Filter with silencing function and air conditioner using such filter

A filter and function technology, applied in the field of air conditioners, can solve the problems of inability to eliminate refrigerant cavitation noise, inability to meet the miniaturization of air conditioners, and complex processing, so as to reduce airflow impact noise, improve comfort, and reduce cavitation noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

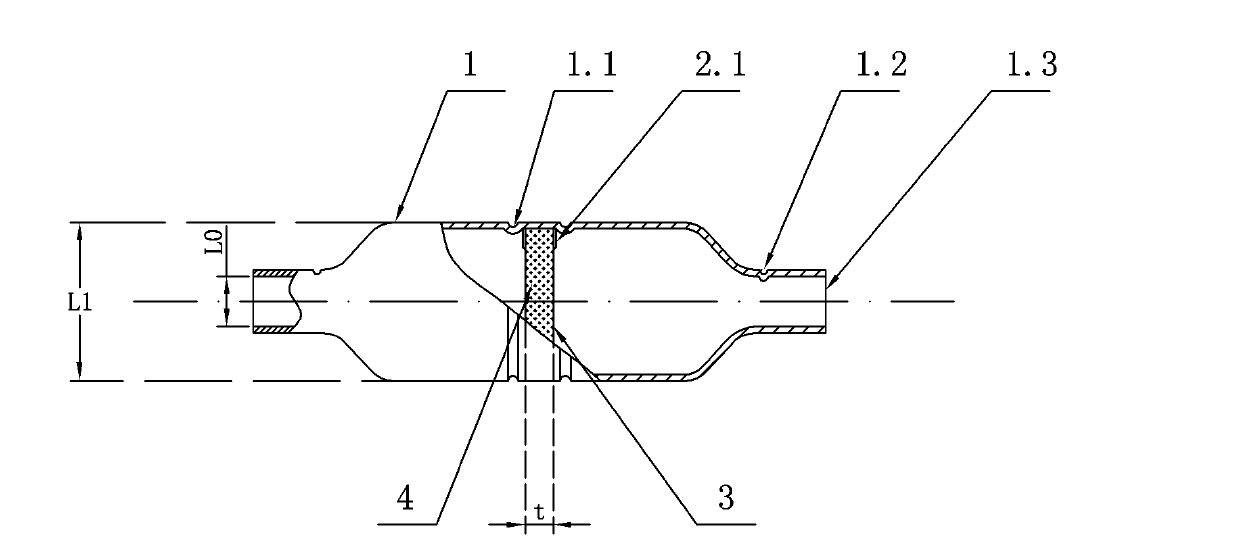

[0024] see figure 2 , a filter with noise reduction function, comprising a shell 1, the shell is a hollow cylinder, both ends shrink inwardly to form an interface 1.3, the ratio of the inner diameter L1 of the shell to the inner diameter L0 of the interface is greater than 1.5. Protrusions 1.1 are provided in the middle of the inner side of the housing 1 . The silk screen layer 4 used for noise reduction is arranged between two layers of filter screens 3, and the filter screen and the screen layer 4 are fixed by clamps 2.1 to form a filter noise reduction layer. The filter sound-absorbing layer is fixed in the middle of the housing 1 through the bumps 1.1. The screen layer is made of SUS wire which has no chemical reaction with the refrigerant, and its thickness t is 0.5mm-20mm. The inner side of the interface 1.3 is provided with a positioning point 1.2, and the positioning point is used to ensure the depth and consistency of the intubation tube inserted into the filter. ...

