Multifunctional coking delaying corrosion inhibitor and preparation method thereof

A technology of delayed coking and corrosion inhibitor, which is used in cracking, non-catalytic thermal cracking, and anti-corrosion during distillation. Operation period, effect of inhibiting salt formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

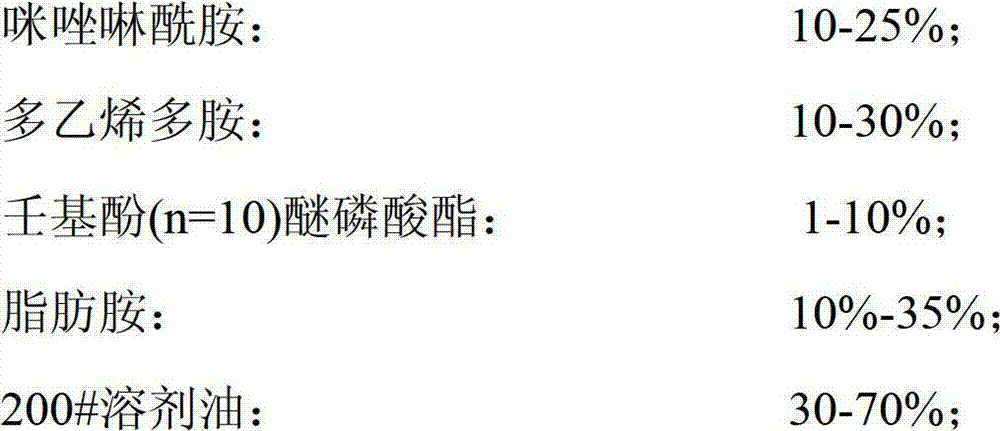

Embodiment 1

[0025] A preparation method of a delayed coking multifunctional corrosion inhibitor, comprising the steps of:

[0026] Pump 270g of 200# solvent oil, 200g of imidazoline amide, 100g of polyvinylpolyamine, and 300g of octadecylamine into the stirring tank in sequence, and the stirring speed is 350r / min. After stirring for 30min, add 30g of nonylphenol (n=10) phosphate In the stirred tank, continue to stir for 25 minutes, and pack into products.

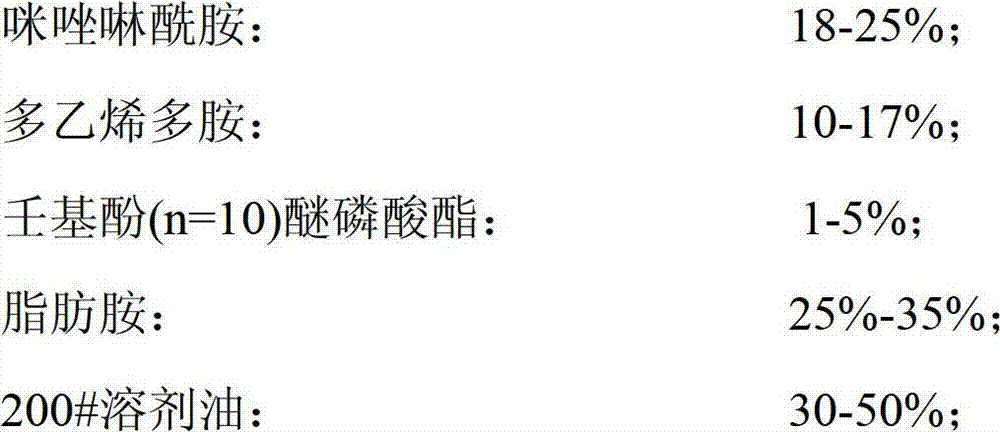

Embodiment 2

[0028] A preparation method of a delayed coking multifunctional corrosion inhibitor, comprising the steps of:

[0029] Pump 400g of 200# solvent oil, 190g of imidazoline amide, 110g of polyethylene polyamine, and 250g of octadecylamine into the stirring tank in sequence, and the stirring speed is 350r / min. After stirring for 30min, add 50g of nonylphenol (n=10) phosphate In the stirred tank, continue to stir for 25 minutes, and pack into products.

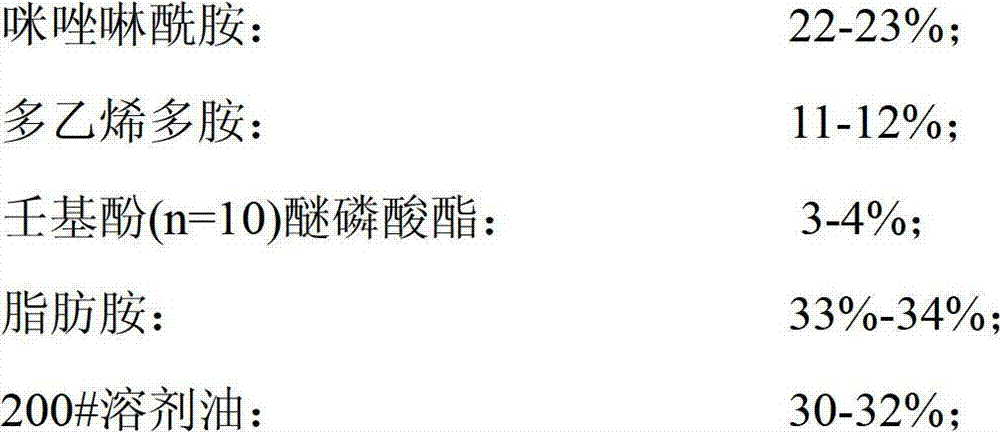

Embodiment 3

[0031] A preparation method of a delayed coking multifunctional corrosion inhibitor, comprising the steps of:

[0032] Pump 310g of 200# solvent oil, 210g of imidazoline amide, 150g of polyvinylpolyamine, and 290g of octadecylamine into the stirring tank in sequence, and the stirring speed is 350r / min. After stirring for 30min, add 40g of nonylphenol (n=10) phosphate In the stirred tank, continue to stir for 25 minutes, and pack into products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com