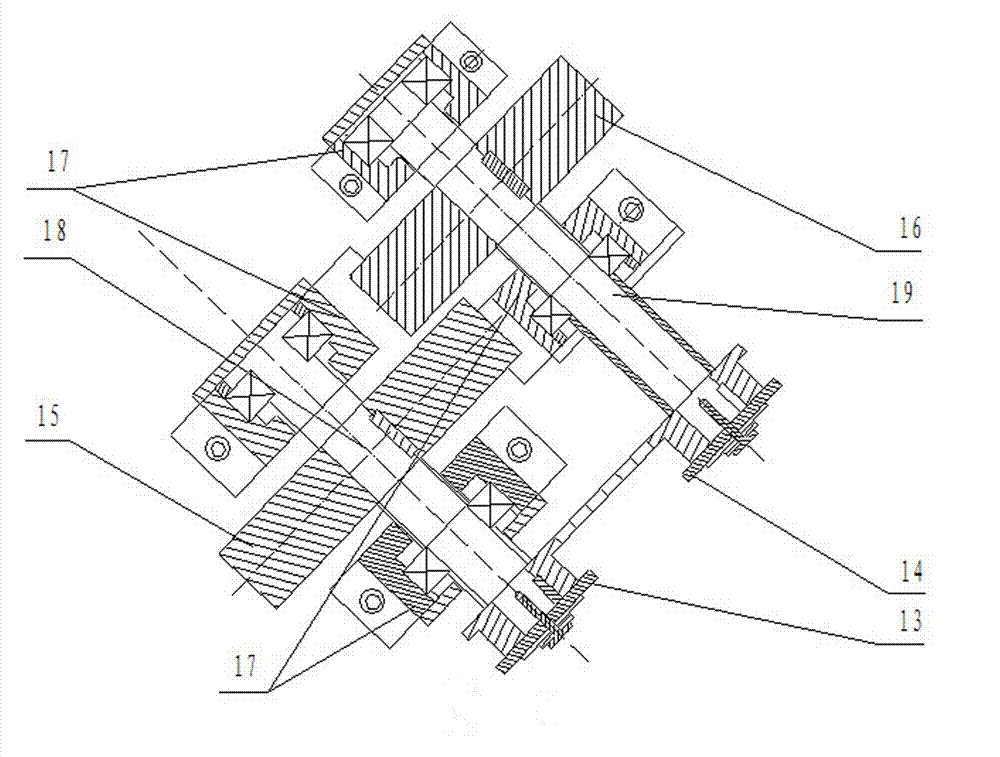

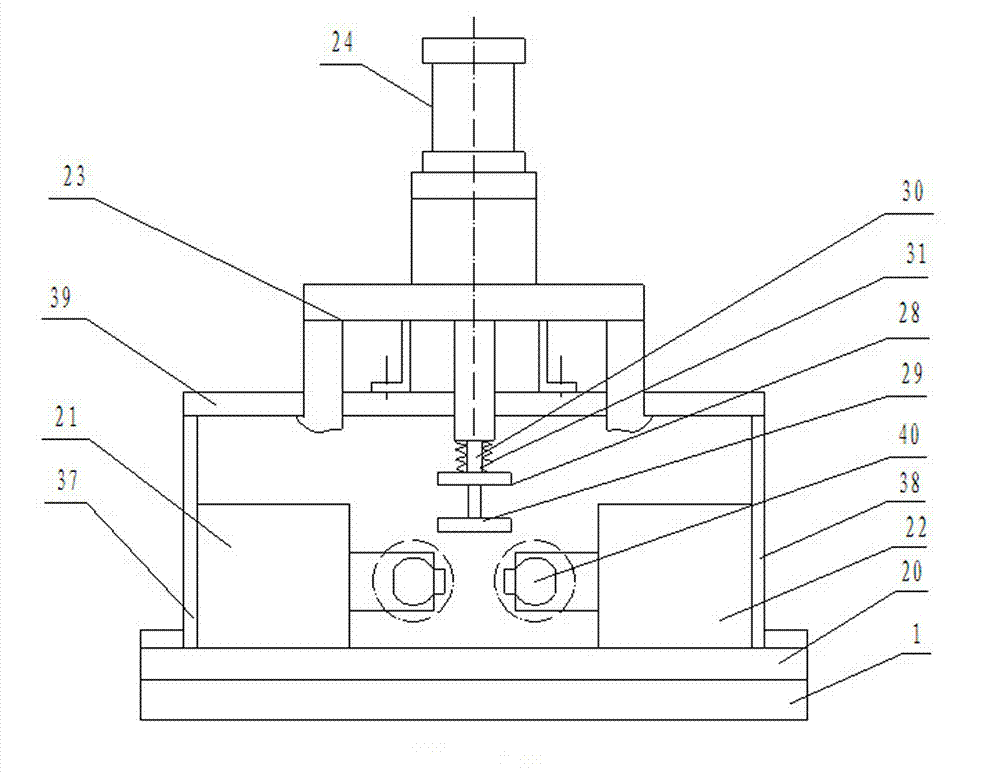

[0029] The magnetic flux leakage flaw detector of the invention will be further described in detail below in conjunction with the accompanying drawings.

[0030] Depend on figure 1 It can be seen that a kind of oil casing magnetic flux leakage flaw detection machine in this embodiment includes a control cabinet, a computer, an assembly line detection system and a marking machine, and the control cabinet is respectively connected with the computer, the assembly line detection system and the marking by signal lines; Signal amplification circuit, noise elimination circuit, signal processing circuit, the assembly line detection system includes an infrared monitoring sensor, the electrical signal of the casing defect detected by the infrared monitoring sensor on the assembly line detection system is divided into two parts after passing through the signal amplification circuit and the noise elimination circuit. One route signal processing circuit is driven by a computer to accuratel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com