no. 2 example

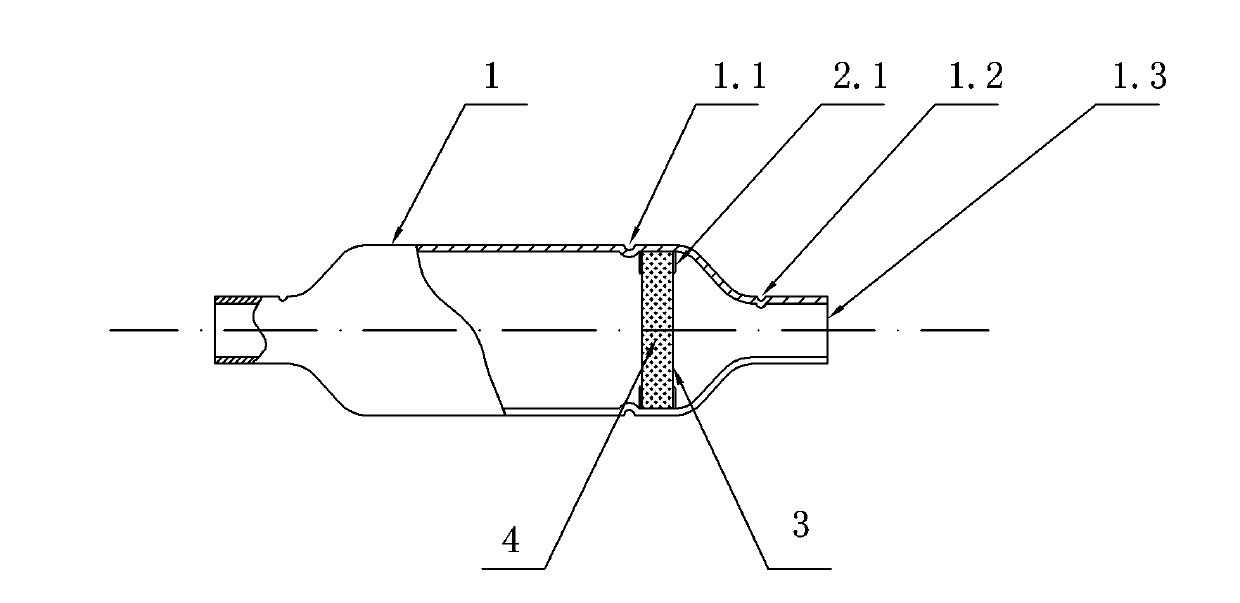

[0026] see image 3 , a filter with a sound-absorbing function, the filtering sound-absorbing layer composed of a wire mesh layer 4 and a filter net 3 is arranged at a position close to the interface 1.3 in the housing. Use the shoulder formed by the inward contraction of the shell 1 to limit one side of the filter sound-absorbing layer; the other side of the filter sound-absorbing layer is limited by the convex point 1.1 set on the inside of the shell 1, so that it is fixed on the shell in vivo. Compared with the first embodiment, this design reduces the number of bumps 1.1 and simplifies the production process. Other unmentioned parts are the same as the first embodiment.

no. 3 example

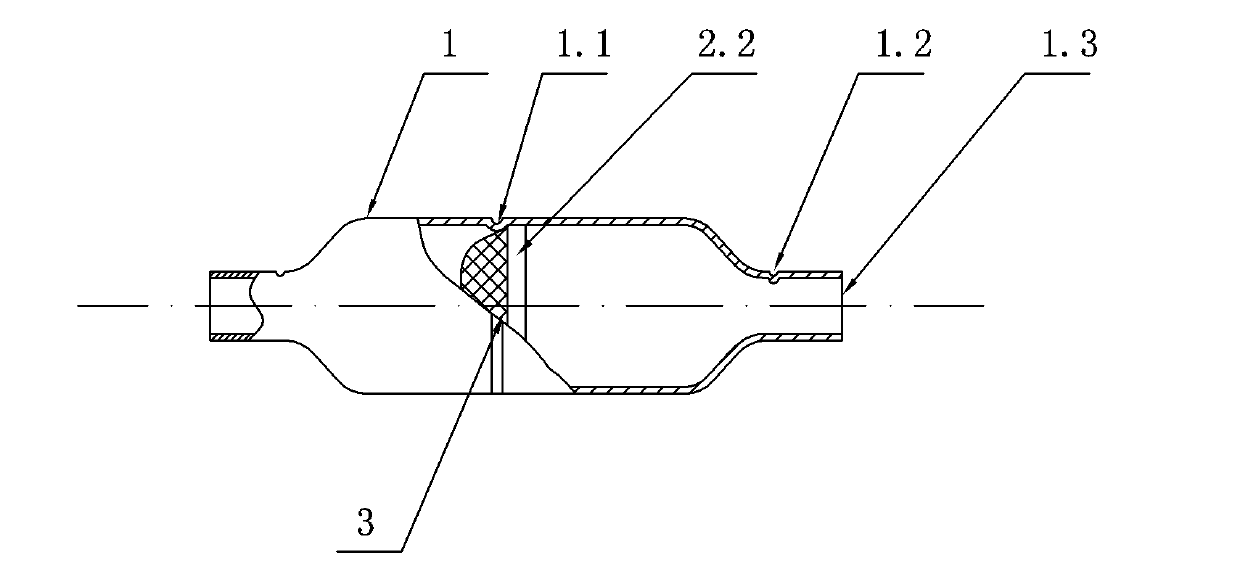

[0028] see Figure 4 , a filter with noise reduction function, two layers of screens 3 are provided with two layers of wire mesh layer 4, and each layer of filter screen 3 half-wraps the mesh layer 4 of its adjacent wire; between the two layers of wire mesh layers A fixing piece 2.2 is arranged between them, and each layer of silk screen 4 is fixed with the fixing piece 2.2 through the adjacent filter mesh 3 . The silk screen layer, the filter screen and the fixing piece are fixed in the middle of the housing through the bumps 1.1. Other unmentioned parts are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com