Metal wire for improving strength and corrosion resistance and preparation method thereof

A metal wire, strength-enhancing technology with applications in condensed matter physics and materials science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

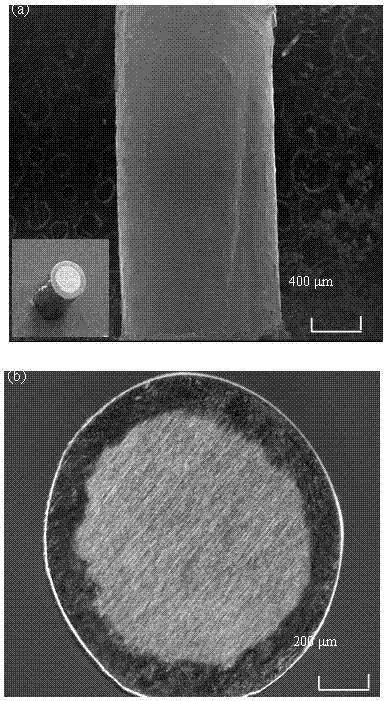

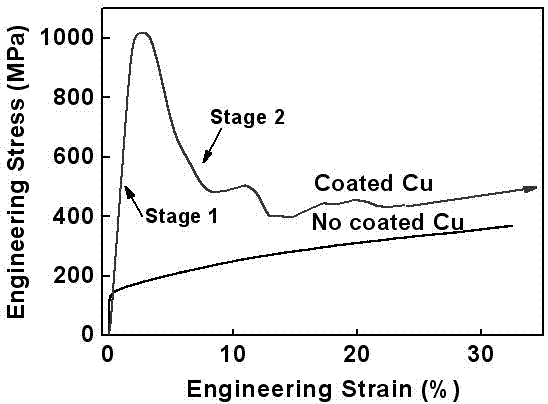

[0031] The metal wire with improved strength and corrosion resistance of the present invention is provided with a layer of metallic glass coating on the surface of the metal wire body. Metallic glass coating preferably Zr 41.25 Ti 13.75 Ni 10 Cu 12.5 be 22.5 coating, the metal wire body is preferably a copper wire, and the diameter of the metal wire body is 0.2mm--5mm.

[0032] The preparation method of the metallic wire with metallic glass coating of the present invention is,

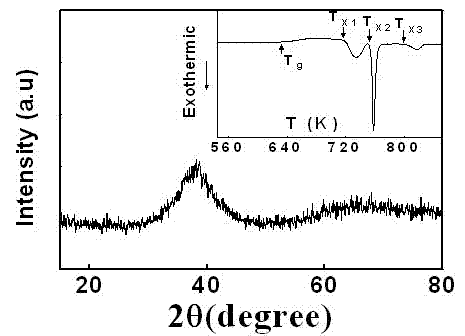

[0033] 1) First, place the metallic glass ingot in an electric arc furnace filled with inert gas, and use electric arc to repeatedly smelt it to become a liquid metallic glass with uniform composition; the purpose of the inert gas environment is to make the metallic glass not easy to be oxidized. The obtained argon creates a stable environment. At the same time, in order to make the compositi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com