Modified bismaleimide resin and preparation method thereof

A bismaleimide resin and bismaleimide technology, applied in the field of composite materials, can solve the toughening instability of thermosetting resins, the uncontrollable degree of siloxane hydrolysis, and the rapid growth rate of resin viscosity, etc. problems, to achieve the effect of comprehensive performance improvement, good solvent solubility and reactivity, and low melt viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

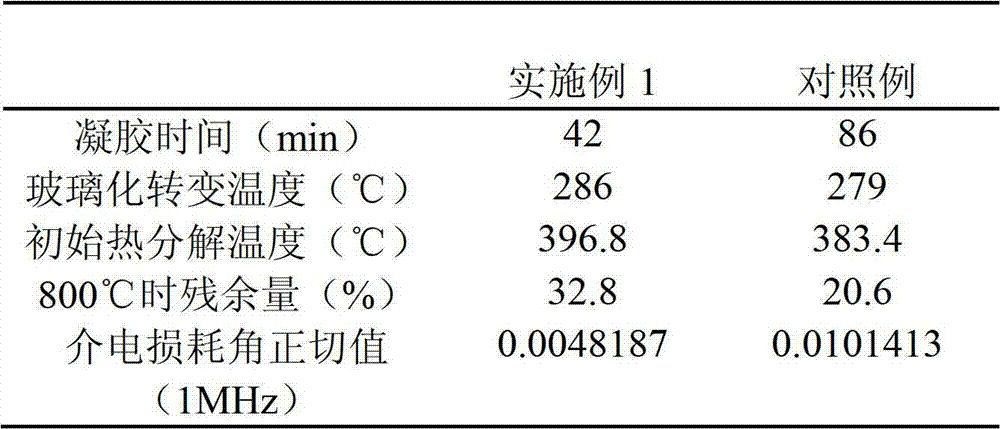

[0017] Put 100g of N,N'-4,4'-diphenylmethane bismaleimide, 43g of diallyl bisphenol A and 6.3g of N-(β-aminoethyl)-γ-aminopropyl Stir and mix evenly at room temperature, raise the temperature to 50°C, and react in this environment for 90 minutes; raise the temperature to 140°C, and react for 40 minutes under the condition of stirring, and obtain a modified permanent bismaleimide resin.

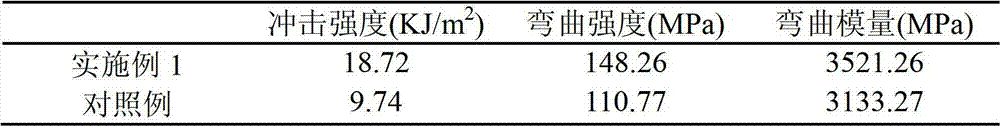

[0018] After the above modified bismaleimide resin is cured at 140°C / 2h, 160°C / h, 180°C / 2h and 200°C / 2h and post-cured at 240°C / 4h, the modified bismaleimide resin is obtained. Imide cured resin.

Embodiment 2

[0029] Put 100g of N,N'-4,4'-diphenylmethane bismaleimide, 43g of diallyl bisphenol A and 6.3g of N-(β-aminoethyl)-γ-aminopropyl Stir and mix evenly at room temperature, raise the temperature to 50°C, and react in this environment for 90 minutes; raise the temperature to 140°C, and react for 40 minutes under the condition of stirring, and obtain a modified permanent bismaleimide resin. After the resin is cured at 140°C / 2h, 160°C / 2h, 180°C / 2h and 200°C / 2h and post-cured at 240°C / 4h, a modified bismaleimide cured resin is obtained.

Embodiment 3

[0031] Put 100g of N,N'-4,4'-diphenylmethane bismaleimide, 43g of diallyl bisphenol A and 6.3g of N-(β-aminoethyl)-γ-aminopropyl Triethoxysilane was stirred and mixed evenly at room temperature, raised to 50°C, and reacted in this environment for 90 minutes; raised to 140°C, reacted for 40 minutes under stirring conditions, and obtained a Modified bismaleimide resin. After the resin is cured at 140°C / 2h, 160°C / h, 180°C / 2h and 200°C / 2h and post-cured at 240°C / 4h, a modified bismaleimide cured resin is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com