Process and device of fluidized bed for synthesis gas methanation

A fluidized bed, gas methane technology, applied in the chemical/physical/physical chemical process of energy application, gas fuel, organic chemistry, etc. It can improve the fluidization quality, reduce catalyst loss, and prevent cohesion and flow loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

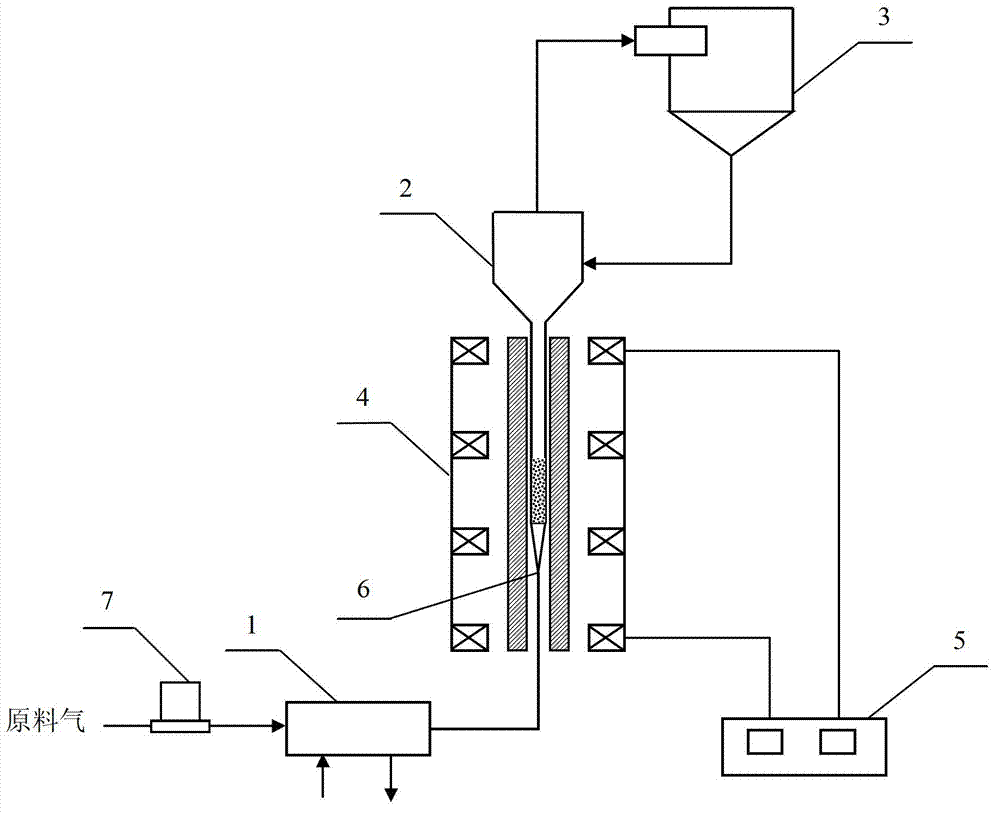

[0042] Embodiment 1 Fluidized bed device for syngas methanation

[0043] The device includes a preheater 1, a magnetic field fluidized bed and a cyclone separator 3 connected in sequence from low to high. The magnetic field fluidized bed is composed of a fluidized bed reactor 2 and a magnetic field generator 4 nested outside the fluidized bed reactor 2 . The magnetic field generator 4 is a one-dimensional axial magnetic field generator, which is connected with a constant current power supply controller 5 . The outlet of the preheater 1 is connected with the gas inlet 6 of the fluidized bed reactor 2 through a pipeline, and the inlet of the cyclone separator 3 is connected with the outlet of the fluidized bed reactor 2 through a pipeline. A mass flow meter 7 is arranged between the front of the preheater 1 .

Embodiment 2

[0044] The fluidized bed process of embodiment 2 synthesis gas methanation

[0045] use as figure 1 The fluidized bed device diagram of the shown syngas methanation, the specific operation steps are as follows:

[0046] with H 2 and CO as raw gas (H 2 The molar ratio to CO is 3.0), feed the raw material gas into the preheater for preheating, the temperature of the preheated raw material gas is 290°C, and the preheated raw material gas enters from the gas inlet at the bottom of the magnetic field fluidized bed reactor Pass into the fluidized bed reactor, so that the catalyst particles in the fluidized bed reactor are in a fluidized state, and the gas velocity of the raw material gas is 0.01m / s; in the magnetic field fluidized bed, the raw material gas fully contacts and reacts with the catalyst particles ;The operating temperature of the reactor is controlled between 400~420°C, the operating pressure is 0.1MPa, and the volume space velocity of the raw material gas is 30,000h...

Embodiment 3

[0048] The fluidized bed process of embodiment 3 synthesis gas methanation

[0049] use as figure 1 The fluidized bed device diagram of the shown syngas methanation, the specific operation steps are as follows:

[0050] with H 2 and CO as raw gas (H 2 The molar ratio to CO is 3.5), feed the raw material gas into the preheater for preheating, the temperature of the preheated raw material gas is 230°C, and the preheated raw material gas enters from the gas inlet at the bottom of the magnetic field fluidized bed reactor Pass into the fluidized bed reactor, so that the catalyst particles in the fluidized bed reactor are in a fluidized state, and the gas velocity of the raw material gas is 1.0m / s; in the magnetic field fluidized bed, the raw material gas and the catalyst particles fully contact and react ;The operating temperature of the reactor is controlled between 340~360°C, the operating pressure is 3MPa, and the volume space velocity of the raw material gas is 60,000h -1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com