Combing textile process and combing head structure thereof

A technology of combing head and process, applied in the direction of combing machine, textile and papermaking, fiber processing, etc., to achieve the effect of reducing machine parts loss and energy consumption, increasing speed and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] A kind of combed textile process it comprises the following steps:

[0025] (1) Feeding, that is, feeding raw materials into the traction mechanism of the combing machine;

[0026] (2) Separation, which is to separate the raw materials to be fed;

[0027] (3) combing, that is, combing the separated raw materials;

[0028] (4) Overlapping, which is to overlap the combed raw materials to obtain finished products.

[0029] The combing in said step 3 is bidirectional combing.

[0030] The overlapping in step 4 is longitudinal overlapping.

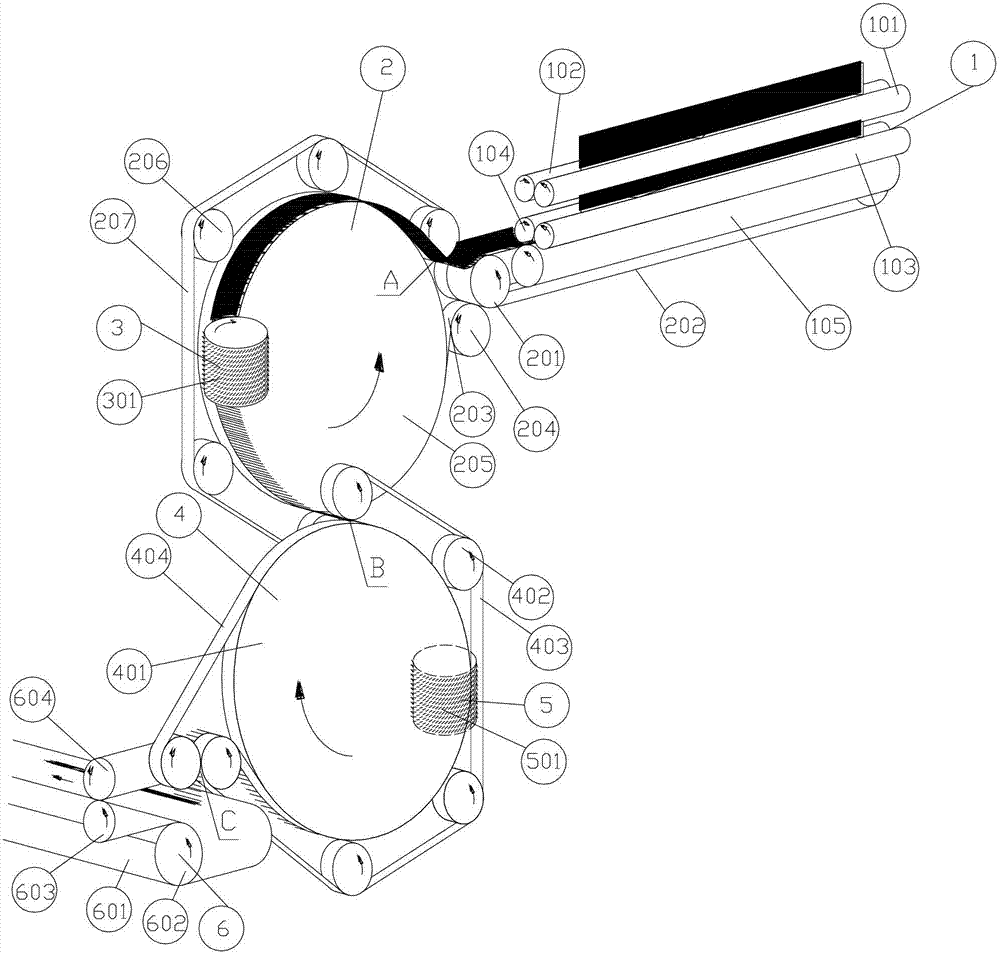

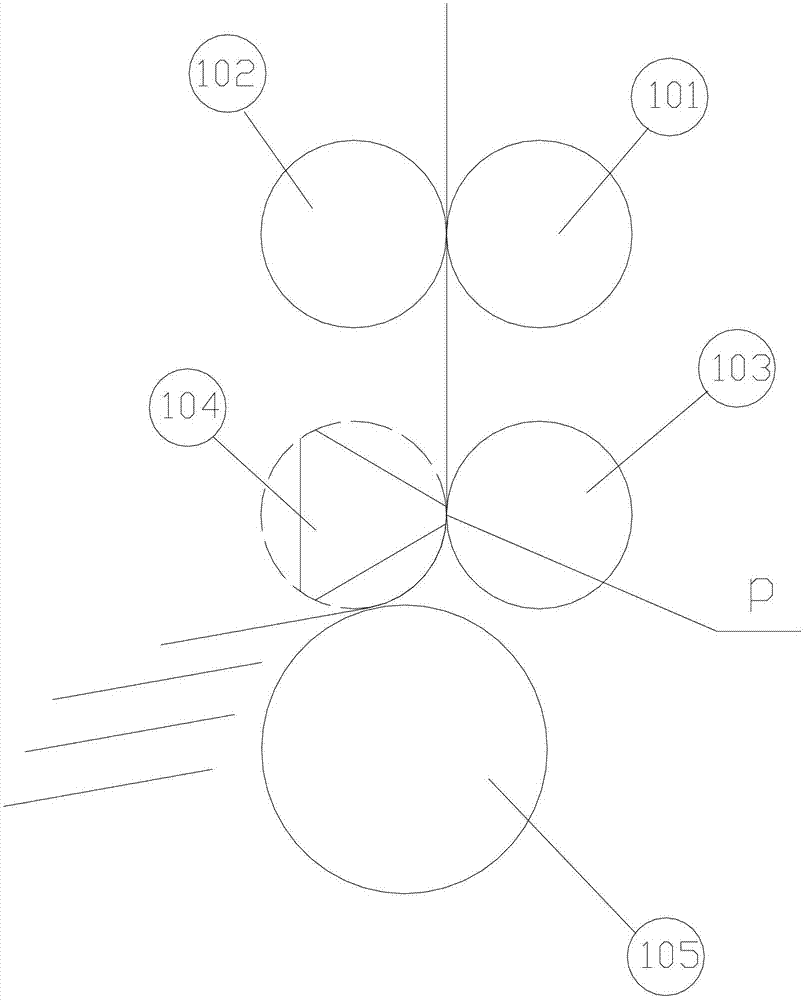

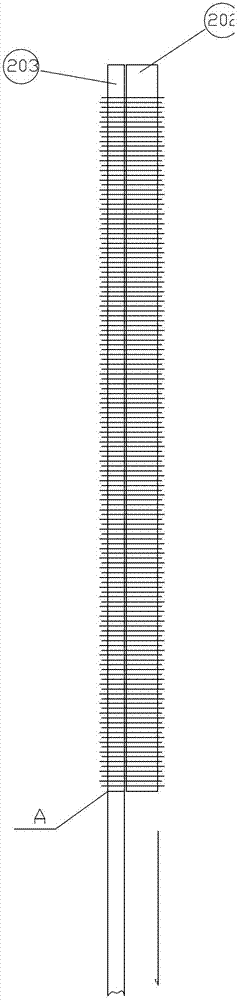

[0031] In order to realize above-mentioned combed textile technology, the present invention designs a kind of combing head structure of combing machine, as attached figure 1 As shown, it includes a drafting separation mechanism 1, and the drafting separation mechanism 1 is connected with an upper compound whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com